A preparation method of a nanoporous gold film and a silicon substrate using the film

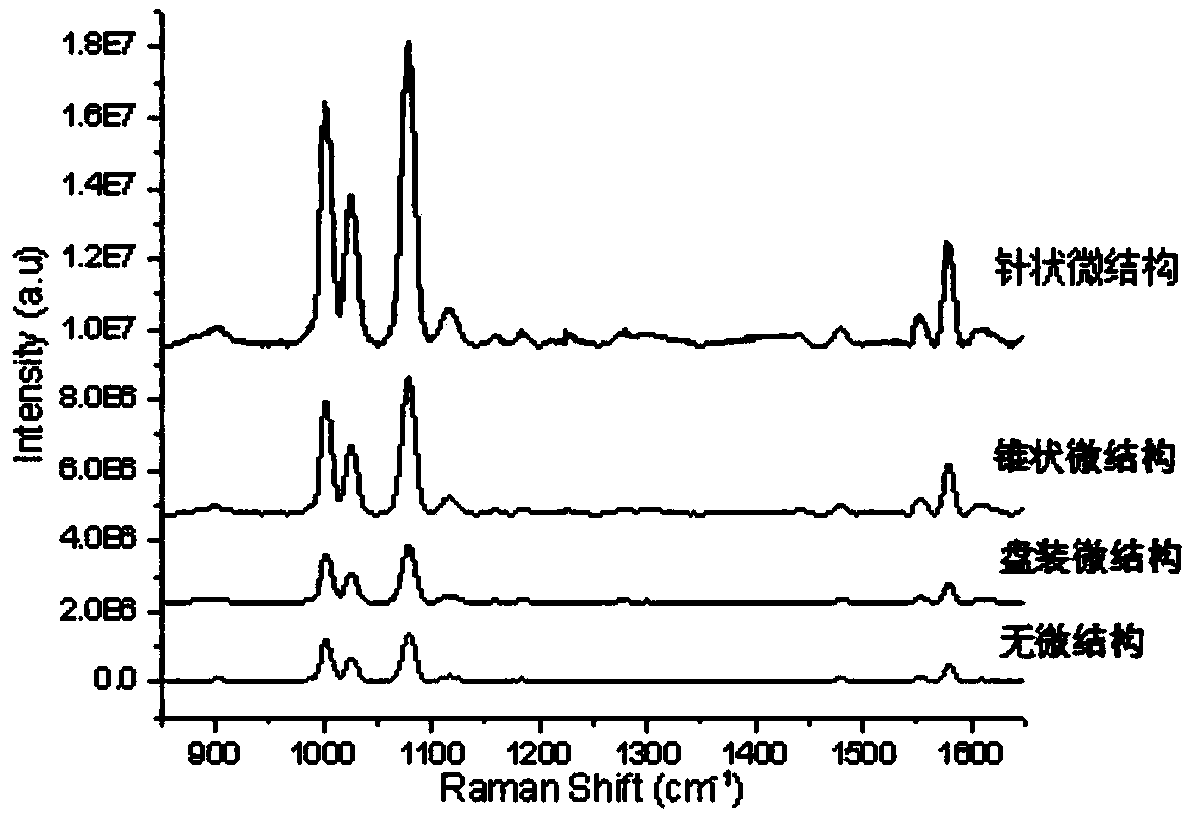

A manufacturing method and nanopore technology, which are applied in the manufacture of microstructure devices, metal material coating processes, processes for producing decorative surface effects, etc. Raman Spectroscopy Characterization Weak Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

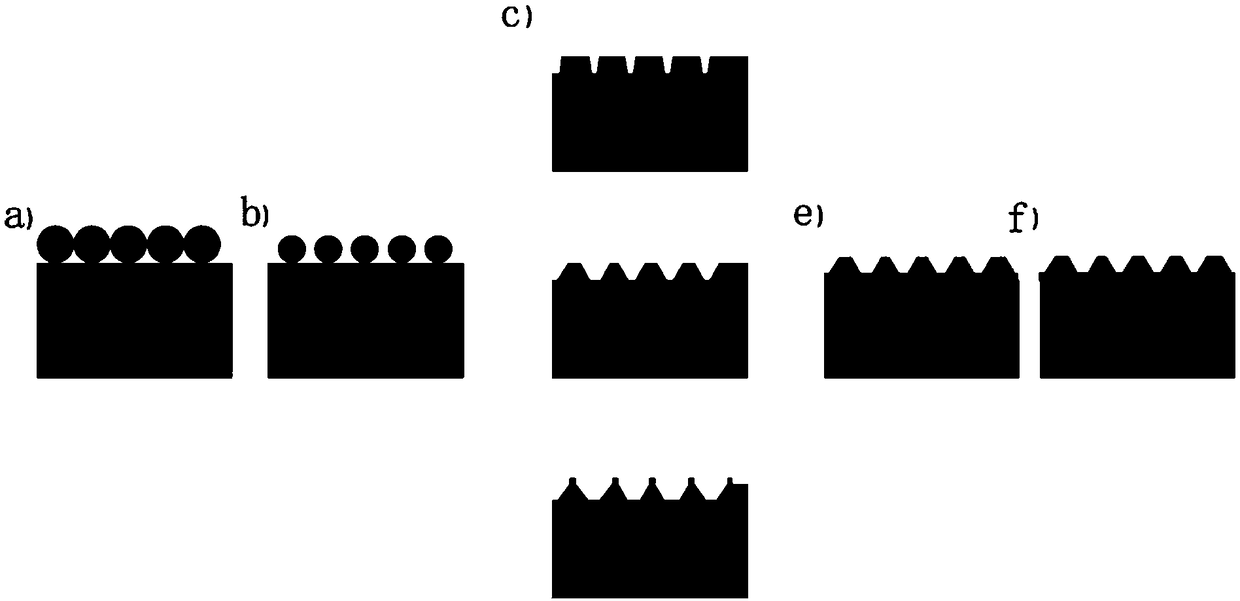

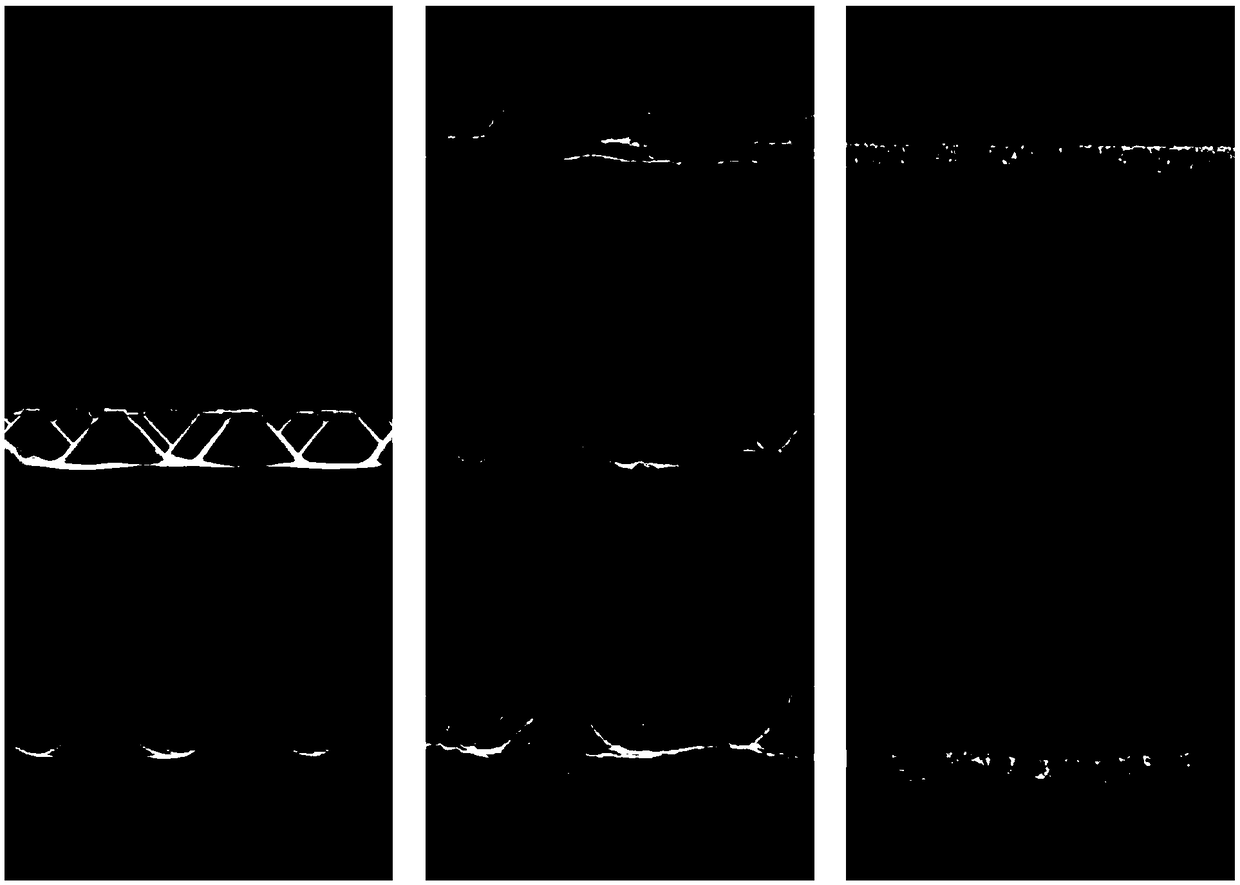

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 Shown, a kind of preparation method of nanoporous gold thin film and the silicon base that uses this thin film, comprise the silicon chip to be processed, the preparation method of microstructure nanoporous gold thin film comprises the following steps:

[0028] a. A uniform single-layer polystyrene microsphere layer is formed on the surface of the silicon wafer, and the single-layer polystyrene microsphere layer is used to protect the surface of the silicon wafer where the microsphere layer is located from being affected by the etching gas.

[0029] b. Use oxygen plasma to reduce the diameter of polystyrene microspheres to ensure the microsphere gap. The size of the microsphere gap directly affects the microstructure etched on the subsequent silicon wafer.

[0030] c. Etching microstructures on the silicon wafer, and etching different microstructures by control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com