Molybdenum disilicide coated tantalum boride-hafnium carbide spherical powder and preparation method thereof

A spherical powder and molybdenum disilicide technology, which is applied in the field of composite powder materials, can solve the problems of anti-oxidation ablation coatings with many voids, roughness, and powders that are easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of molybdenum disilicide-coated tantalum boride-hafnium carbide spherical powder, comprising the following steps:

[0028] (1) mixing tantalum boride, hafnium carbide, polyvinyl alcohol and absolute ethanol for the first ball milling to obtain the first mixed slurry;

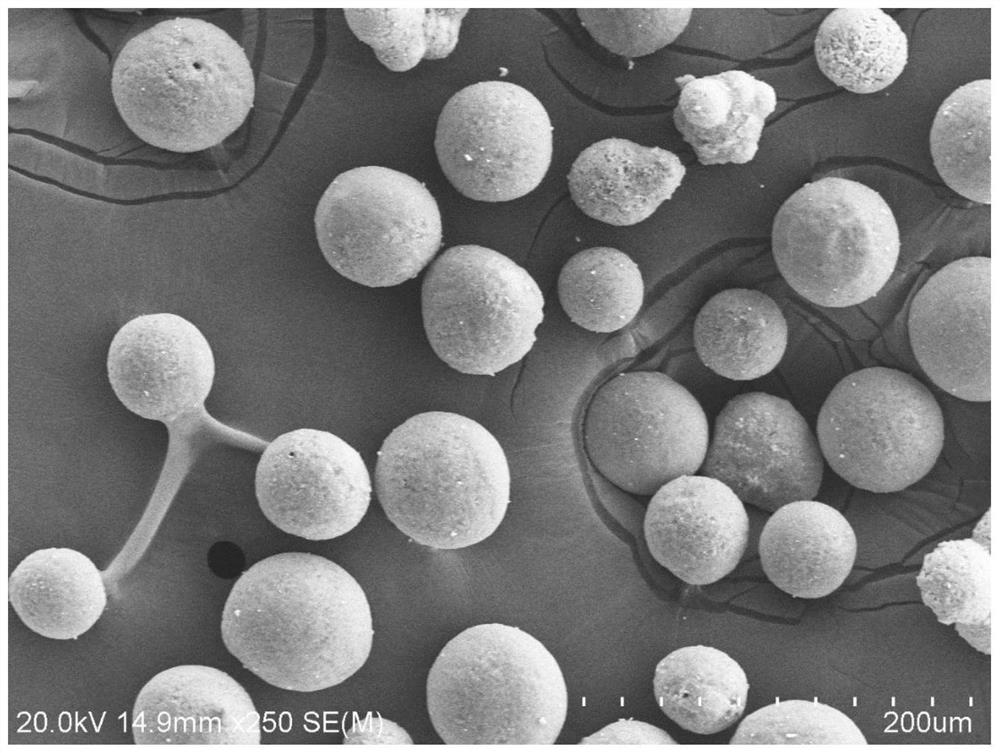

[0029] (2) performing the first spray drying and granulation on the first mixed slurry to obtain an agglomerated powder;

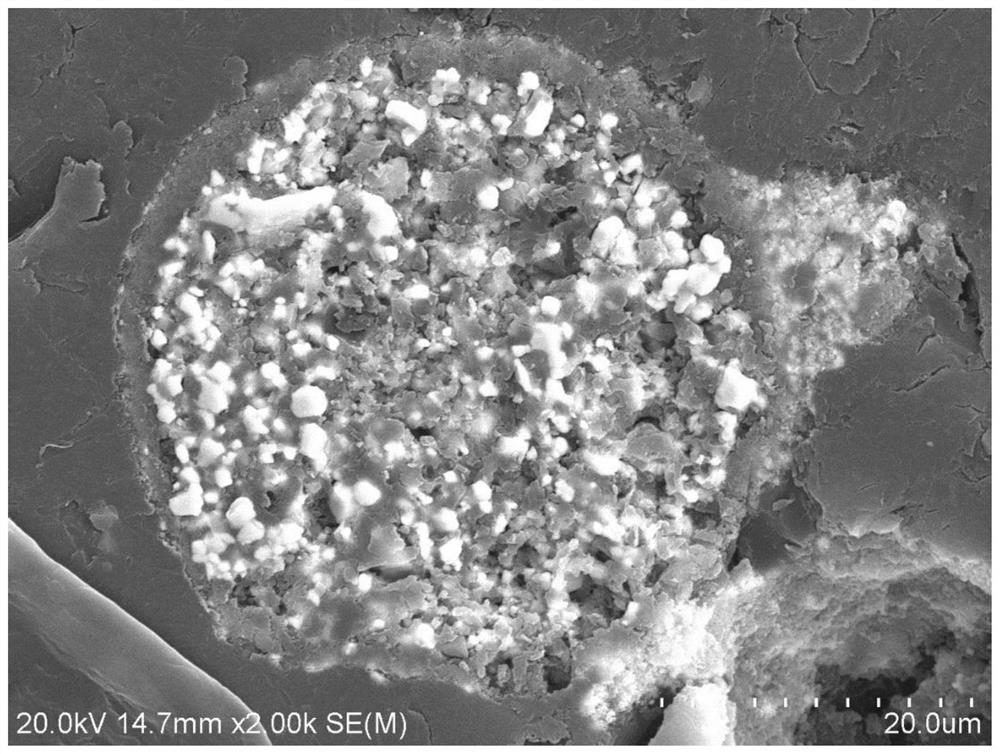

[0030] (3) The agglomerated powder is subjected to induction plasma spheroidization treatment sequentially to obtain a tantalum boride-hafnium carbide spherical powder;

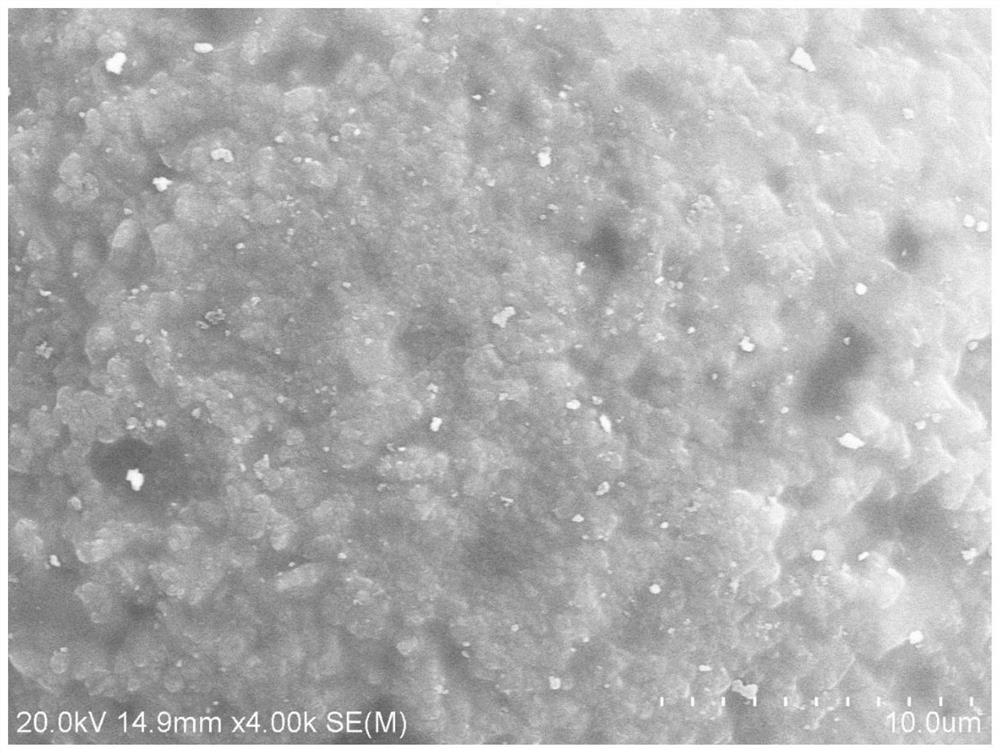

[0031] (4) mixing the tantalum boride-hafnium carbide spherical powder, molybdenum disilicide, water and polyvinyl alcohol for a second ball milling to obtain a second mixed slurry;

[0032] (5) The second mixed slurry is subjected to second spray-drying and granulation to obtain molybdenum disilicide-coated tantalum boride-hafnium carbide spherical powder.

[0033] In th...

Embodiment 1

[0049] (1) 65g of tantalum boride, 35g of hafnium carbide (the volume ratio of tantalum boride and hafnium carbide is 2.1:1), 1g of polyvinyl alcohol and 100g of absolute ethanol are prepared into a suspension, placed in a ball mill jar, and The material ratio is 4:1, and after ball milling for 3h at 250r / min, the first mixed slurry is obtained;

[0050] (2) Transfer the first mixed slurry obtained in step (1) to a spray drying granulation tower for agglomeration and granulation; wherein, the spray drying granulation parameters are: inlet temperature 210°C, outlet temperature 100°C, nozzle speed 25Hz , the speed of the peristaltic pump is 35rpm, the granulated powder is dried and passed through the inspection sieve to obtain BTa / HfC micron spherical agglomerated powder with a particle size of 20-100 μm, the drying temperature is 80°C, and the drying time is 24h.

[0051] (3) The agglomerated powder obtained in step (2) is sent to the induction plasma spheroidization equipment ...

Embodiment 2

[0058] (1) 65g of tantalum boride, 35g of hafnium carbide (the volume ratio of tantalum boride and hafnium carbide is 2.1:1), 3g of polyvinyl alcohol and 150g of absolute ethanol are prepared into a suspension, placed in a ball mill jar, and The material ratio is 4:1, and after ball milling at 100r / min for 6h, the first mixed slurry is obtained;

[0059] (2) Transfer the first mixed slurry obtained in step (1) to a spray drying granulation tower for agglomeration and granulation; wherein, the spray drying granulation parameters are: inlet temperature 300°C, outlet temperature 110°C, nozzle speed 29Hz , the speed of the peristaltic pump is 35rpm, the granulated powder is dried and passed through the inspection sieve to obtain BTa / HfC micron spherical agglomerated powder with a particle size of 20-100 μm, the drying temperature is 80°C, and the drying time is 24h.

[0060] (3) Send the agglomerated powder obtained in step (2) into an improved atmospheric plasma spray gun system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com