Carbon fiber enhanced hafnium boride-tantalum boride-carbon ceramic-based composite material and preparation method thereof

A composite material and carbon fiber preform technology, applied in the field of ceramic matrix composite materials, can solve the problem that the ceramic matrix composite materials cannot be modified by tantalum boride and hafnium boride at the same time, and the refractory tantalum boride and hafnium boride composite materials are evenly distributed and other problems, to achieve the effect of easy industrialization, outstanding mechanical properties, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

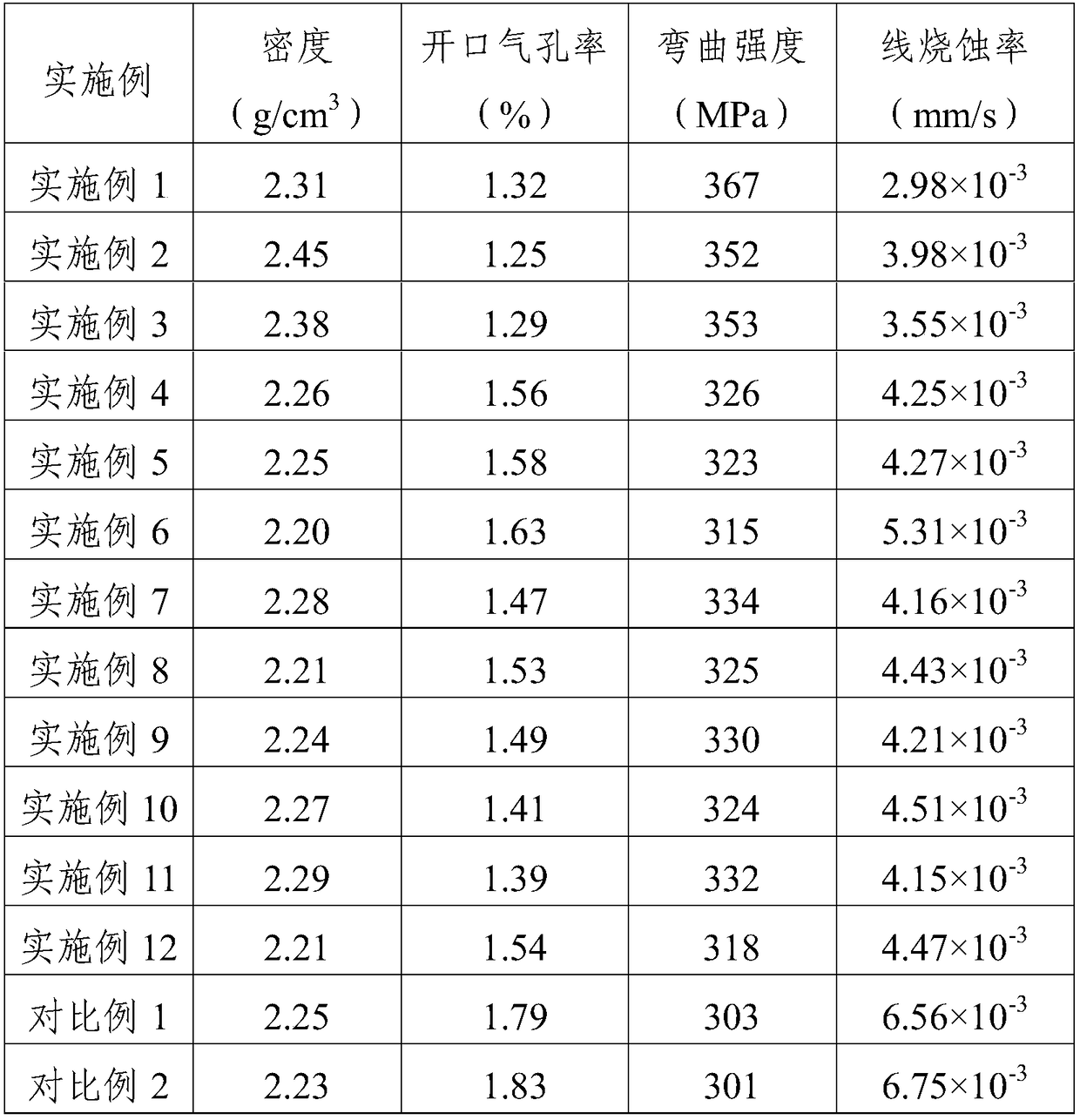

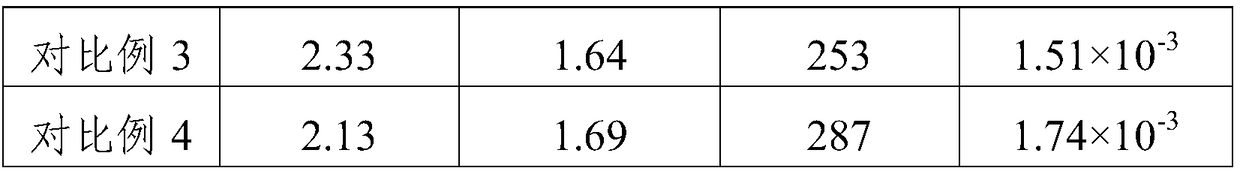

Examples

preparation example Construction

[0025] In a first aspect, the present invention provides a method for preparing a carbon fiber reinforced hafnium boride-tantalum boride-carbon ceramic matrix composite material, the method comprising the following steps:

[0026] (1) impregnating the carbon fiber preform with a hafnium-tantalum precursor solution containing a hafnium-tantalum precursor copolymer, a boron source precursor, a carbon source precursor and an organic solvent, and then curing and cracking the impregnated carbon fiber preform in sequence steps; and

[0027] (2) Step (1) is repeated several times to obtain a carbon fiber reinforced hafnium boride-tantalum boride-carbon ceramic matrix composite material.

[0028] In the present invention, the hafnium-tantalum precursor solution is, for example, obtained by dissolving a hafnium-tantalum precursor copolymer, a boron source precursor, and a carbon source precursor in an organic solvent, wherein the hafnium-tantalum precursor copolymer is used to provide ...

Embodiment 1

[0058] a C f / HfB 2 -TaB 2 -C composite material preparation method, using the impregnation cracking method of hafnium-tantalum precursor to prepare dense C f / HfB 2 -TaB 2 -C composite material, wherein the viscosity of the hafnium-tantalum precursor solution is 230mpa·s, and the solid content of the solution is 60%. The specific steps are:

[0059] ①The needle-punched carbon fiber braid was treated at a high temperature of 1700°C for 3 hours, and then deposited in a vapor deposition furnace for 60 hours, 120 hours, and 100 hours respectively to obtain a density of 1.03g / cm 3 carbon fiber preforms.

[0060] ②Impregnate the carbon fiber prefabricated body obtained in step ① under a vacuum of 0.05MPa for 1h (first pressure stage impregnation), then impregnate under 2MPa pressure for 1.5h (second pressure stage impregnation), and finally pressurize to 10MPa ( curing pressure), and heat up to 70°C for 1.5h (first temperature stage curing), 180°C for 1.5h (second temperature...

Embodiment 2

[0065] a C f / HfB 2 -TaB 2 -C composite material preparation method, using the impregnation cracking method of hafnium-tantalum precursor to prepare dense C f / HfB 2 -TaB 2 -C composite material, wherein the viscosity of the hafnium-tantalum precursor solution is 230mpa·s, and the solid content of the solution is 60%. The specific steps are:

[0066] ①The stitched carbon fiber braid was treated at a high temperature of 1700°C for 3 hours, and then deposited in a vapor deposition furnace for 100 hours, 120 hours, and 120 hours respectively, and the obtained density reached 1.18g / cm 3 carbon fiber preforms.

[0067] ②Impregnate the carbon fiber prefabricated body obtained in step ① under a vacuum of 0.05MPa for 1h, then under a pressure of 3MPa for 2h, and finally pressurize to 15MPa (curing pressure), and raise the temperature to 70°C for 2h, 180°C Keeping the temperature for 2 hours under 300° C. for 2 hours makes the precursor of hafnium and tantalum fully cross-linked an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com