Pipeline for LNG gasification pressure regulating measuring skid-mount package

A technology for metering skids and pipelines, which is applied in pipeline protection, pipeline anti-corrosion/rust protection, pipeline damage/wear prevention, etc. It can solve the problems of short service life, high maintenance cost, poor corrosion resistance and oxidation resistance of pipelines, etc. Achieve the effects of improving compatibility, increasing anti-aging and improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

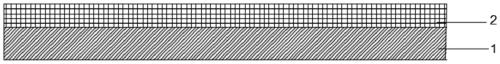

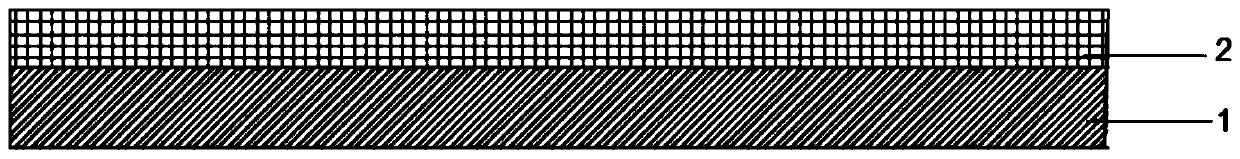

[0037] A pipeline for LNG gasification pressure regulation and metering prying, the pipeline includes a steel pipe and an anti-corrosion layer arranged on the steel pipe;

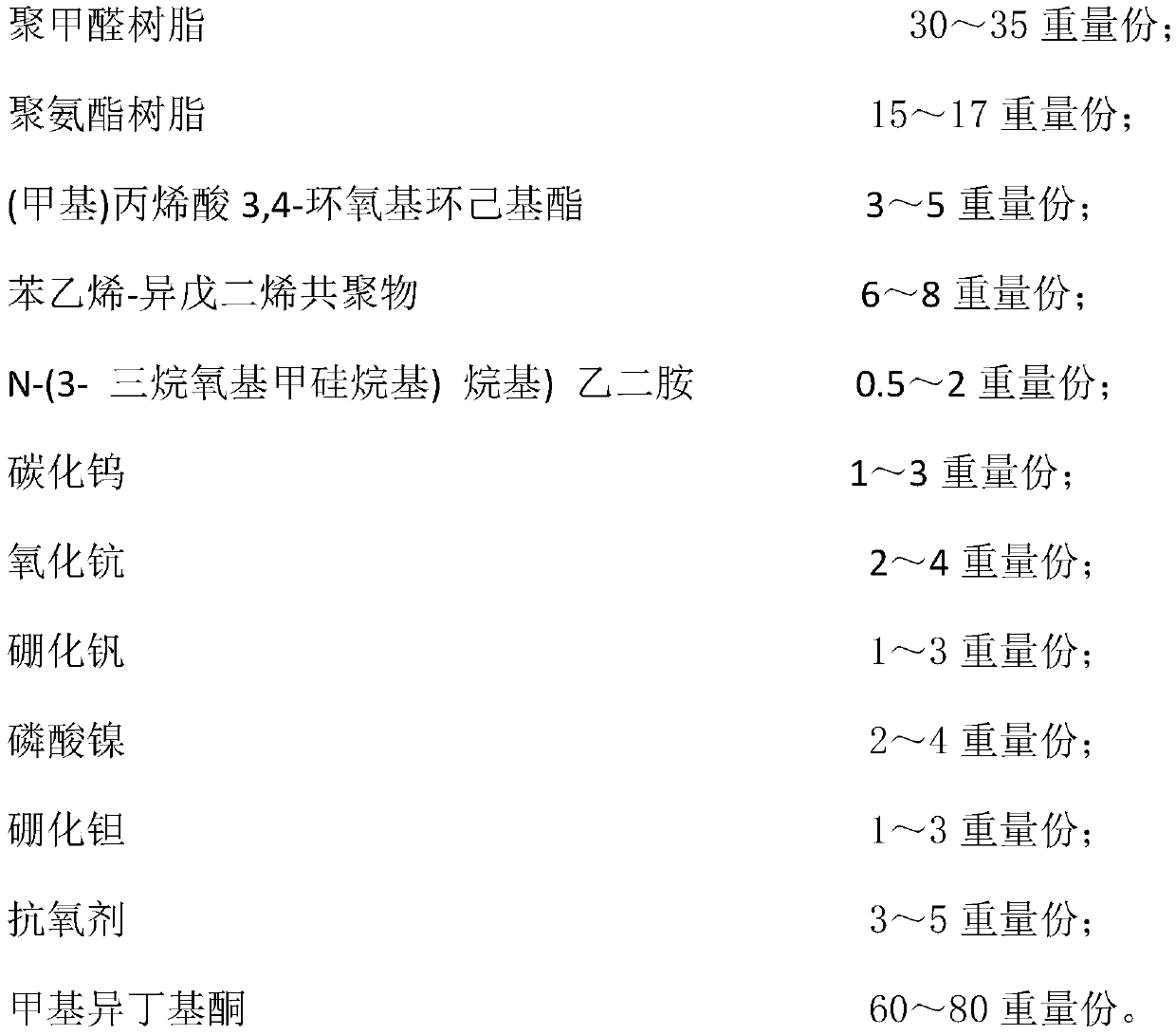

[0038] In parts by weight, the anti-corrosion layer includes the following components:

[0039]

[0040] The number average molecular weight of polyoxymethylene resin is 12000g / mol; the number average molecular weight of polyurethane resin is 8500g / mol; the number average molecular weight of styrene-isoprene copolymer is 4000g / mol; tungsten carbide, scandium oxide, vanadium boride The particle size of nickel phosphate and tantalum boride is 50nm;

[0041] Antioxidants include 35 wt% 4-methyl-1,3-dioxan-2-one, 25 wt% 2-mercaptobenzothiazole, 40 wt% 2,6-di-tert-butyl-4-methylphenol.

Embodiment 2

[0043] A pipeline for LNG gasification pressure regulation and metering prying, the pipeline includes a steel pipe and an anti-corrosion layer arranged on the steel pipe;

[0044] In parts by weight, the anti-corrosion layer includes the following components:

[0045]

[0046] The number average molecular weight of polyoxymethylene resin is 14000g / mol; the number average molecular weight of polyurethane resin is 8600g / mol; the number average molecular weight of styrene-isoprene copolymer is 4500g / mol; tungsten carbide, scandium oxide, vanadium boride The particle size of nickel phosphate and tantalum boride is 60nm; antioxidants include 37wt% 4-methyl-1,3-dioxan-2-one, 22wt% 2-mercaptobenzothiazole, 41wt% 2, 6-di-tert-butyl-4-methylphenol.

Embodiment 3

[0048] A pipeline for LNG gasification pressure regulation and metering prying, the pipeline includes a steel pipe and an anti-corrosion layer arranged on the steel pipe;

[0049] In parts by weight, the anti-corrosion layer includes the following components:

[0050]

[0051] The number average molecular weight of polyoxymethylene resin is 16000g / mol; the number average molecular weight of polyurethane resin is 9000g / mol; the number average molecular weight of styrene-isoprene copolymer is 5000g / mol; tungsten carbide, scandium oxide, vanadium boride The particle size of nickel phosphate and tantalum boride is 70nm; antioxidants include 40wt% 4-methyl-1,3-dioxane-2-one, 20wt% 2-mercaptobenzothiazole, 40wt% 2, 6-di-tert-butyl-4-methylphenol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com