A corrosion resistant object having an outer layer of a ceramic material

A technology of ceramic materials and objects, applied in the direction of metal material coating process, coating, electrical components, etc., can solve the problems of high cost and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

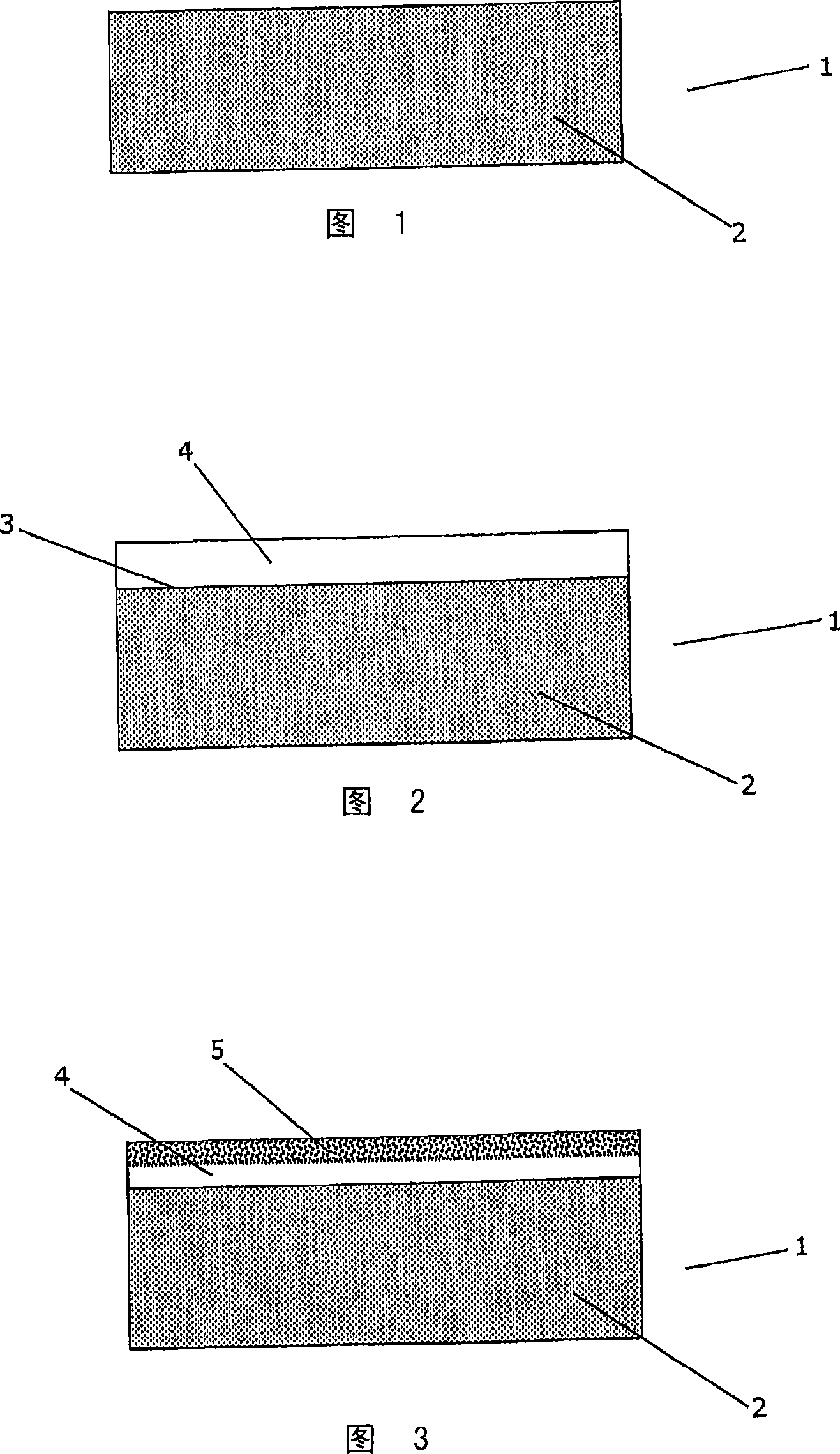

[0043] Figure 1 shows an object 1 according to an embodiment of the invention. The object 1 comprises an electrically conductive body part 2, eg made of or comprising copper or silver.

[0044] FIG. 2 shows the item 1 of FIG. 1 . In Fig. 2, the outer surface 3 of the body part 2 has been provided with a coating 4 comprising a refractory metal, preferably tantalum. The layer 4 is applied in order to improve the corrosion resistance properties of the object 1 .

[0045] FIG. 3 shows the item 1 of FIGS. 1 and 2 . In Fig. 3, the object 1 has been processed in such a way that the outer part 5 of the refractory metal layer 4 has been converted into a conductive ceramic material. The ceramic material 5 may advantageously be tantalum boride, such as TaB 2 . The ceramic material 5 prevents oxidation of the refractory metal layer 4 and thus prevents passivation of the object 1 .

[0046] Figures 1-3 thus illustrate a method of forming an object 1 according to an embodiment of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com