Catalyst chemical vapor deposition apparatus

A chemical vapor growth, catalyst technology, applied in physical/chemical process catalysts, gaseous chemical plating, liquid chemical plating and other directions, can solve the problems of low mechanical strength, unassisted production efficiency, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

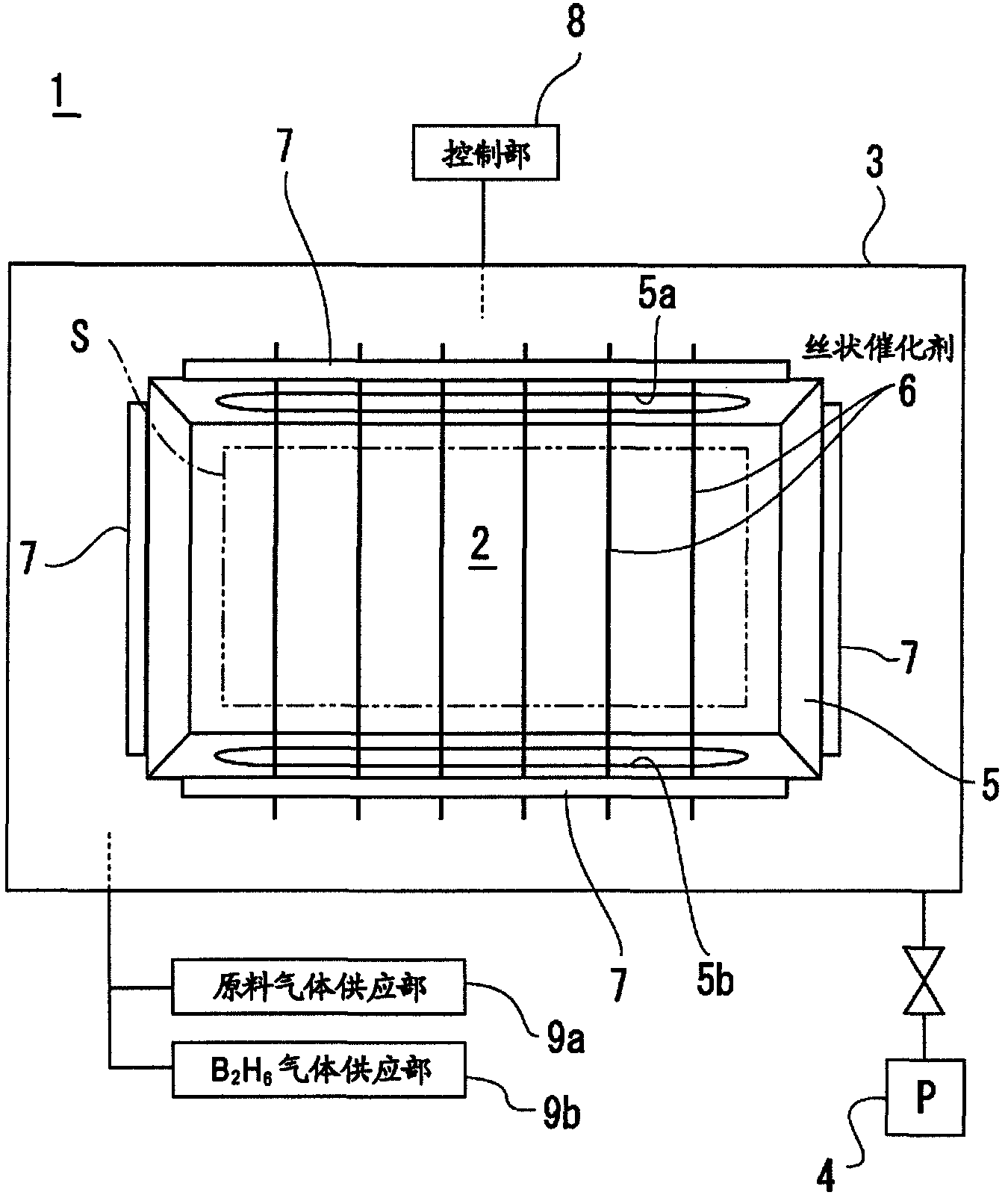

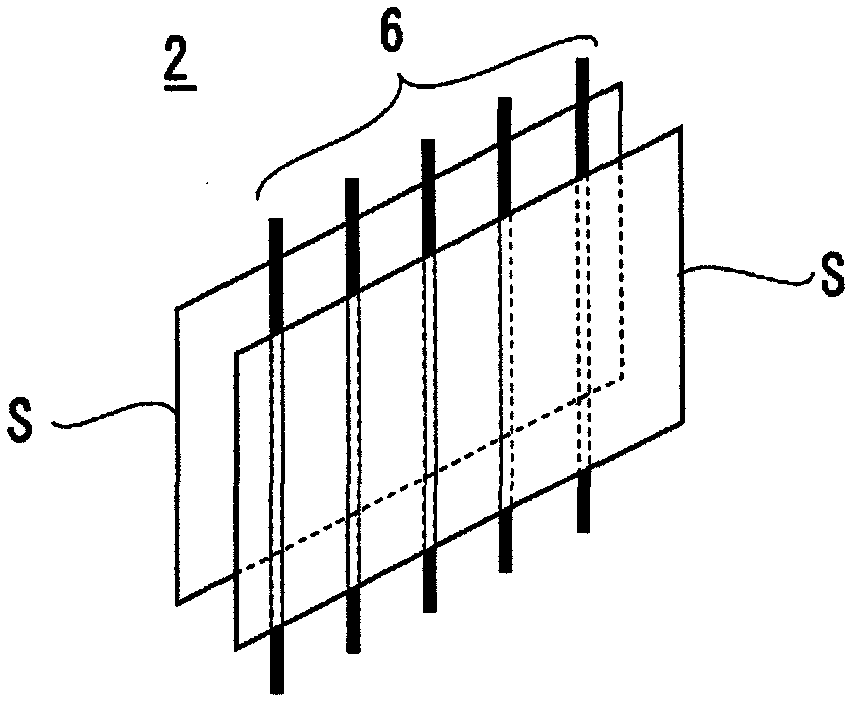

[0040] Next, the catalyst-assisted chemical vapor growth method in the second embodiment of the present invention will be described.

[0041] Inside the reaction chamber 2 are provided a substrate S and a tantalum wire as a wire catalyst 6 . Then, the vacuum pump 4 is operated to exhaust the gas inside the vacuum chamber 3 and make it into a vacuum state. At this time, the inside of the reaction chamber 2 can be decompressed to a predetermined vacuum degree (for example, 1 Pa). Next, the raw material gas and diborane gas are introduced into the reaction chamber 2 from the raw material gas supply part 9a and the diborane gas supply part 9b through the gas introduction pipe 7, and the filament catalysts 6 are energized by the control part 8 to turn them Heating to a temperature above the specified value (for example, 1700°C).

[0042] The diborane gas introduced into the reaction chamber 2 contacts and decomposes the filament catalyst 6 , thereby forming a boride (tantalum bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com