Environmentally friendly inflaming retarding type PVC cable material and preparation method thereof

A polyvinyl chloride cable, polyvinyl chloride technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., to achieve the effects of excellent heat resistance, low production cost, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

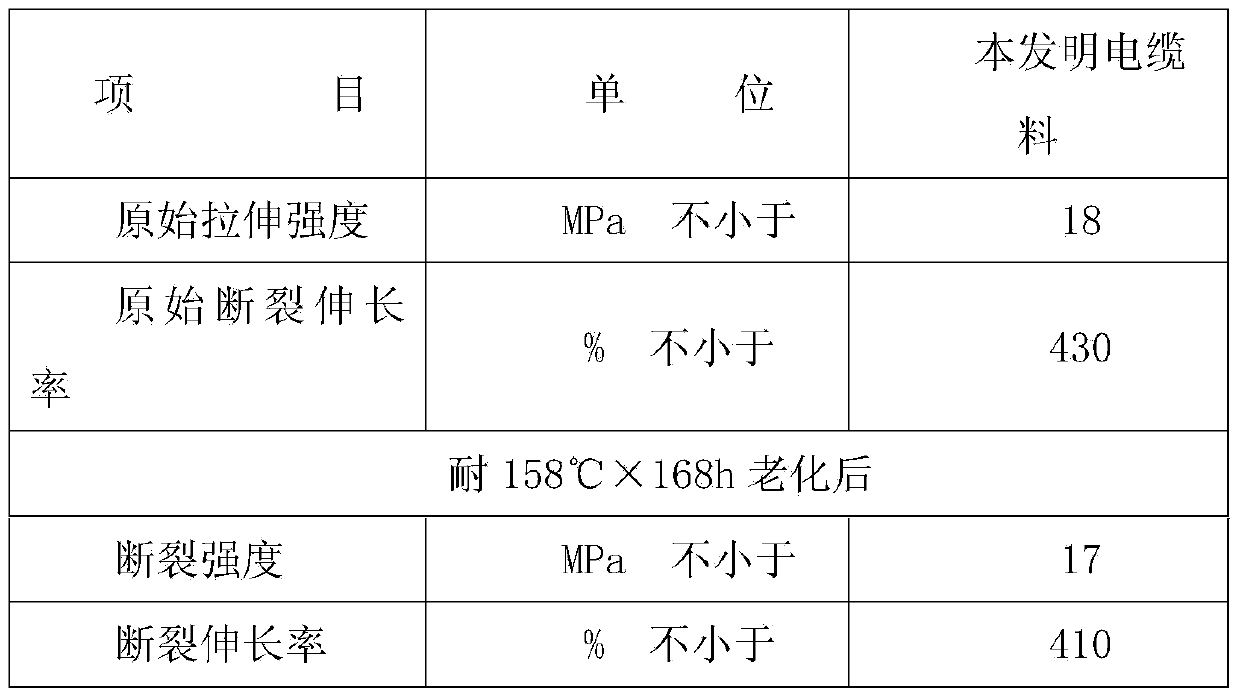

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

[0014] An environmentally friendly flame-retardant polyvinyl chloride cable material, made of the following raw materials in parts by weight (kg): polyvinyl chloride 34, chlorinated paraffin 5, epoxy soybean oil 4, antimony trioxide 5, aluminum hydroxide 12 , zinc borate 4, polyphenylene sulfide 12, poly-4-methyl-1-pentene 4, bentonite 12, tantalum boride 3, p-tert-butylbenzoic acid 1, magnesium oxide 10, microcrystalline wax 5 , antioxidant 10101, additive 6;

[0015] The auxiliary agent is made of the following raw materials in parts by weight (kg): sepiolite powder 12, dimethylaminoethyl acrylate 4, urotropine 1, sodium tripolyphosphate 2, SnO 2 1, silicon carbide powder 2, crosslinking agent TAC1, magnesium oxide 2, straw ash 1, aluminum stearate 1, tributyl citrate 1, wintergreen oil 0.1; the preparation method is to send sepiolite powder into a calciner Calcined at 700-730°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com