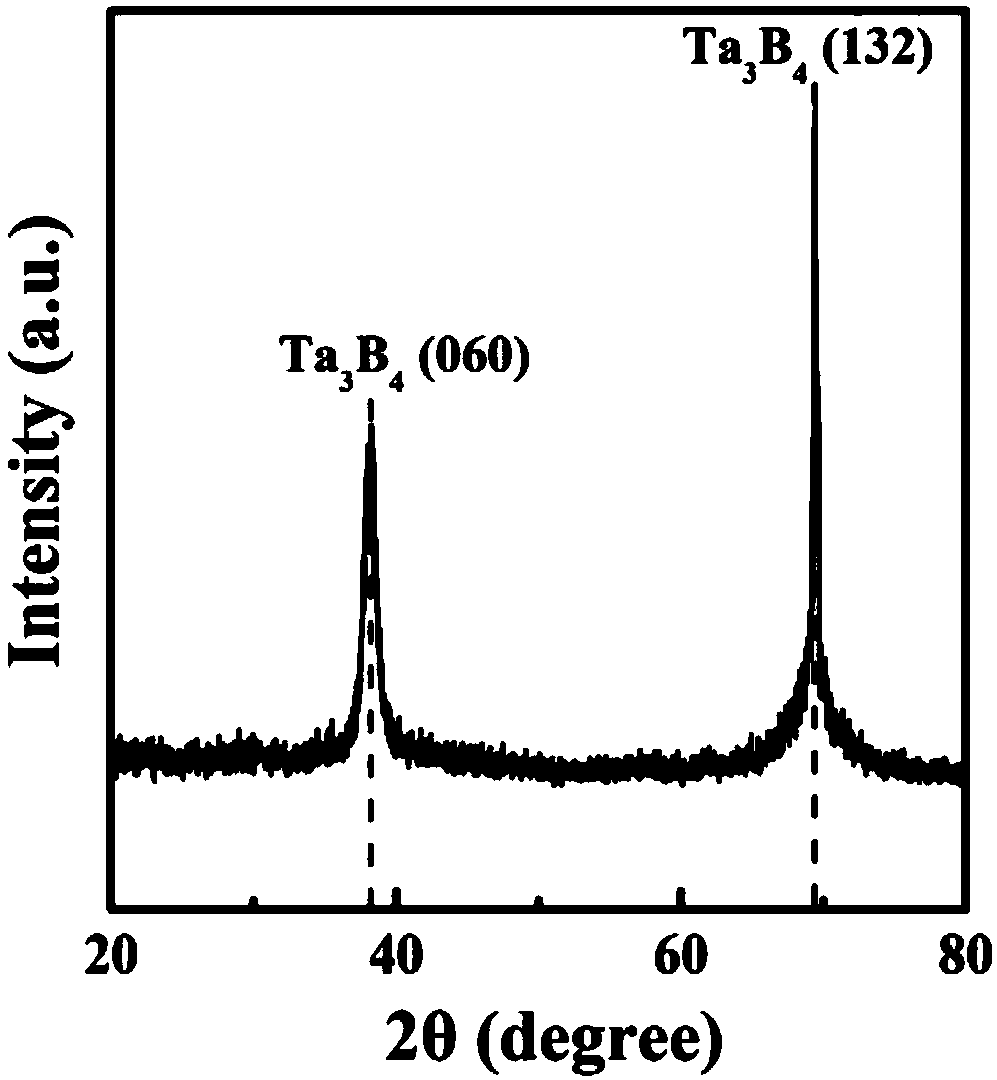

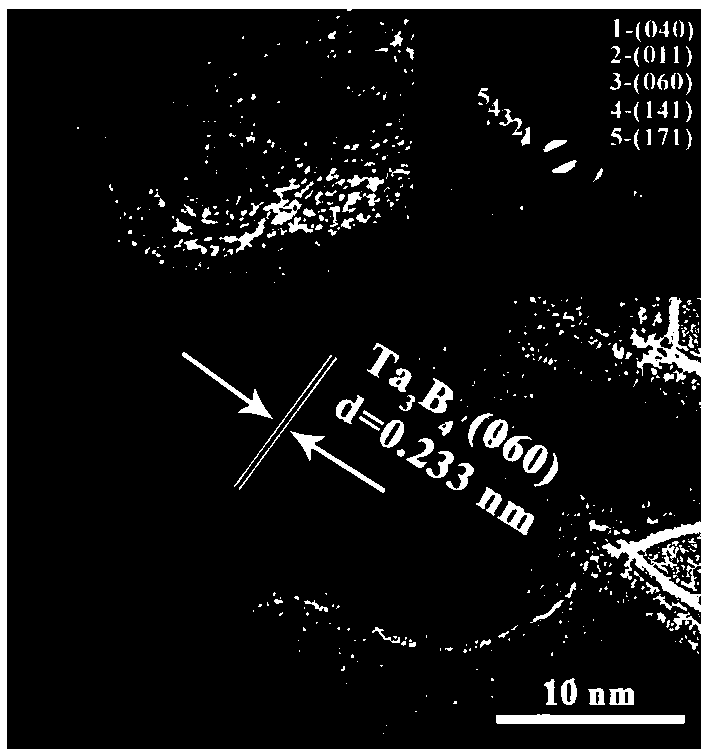

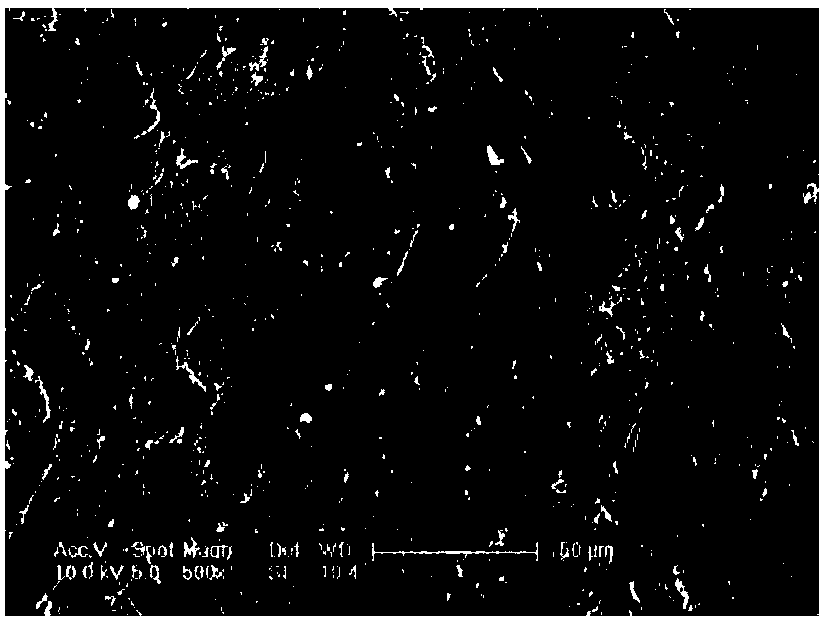

Tantalum boride bio-coating, and production method and application thereof

A bio-coating, tantalum boride technology, applied in coating, metal material coating process, ion implantation plating, etc. Good biological activity, reducing the effect of precipitation of toxic elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The biomedical titanium alloy (Ti6Al4V) with a diameter of 10 mm and a thickness of 1 mm was polished step by step by 400 mesh, 800 mesh and 1200 mesh silicon carbide sandpaper. Use acetone, absolute ethanol and deionized water to clean ultrasonically for 15 minutes, and blow dry with nitrogen;

[0029] Install the medical titanium alloy substrate obtained by the above cleaning on the sample stage, and install the tantalum target and the boron target on the target stage respectively; adjust the distance between the target and the substrate to be 8cm; turn on the mechanical pump and the molecular pump successively Vacuum, the vacuum degree reaches 4×10 -4 Below Pa; pass in pure argon, and pre-sputter the target for 15 minutes;

[0030] Set the power of the tantalum target to 30W, the power of the boron target to 250W, the base distance of the target to 6cm, the total sputtering pressure to 1.0Pa, the deposition temperature to room temperature, and the voltage applied to...

Embodiment 2

[0033] The biomedical titanium alloy (Ti6Al4V) with a diameter of 10 mm and a thickness of 1 mm was polished step by step by 400 mesh, 800 mesh and 1200 mesh silicon carbide sandpaper. Use acetone, absolute ethanol and deionized water to clean ultrasonically for 15 minutes, and blow dry with nitrogen;

[0034] Install the medical titanium alloy substrate obtained by the above cleaning on the sample stage, and install the tantalum target and the boron target on the target stage respectively; adjust the distance between the target and the substrate to 10cm; turn on the mechanical pump and the molecular pump successively Vacuum, the vacuum degree reaches 4×10 -4 Below Pa; pass in pure argon, and pre-sputter the target for 15 minutes;

[0035] The power of the tantalum target is set to 60W, the power of the boron target is set to 300W, the target base distance is 10cm, the total sputtering pressure is 1.0Pa, the deposition temperature is room temperature, and the voltage applied ...

Embodiment 3

[0038]The biomedical titanium alloy (Ti6Al4V) with a diameter of 10 mm and a thickness of 1 mm was polished step by step by 400 mesh, 800 mesh and 1200 mesh silicon carbide sandpaper. Use acetone, absolute ethanol and deionized water to clean ultrasonically for 15 minutes, and blow dry with nitrogen;

[0039] Install the medical titanium alloy substrate obtained by the above cleaning on the sample stage, and install the tantalum target and the boron target on the target stage respectively; adjust the distance between the target and the substrate to 9cm; turn on the mechanical pump and the molecular pump successively Vacuum, the vacuum degree reaches 4×10 -4 Below Pa; pass pure argon gas, and pre-sputter the target for 10 minutes; to remove the impurity atoms adsorbed on the target.

[0040] Set the power of the tantalum target to 45W, the power of the boron target to 350W, the target base distance to 9cm, the total sputtering pressure to 0.8Pa, the deposition temperature to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Coating hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com