Method for preparing Ge-Sb-Te ternary phase-change material film

A technology of ge-sb-te and material thin film, which is applied in the direction of electrolytic inorganic material coating, static memory, instrument, etc., can solve the problem of high preparation cost and ionic solution system 1-butyl-3-methylimidazolium hexafluorophosphate Complicated, difficult process and other problems, to achieve the effect of stable product quality, low cost, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

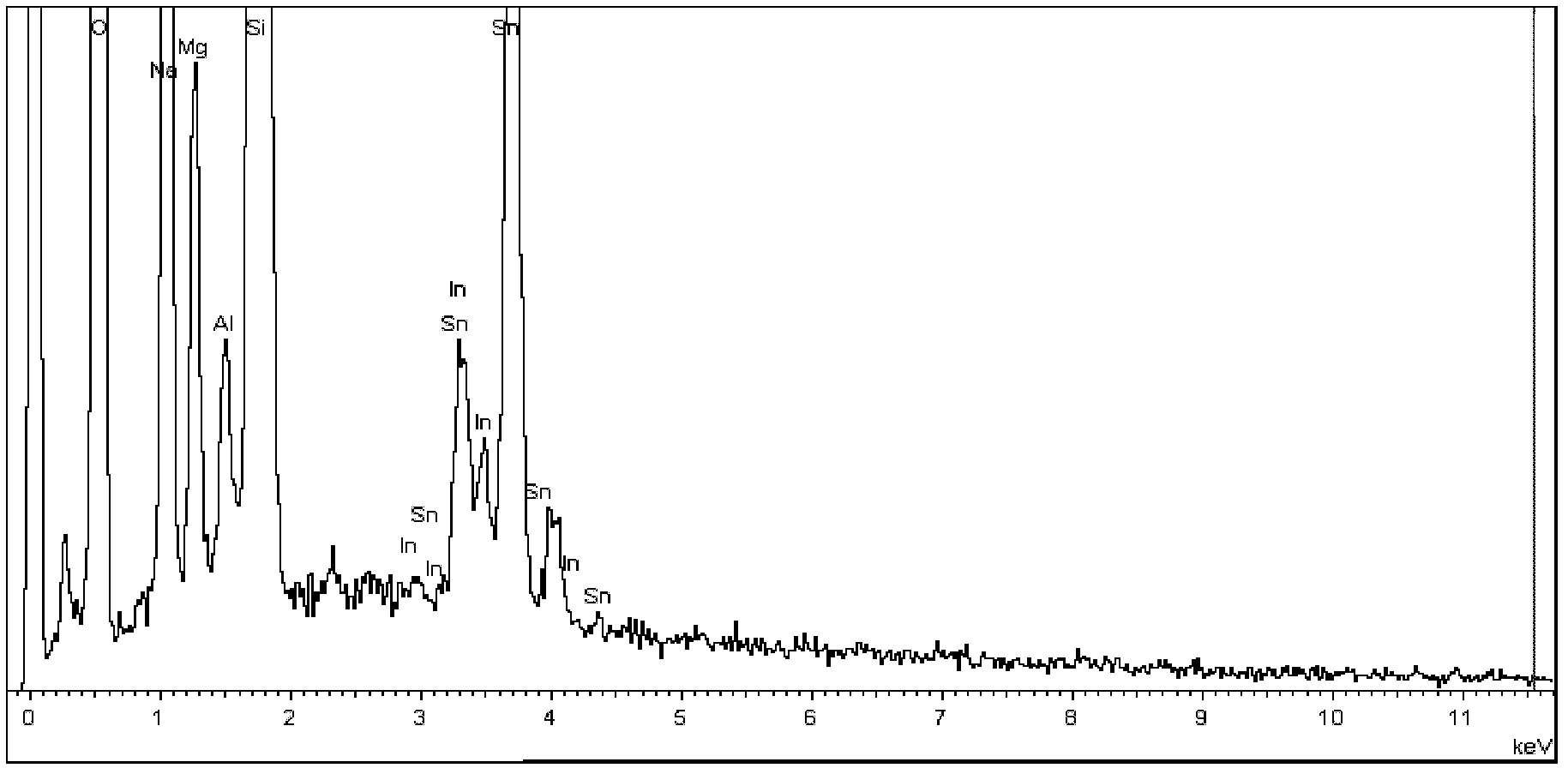

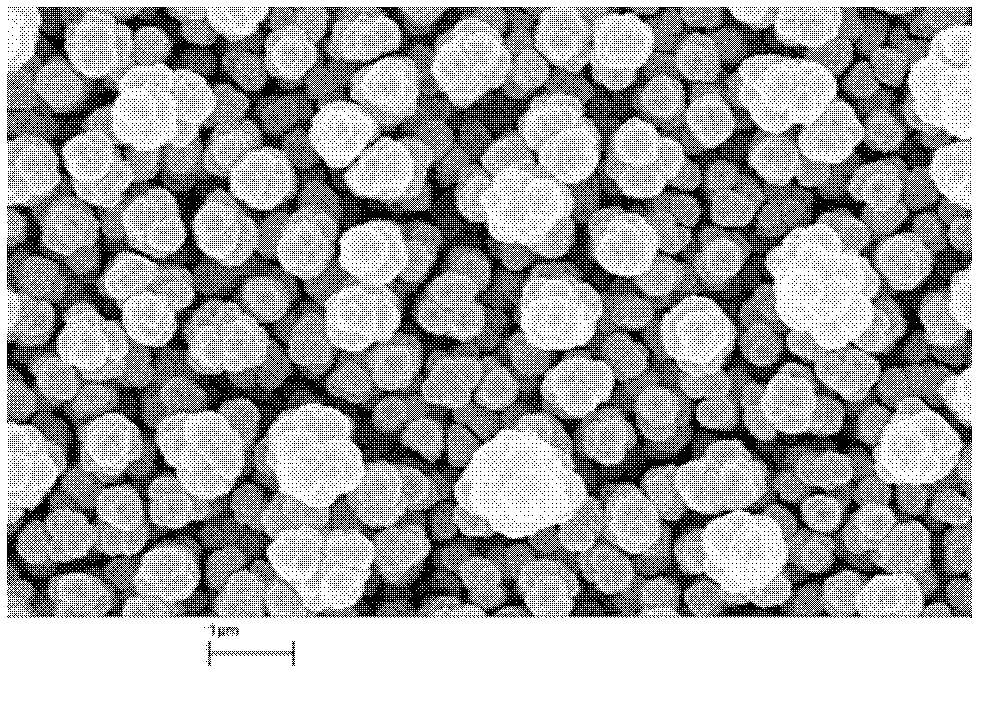

[0035] After the ITO conductive glass substrate was cut and polished, it was ultrasonically cleaned with acetone, absolute ethanol, and ultrapure water for 1 hour, and dried to obtain a working electrode with a clean surface and no foreign matter. Using tellurium dioxide (TeO) with a purity of 99.99% 2 ) 1.596g and antimony trioxide (Sb 2 o 3 )0.583g and 1mol / L of H 2 SO 4 Solution 100ml to prepare 1L Sb 3+ and Te 4+ Ionic electrolyte solution, add 28.4g of Na in the electrolyte solution 2 SO 4 As a supporting electrolyte, 45g of tartaric acid as a co-solvent, Sb 3+ and Te 4+ The concentrations are 4mmol / L and 10mmol / L respectively, using H 2 SO 4 solution and NaOH solution adjusted so that Sb 3+ and Te 4+ The pH of the ionic electrolyte solution is 1.6. Before deposition, the solution was left to stand for 1 hour to ensure that no precipitation occurred, and nitrogen gas was passed for 10 minutes to remove dissolved oxygen in the water. The constant potential el...

Embodiment 2

[0038] After the ITO conductive glass substrate was cut and polished, it was ultrasonically cleaned with acetone, absolute ethanol, and ultrapure water for 1 hour, and dried to obtain a working electrode with a clean surface and no foreign matter. Using tellurium dioxide (TeO) with a purity of 99.99% 2 ) 1.596g and antimony trioxide (Sb 2 o 3 )0.583g and 1mol / L of H 2 SO 4 Solution 100ml to prepare 1L Sb 3+ and Te 4+ Ionic electrolyte solution, add 28.4g of Na in the electrolyte solution 2 SO 4 As a supporting electrolyte, 45g of tartaric acid as a co-solvent, Sb 3+ and Te 4+ The concentrations are 4mmol / L and 10mmol / L respectively, using H 2 SO 4 solution and NaOH solution adjusted so that Sb 3+ and Te 4+ The pH of the ionic electrolyte solution is 1.6. Before deposition, the solution was left to stand for 1 hour to ensure that no precipitation occurred, and nitrogen gas was passed for 10 minutes to remove dissolved oxygen in the water. The constant potential el...

Embodiment 3

[0041] After the ITO conductive glass substrate was cut and polished, it was ultrasonically cleaned with acetone, absolute ethanol, and ultrapure water for 1 hour, and dried to obtain a working electrode with a clean surface and no foreign matter. Using tellurium dioxide (TeO) with a purity of 99.99% 2 ) 1.596g and antimony trioxide (Sb 2 o 3 )0.583g and 1mol / L of H 2 SO 4 Solution 100ml to prepare 1L Sb 3+ and Te 4+ Ionic electrolyte solution, add 28.4g of Na in the electrolyte solution 2 SO 4 As a supporting electrolyte, 45g of tartaric acid as a co-solvent, Sb 3+ and Te 4+ The concentrations are 4mmol / L and 10mmol / L respectively, using H 2 SO 4 solution and NaOH solution adjusted so that Sb 3+ and Te4+ The pH of the ionic electrolyte solution is 1.6. Before deposition, the solution was left to stand for 1 hour to ensure that no precipitation occurred, and nitrogen gas was passed for 10 minutes to remove dissolved oxygen in the water. The constant potential elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com