Quasicrystal intermediate alloy containing Mg-Zn-Gd radical and preparation method thereof

A master alloy, mg-39wt.%gd technology, applied in the field of high-content quasi-crystal master alloy and its preparation, can solve the problems of looseness and unsuitability for the use of structural materials, and achieve an increase in the use temperature range, high corrosion resistance, and improved Effects of multiple mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

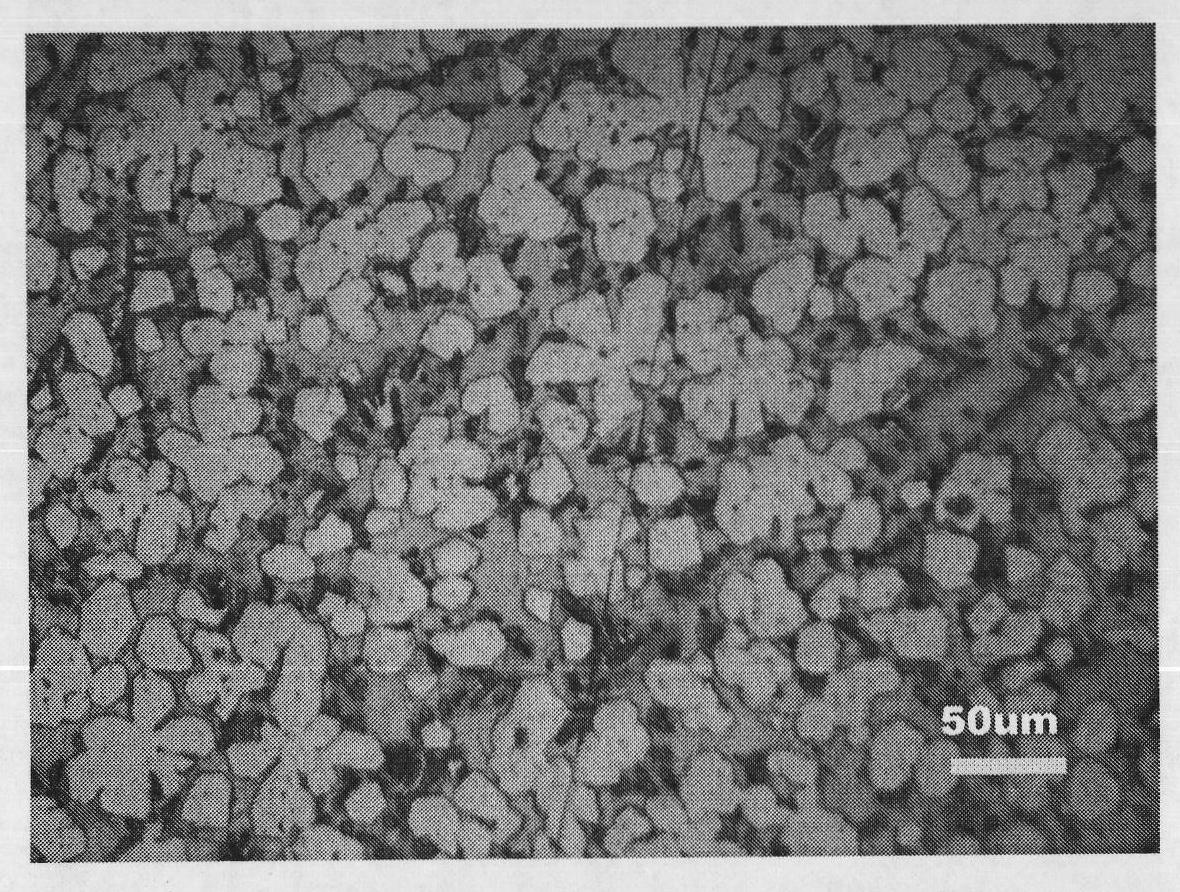

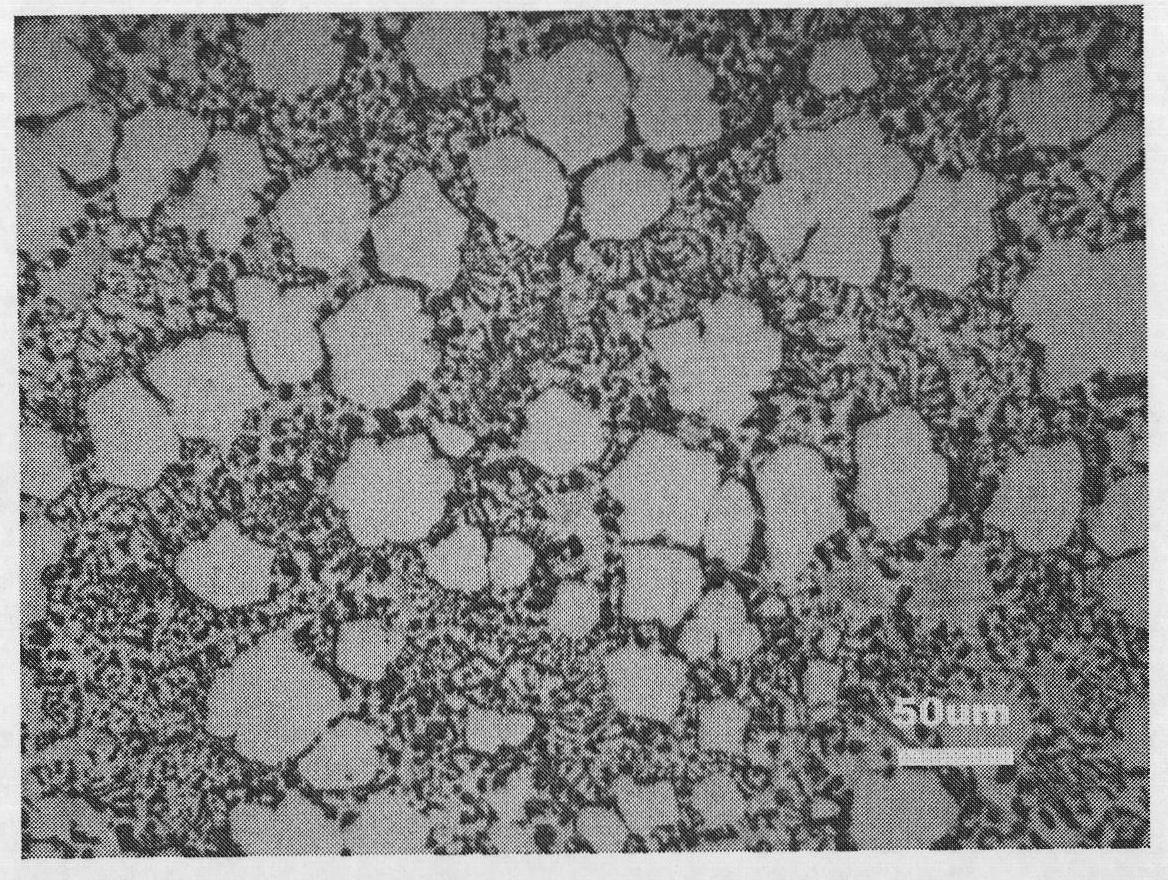

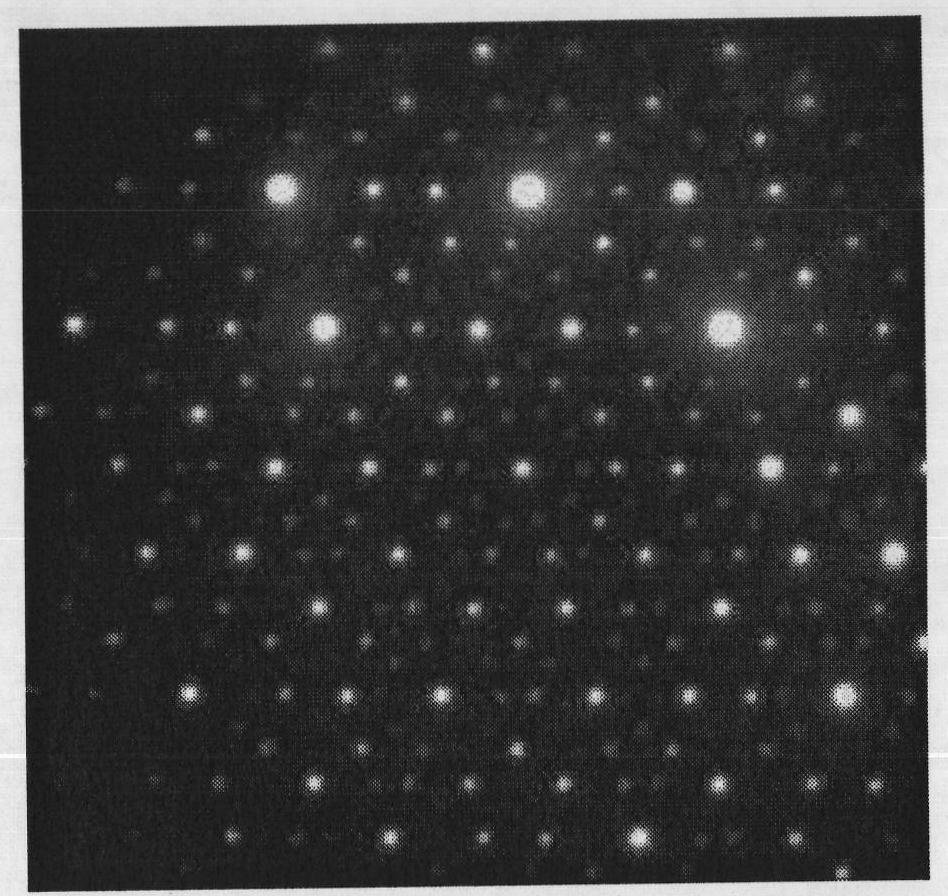

Image

Examples

Embodiment 1

[0021]I. The test raw materials are 181 grams of pure Mg (99.9wt.%) (calculated by 20% burning loss), 624 grams of pure Zn (99.99wt.%) (calculated by 20% burning loss), and Mg-39wt.% 410 grams of Gd master alloy (calculated on the basis of 30% burning loss);

[0022] II. Firstly dry the raw material ingot at 200°C, then clean the surface with a steel brush to remove surface oxides to reduce the generation of smelting impurities, and dry the smelting tools such as molds and crucibles in an oven at 200°C;

[0023] III. The smelting sequence of raw materials is Mg ingot, pure Zn, Mg-39wt.%Gd master alloy, and SF is used in the smelting process 6 +N 2 Mixed gas is used for protection to prevent oxidation and burning, and the composition of the protective gas is SF 6 (1vol.%)+N 2 (99vol.%). Put the preheated ingot into the crucible, put it into the well-type resistance furnace, and melt it under the protection of gas, and the melting temperature is 750°C;

[0024] IV. After th...

Embodiment 2

[0027] I. The test raw materials are 258 grams of pure Mg (99.9wt.%) (calculated by 20% burning loss), 512 grams of pure Zn (99.99wt.%) (calculated by 20% burning loss), and Mg-39wt.% 440 grams of Gd master alloy (calculated on the basis of 30% burning loss);

[0028] II. Firstly dry the raw material ingot at 200°C, then clean the surface with a steel brush to remove surface oxides to reduce the generation of smelting impurities, and dry the smelting tools such as molds and crucibles in an oven at 200°C;

[0029] III. The smelting sequence of raw materials is Mg ingot, pure Zn, Mg-39wt.%Gd master alloy, and SF is used in the smelting process 6 +N 2 Mixed gas is used for protection to prevent oxidation and burning, and the composition of the protective gas is SF 6 (1vol.%)+N 2 (99vol.%). Put the preheated ingot into the crucible, put it into the well-type resistance furnace, and melt it under the protection of gas, and the melting temperature is 750°C;

[0030] IV. After t...

Embodiment 3

[0033] I. The test raw materials are 78 grams of pure Mg (99.9wt.%) (calculated by 20% burning loss), 744 grams of pure Zn (99.99wt.%) (calculated by 20% burning loss), and Mg-39wt.% 390 grams of Gd master alloy (calculated on the basis of 30% burning loss);

[0034] II. First dry the raw material ingot at 200°C, and then clean the surface with a steel brush to remove surface oxides to reduce the generation of smelting impurities. Melting tools such as molds and crucibles are dried in an oven at 200°C;

[0035] III. The smelting sequence of raw materials is Mg ingot, pure Zn, Mg-39wt.%Gd master alloy, and SF is used in the smelting process 6 +N 2 Mixed gas is used for protection to prevent oxidation and burning, and the composition of the protective gas is SF 6 (1vol.%)+N 2 (99vol.%). Put the preheated ingot into the crucible, put it into the well-type resistance furnace, and melt it under the protection of gas, and the melting temperature is 740°C;

[0036] IV. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com