Al-Ti-C-Er refiner and preparation method

A technology of al-ti-c-er and refiner, which is applied in the field of rare earth refiner and preparation of aluminum alloy, can solve the problem of limiting the wide application of Al-Ti-C grain refiner, increasing the preparation cost, wetting It can improve the morphology and distribution, improve the refining efficiency, and improve the wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

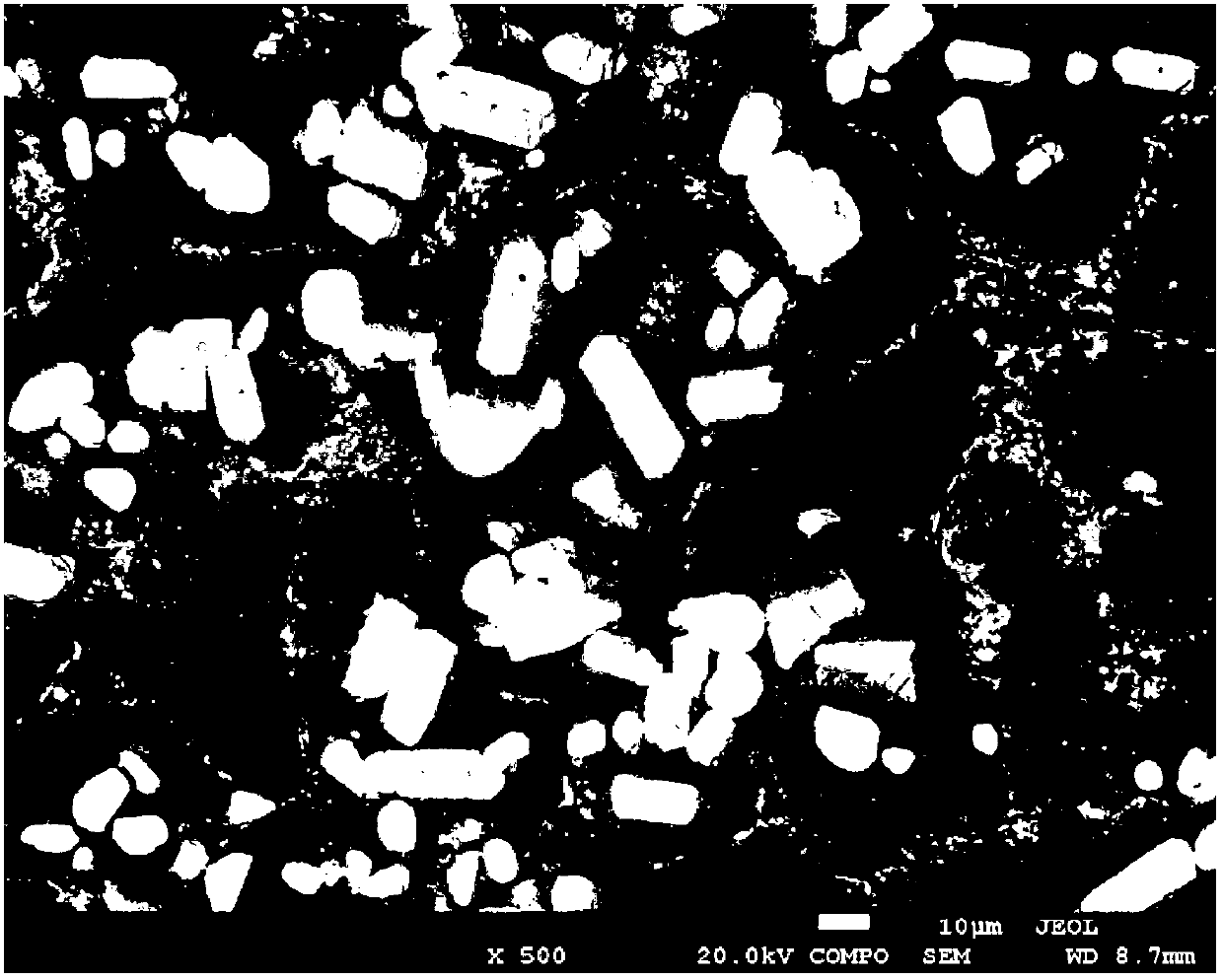

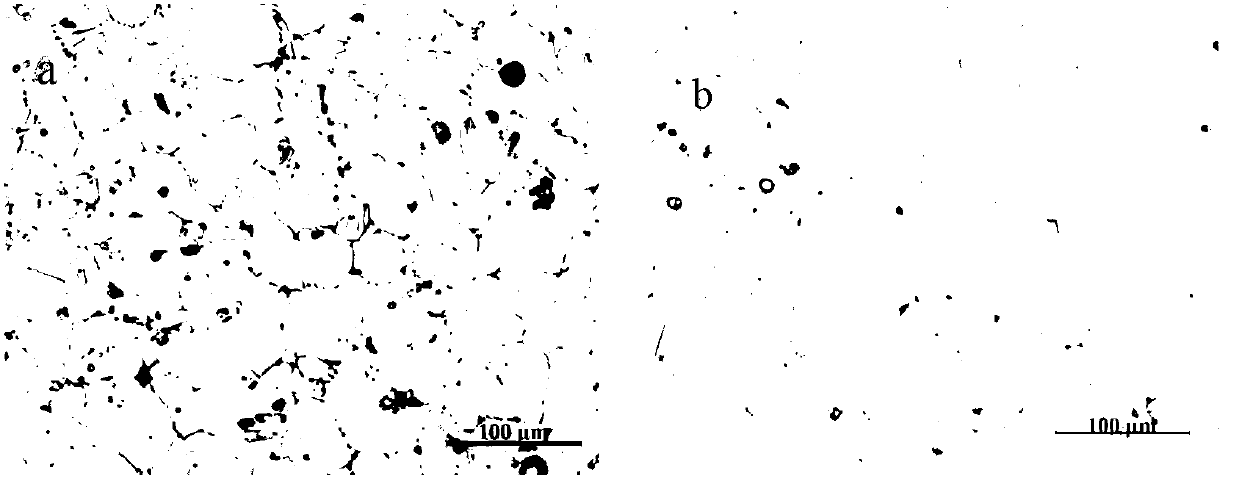

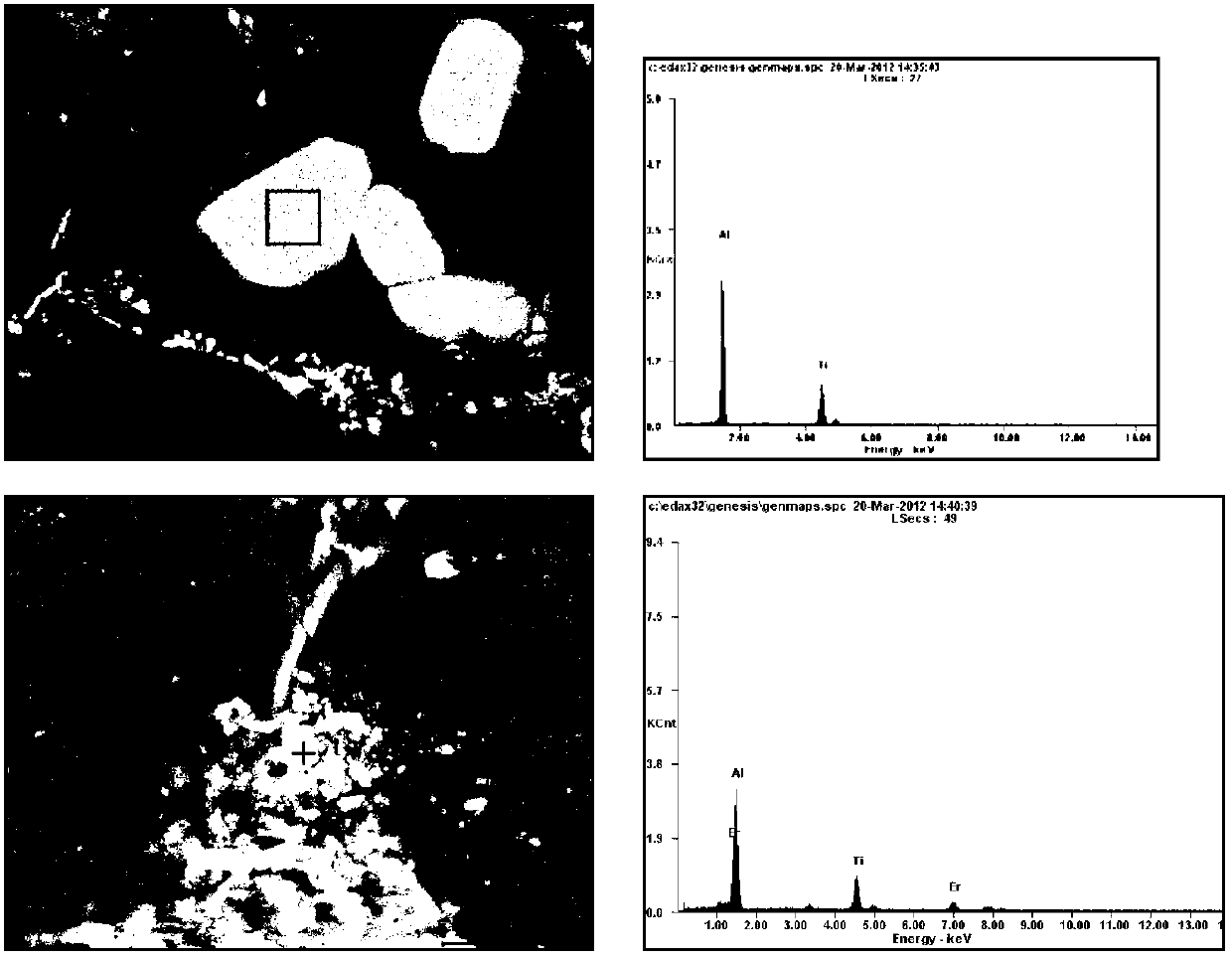

[0019] The process of preparing Al-5Ti-0.3C-0.2Er refiner by self-propagating reaction method is as follows:

[0020] 1. Raw material preparation, refiner consists of aluminum ingot, aluminum powder, titanium powder, graphite powder, Al-Er master alloy, C 2 Cl 6 and cryolite covering agent preparation. Among them, the purity of aluminum ingot is 99.9%, the powder particle size is 325 mesh for Ti powder, and 300 mesh for C powder.

[0021] 2. Prepare 1Kg of refiner, weigh graphite powder, titanium powder, aluminum powder, Al-Er master alloy, and aluminum ingot as required, and the aluminum burning loss rate is 3%. It is required that Ti / C=50 / 3 (wt%); the powder accounts for 60% of the mass of the powder block (the mass of aluminum powder is 78g).

[0022] 3. Mix titanium powder, aluminum powder and graphite powder evenly, place the mixed powder in a mold, apply a pressure of 10MPa, and press it into a cylindrical powder block of φ40×50.

[0023] 4. Cryolite and C 2 Cl 6 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com