Masking mechanism for film-forming device

a film-forming device and masking mechanism technology, applied in the field of masking mechanism or device for film-forming apparatus, can solve the problems of large amount of time, reproducible data, or no longer reliable data, and the number of masks that can be mounted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the present invention will be described in detail with reference to certain suitable forms of implementation thereof illustrated in the drawing figures.

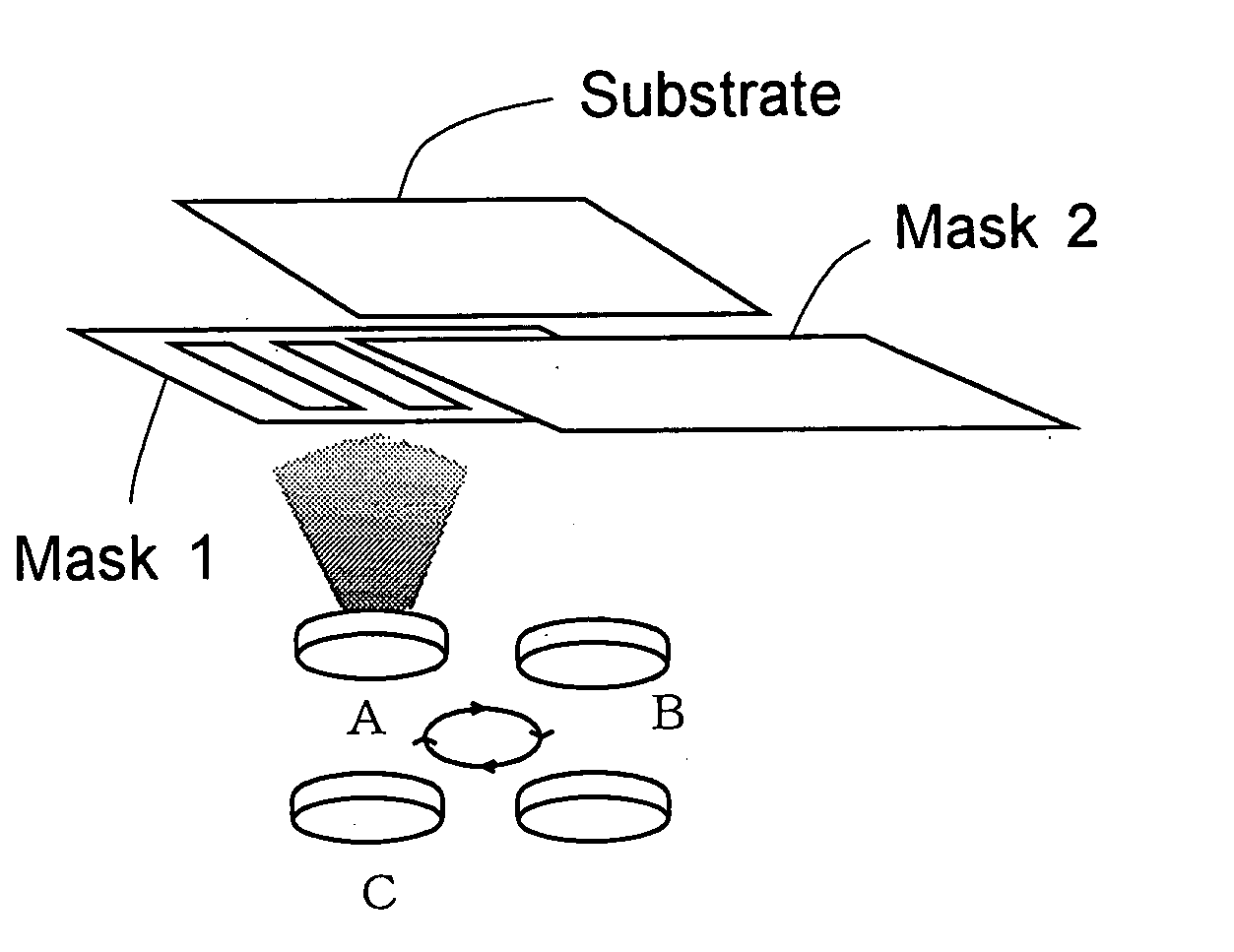

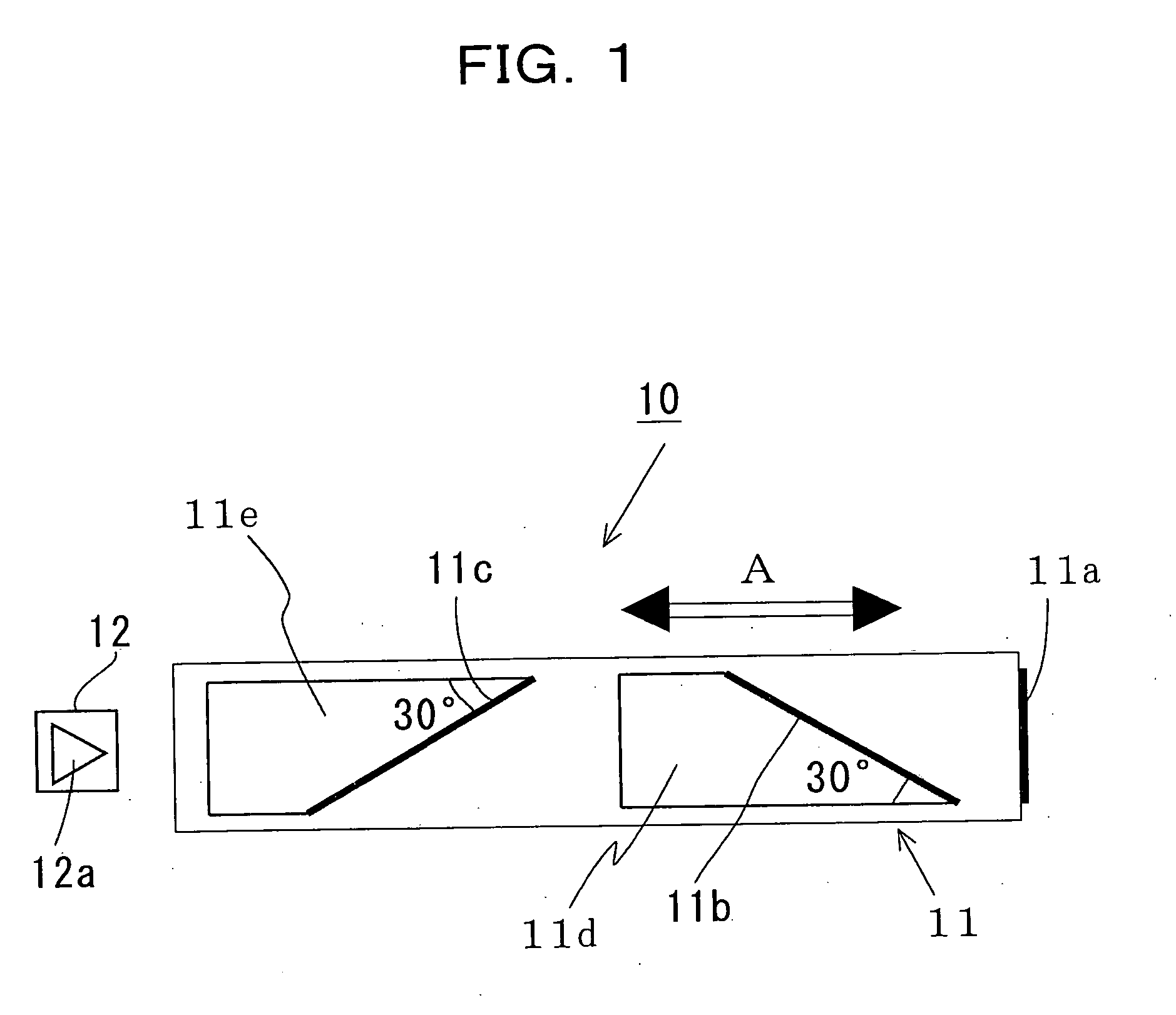

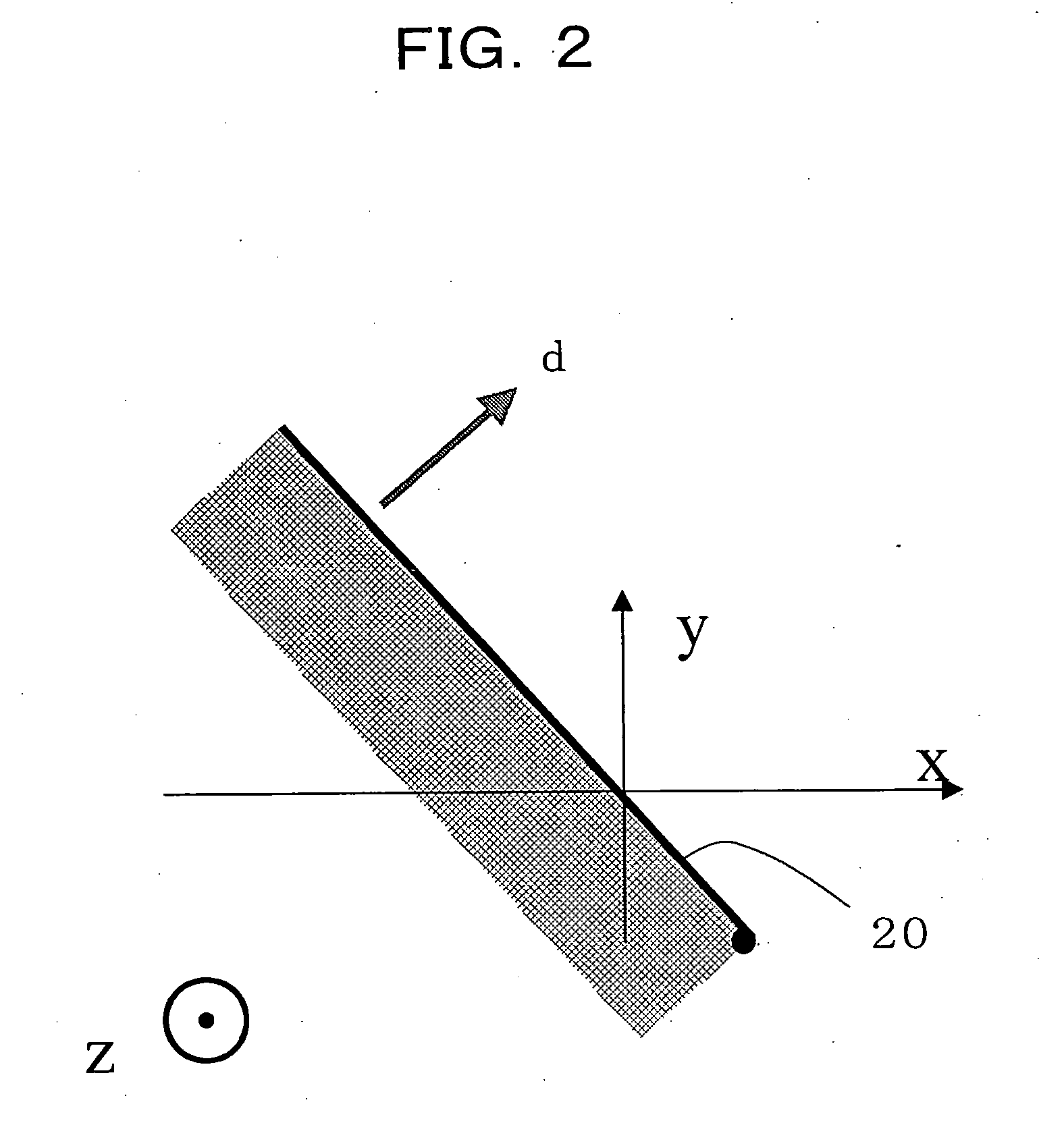

[0052] At the outset, it should be noted that in making a thin film of a ternary phase diagrammatic system by means of a masking mechanism or device for a film forming apparatus according to the present invention, the components that make up the ternary system, as in a manner as described above in connection with the prior art for a thin film of a binary phase-diagrammatic system, are deposited successively on a common region on a substrate to form their respective thin films successively on this region while controlling the respective directions in which their thickness gradients are to develop and this laminating step is repeated several times until the deposited thin films in combination as a thin film of the ternary phase diagrammatic system have a desired thickness. In forming the composite thin film, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com