Patents

Literature

60 results about "Sodium doping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

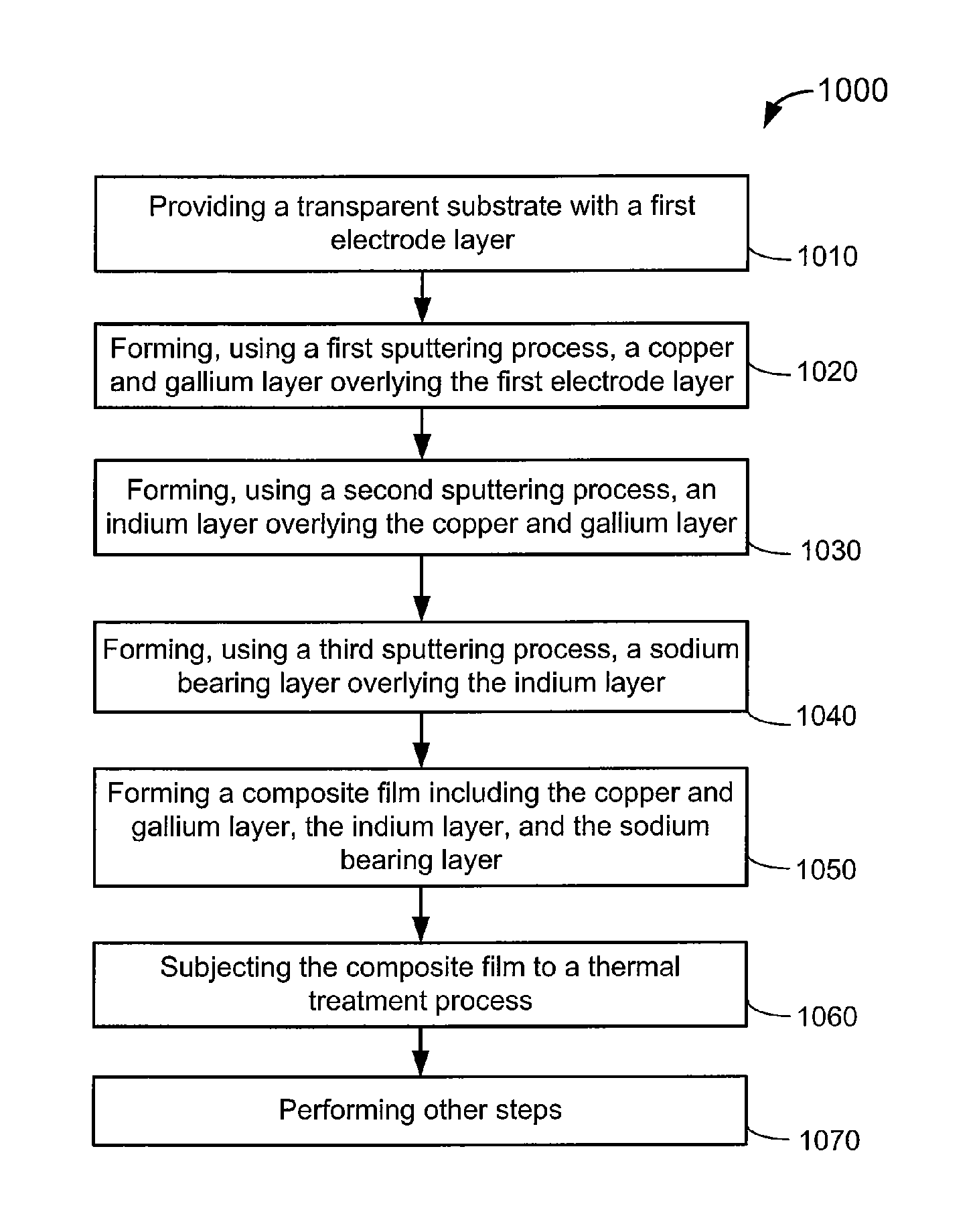

In chamber sodium doping process and system for large scale cigs based thin film photovoltaic materials

A method of processing a photovoltaic materials using a sputtering process including providing at least one transparent substrate having an overlying first electrode layer. The method further including forming an overlying copper and gallium layer using a first sputtering process within a first chamber from a first target including a copper species and a gallium species. Additionally, the method includes forming an indium layer overlying the copper and the gallium layer using a second sputtering process within the first chamber from a second target including an indium species. The method further includes forming a sodium bearing layer overlying the indium layer using a third sputtering process within the first chamber, thereby forming a composite film including the copper and gallium layer, the indium layer, and the sodium bearing layer. Furthermore, the method includes subjecting the composite film to at least a thermal treatment process to form a chalcopyrite absorber layer comprising copper, indium, gallium, and sodium therein.

Owner:CM MFG

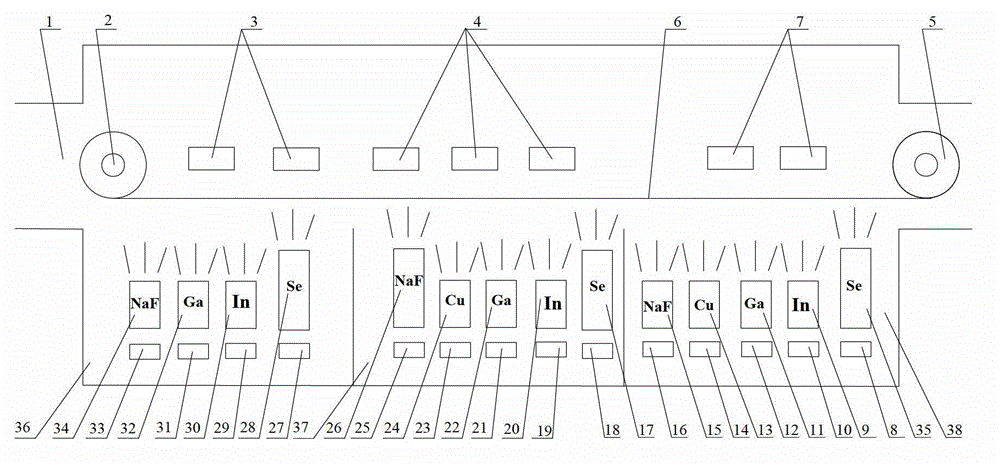

Method for manufacturing sodium-doped absorbing layer on reel-to-reel flexible polyimide (PI) substrate

ActiveCN102943241AGood adhesionIncrease the open circuit voltageFinal product manufactureVacuum evaporation coatingIndiumCopper indium gallium selenide

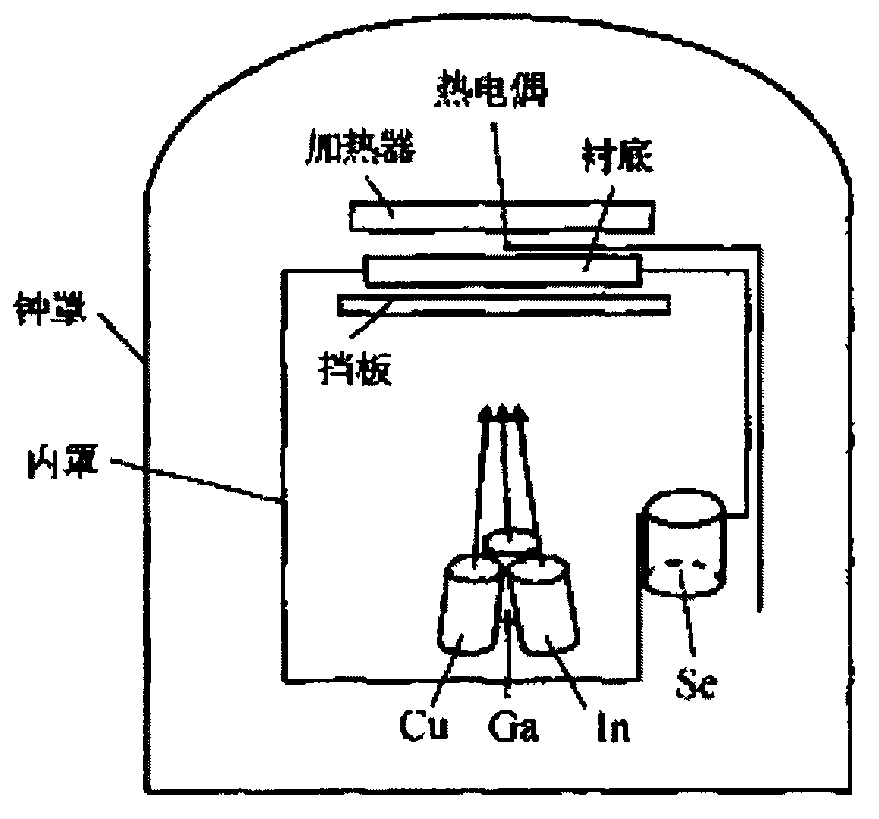

The invention relates to a method for manufacturing a sodium-doped absorbing layer on a reel-to-reel flexible polyimide (PI) substrate. The method is characterized by comprising the steps of 1 performing preparation before work, 2 preparing Na-doped indium gallium selenide (IGS) film, 3 preparing a copper-rich copper indium gallium selenide (CIGS) film; and 4 preparing the sodium-doped absorbing layer on the reel-to-reel flexible PI substrate. The method adopts a vacuum evaporation technology, keeps a distance between evaporation sources and the PI substrate to be 300-400mm and adjusts tape transporting speed of the PI substrate to enable the PI substrate to be lower than 450 DEG C, elements evaporated by the evaporation sources can be compounded on a back electrode Mo of the PI substrate well, and the Na-doped IGS film with even thickness is formed on the back electrode Mo. Due to the fact that Na atoms diffuse and enter the crystal boundary position of the IGS film to form a deep energy level defect, a foundation is laid for fully even Na doping into a large-area absorbing layer and strengthening of adhesion of the absorbing layer, and the effects of improving open-circuit voltage and electrical property of batteries are played.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

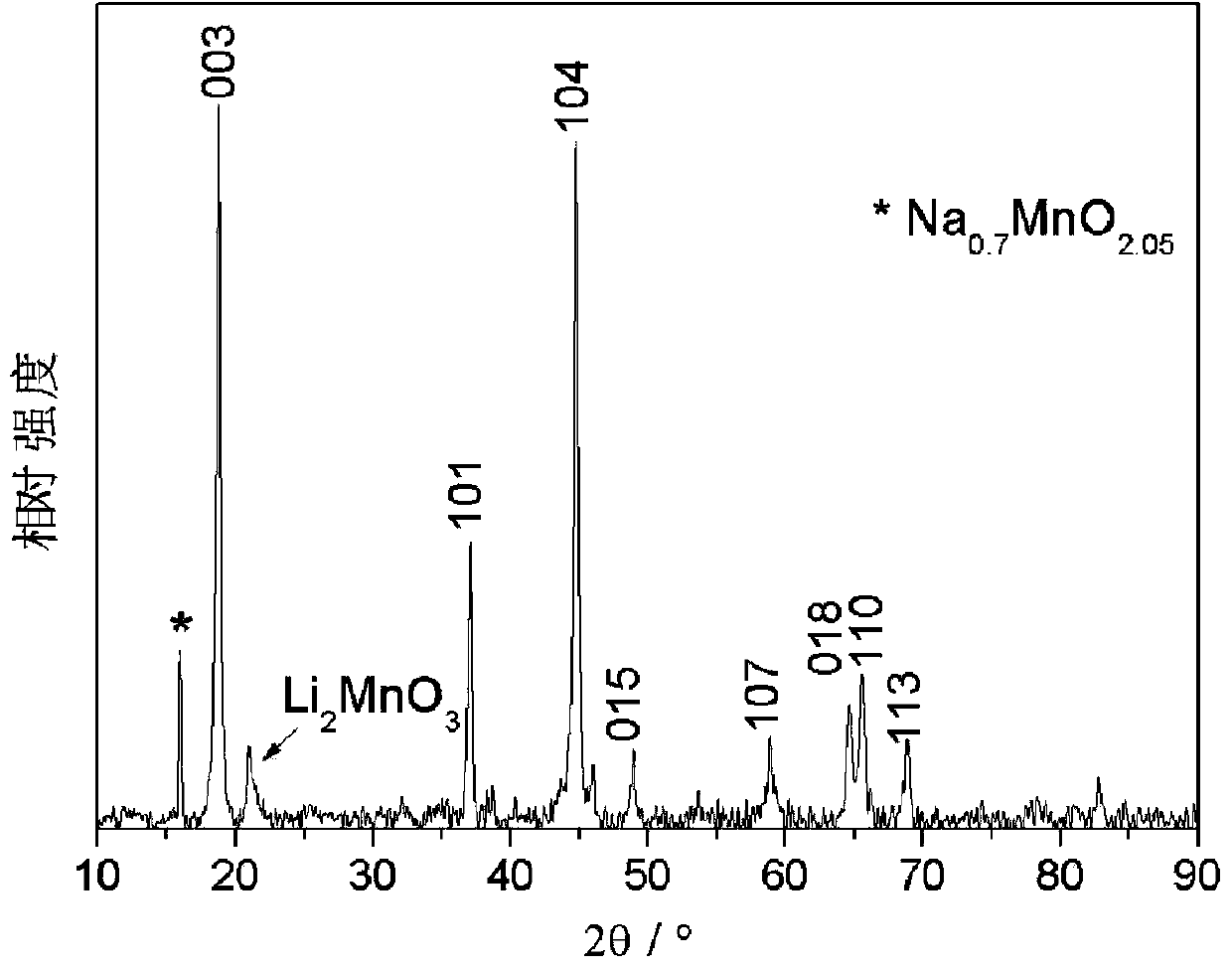

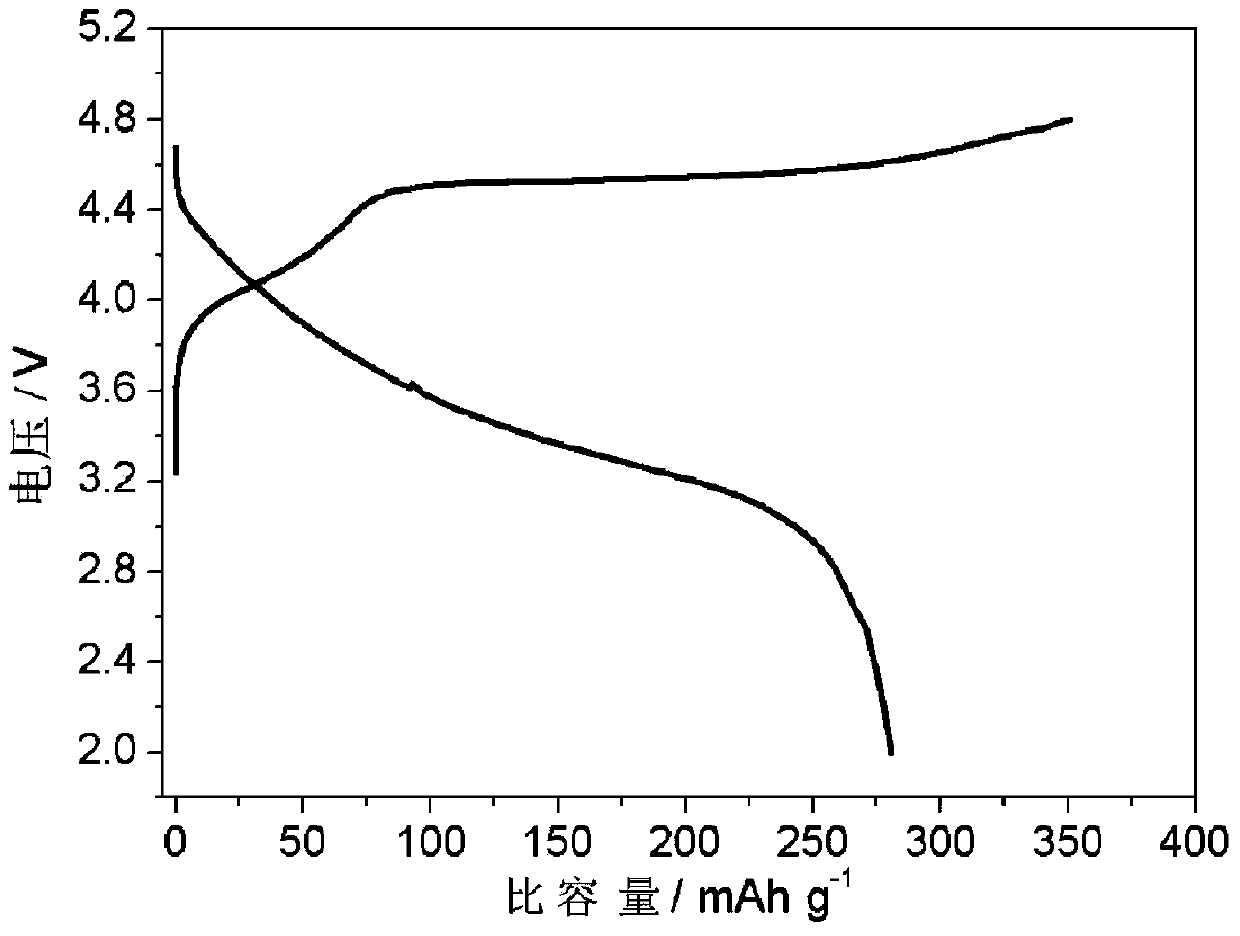

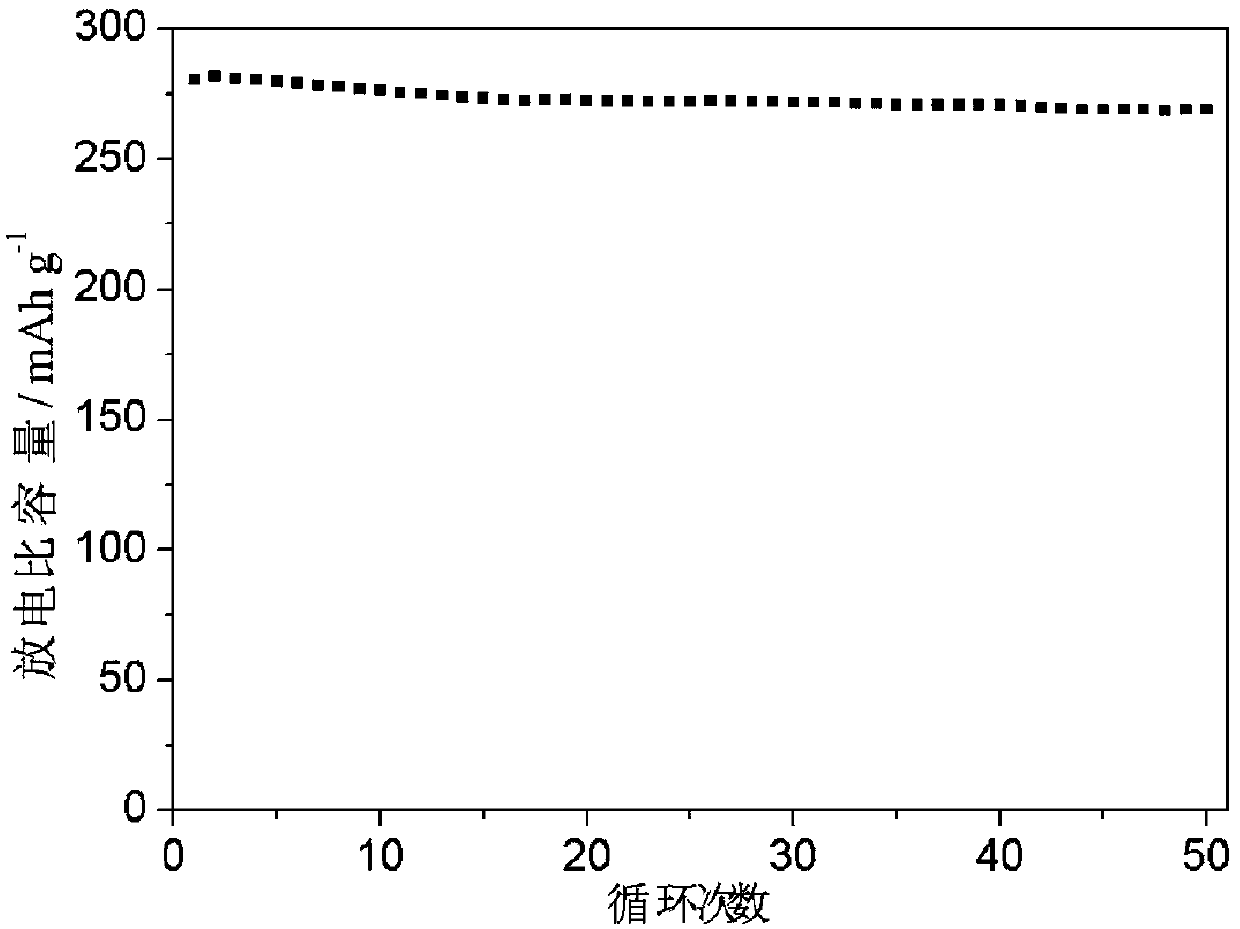

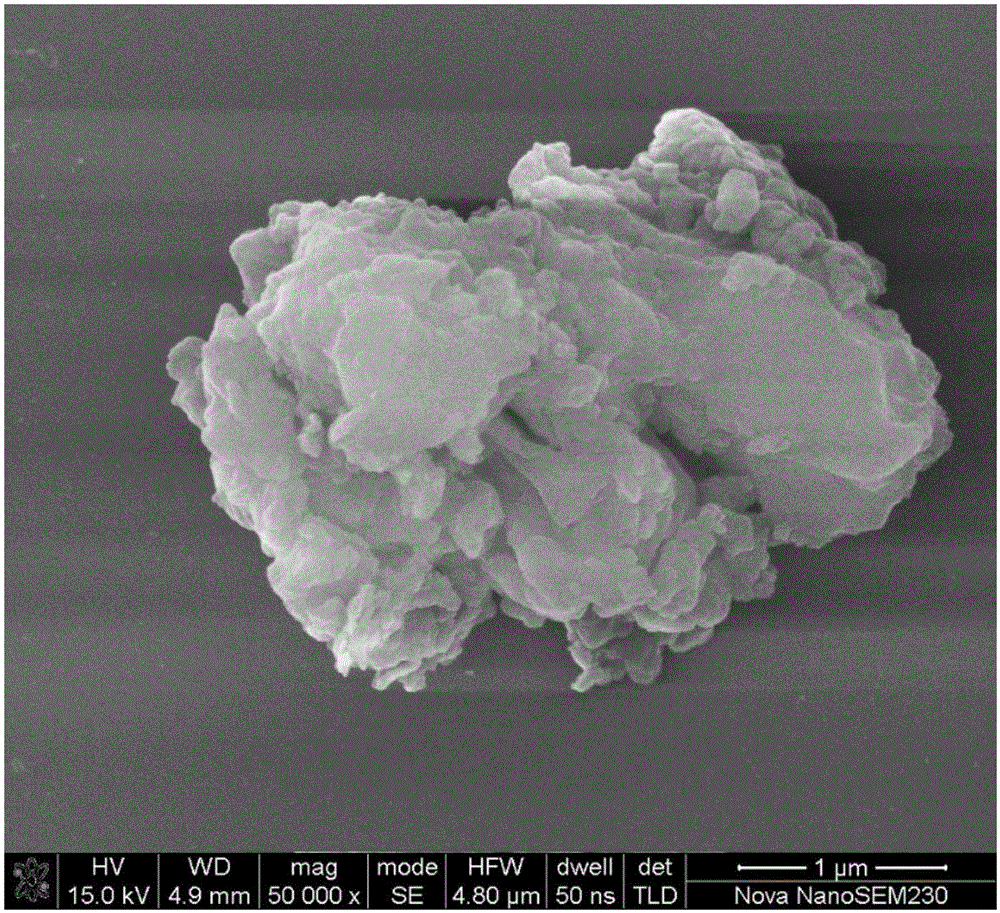

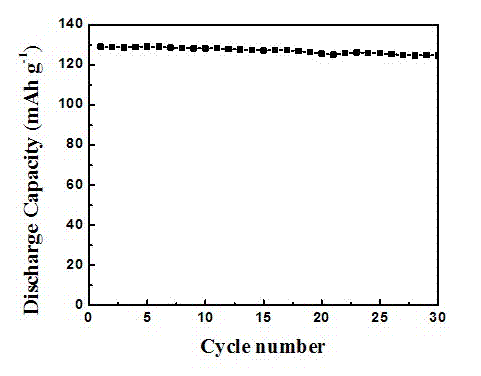

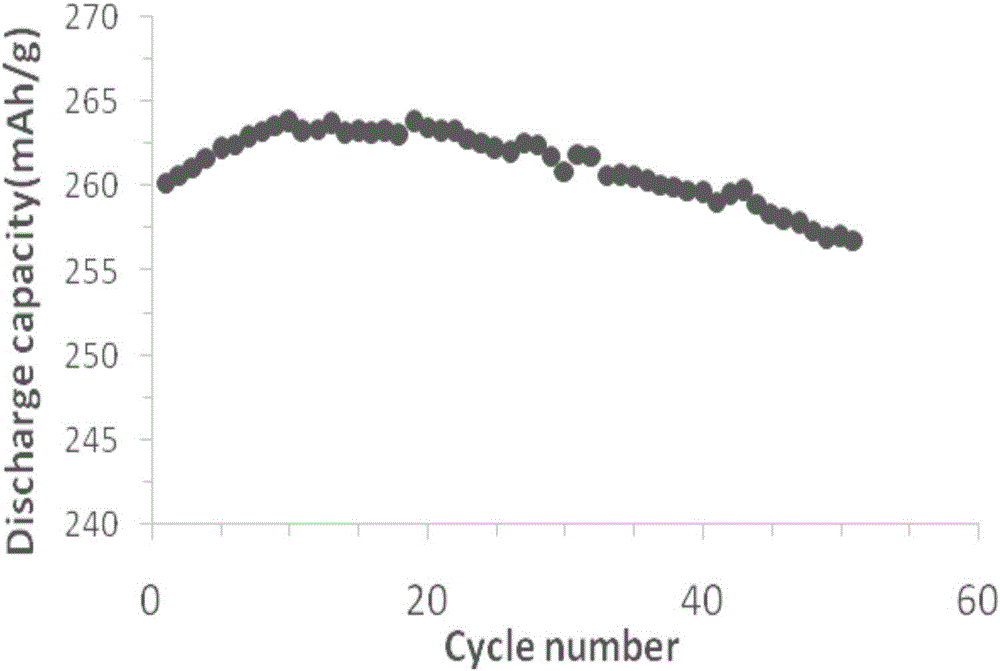

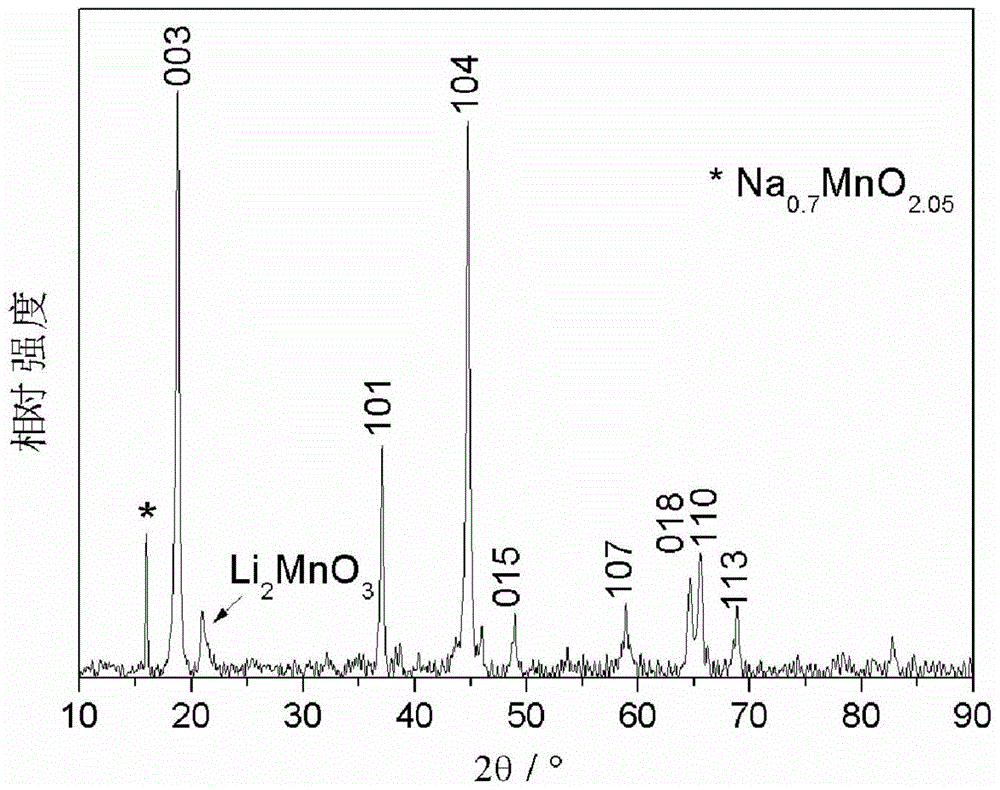

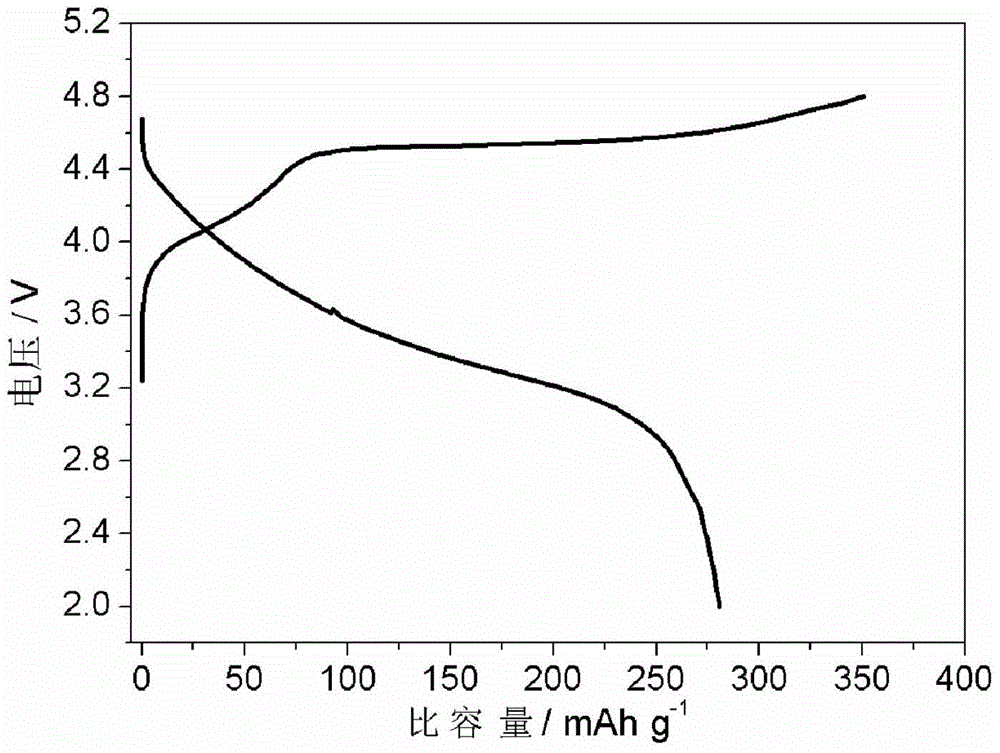

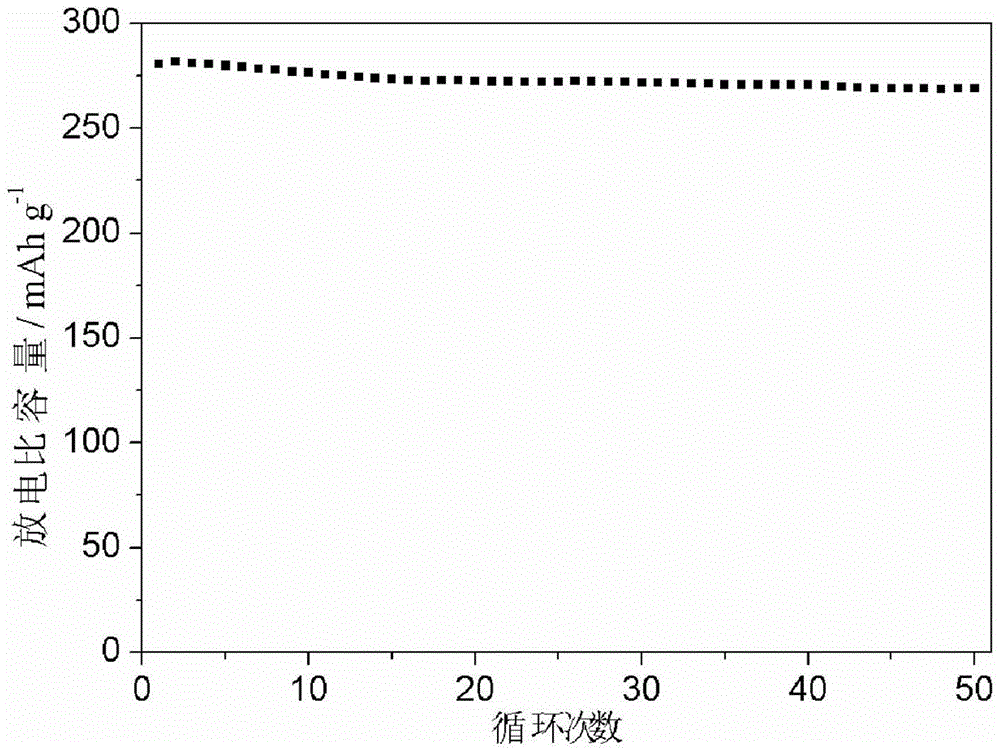

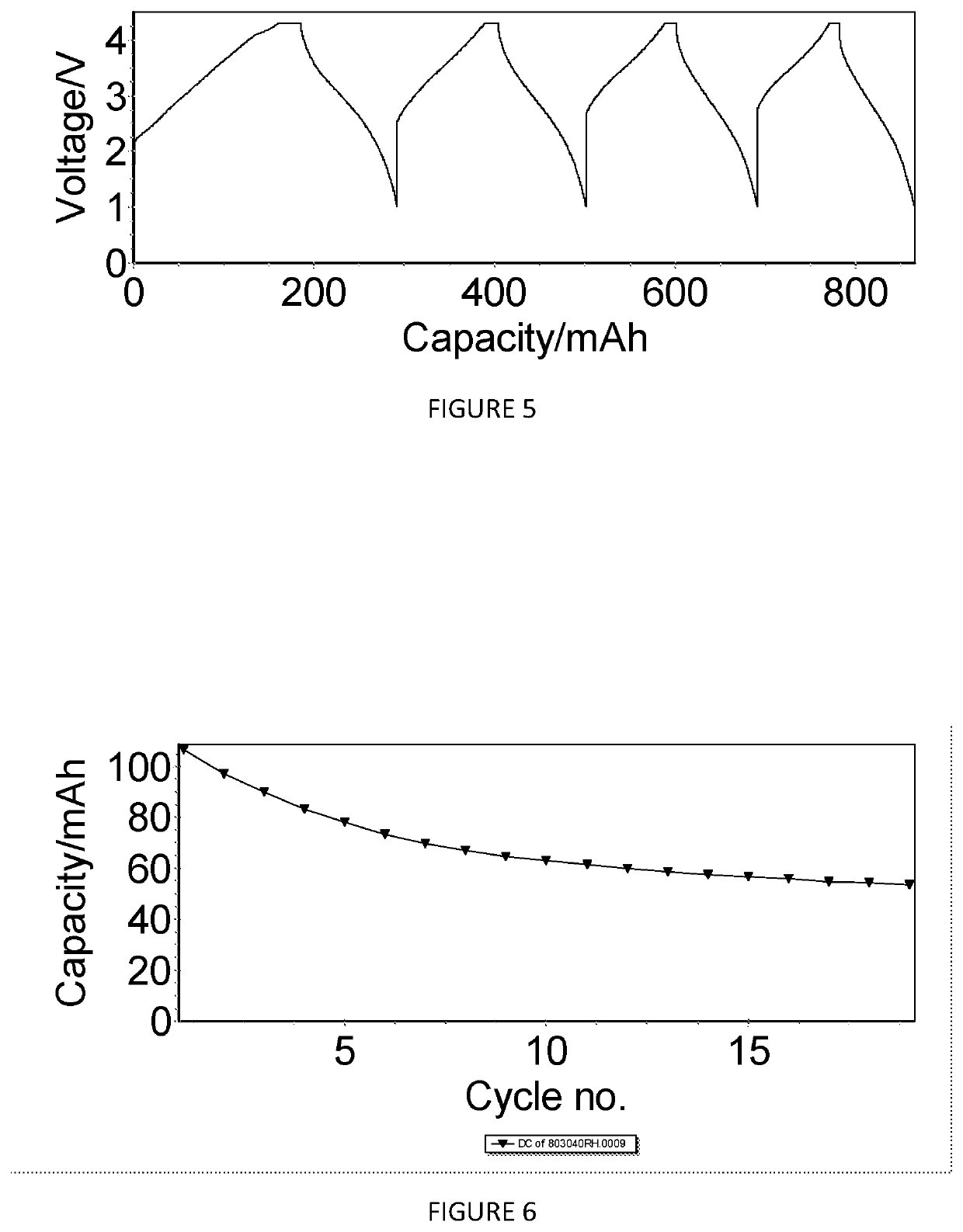

Sodium doped lithium-rich manganese based cathode material for lithium ion battery and preparation method thereof

ActiveCN104201337AImprove discharge specific capacityImprove cycle stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a sodium doped lithium-rich manganese based cathode material for a lithium ion battery. The material is a sodium salt doped lithium-rich manganese based solid solution cathode material of which the general formula is xLi[Li1 / 3Mn2 / 3]O2.(1-x)LiNi0.2Co0.2Mn0.6O2, wherein x is equal to or greater than 0.4 and is equal to or less than 0.7, the doped quantity of sodium elements is 1-10% of the mol content of lithium elements, and the sodium salt is one selected from Na2CO3, Na2C2O4 and NaNO3. The mol content of ternary phase manganese of the sodium doped lithium-rich manganese based cathode material for the lithium ion battery is greater than 50%, and the manganese with high reserves and low price is used for replacing cobalt and nickel, so that the application cost can be reduced. Compared with the prior art, the sodium doping provided by the invention can improve the discharging specific capacity and the circulating stability of the rich lithium manganese based cathode material.

Owner:HEBEI UNIV OF TECH

Sodium doped graphite phase carbon nitride prepared by one-step synthesis and application thereof

ActiveCN106582765AImprove photocatalytic activityNarrow BandwidthPhysical/chemical process catalystsWater/sewage treatment by irradiationSodium bicarbonateOrganic dye

The invention belongs to the technical field of semiconductor photocatalysis, and particularly relates to a sodium doped graphite phase carbon nitride prepared by one-step synthesis and application thereof. The preparation method comprises the steps of placing melamine and sodium hydrogen carbonate into a ball milling agitator for ball-milling for 8 hours, taking out the mixture, placing the mixture in a alumina crucible with lid for calcination to acquire a solid, washing the solid with 3% salpeter solution, deionized water and ethanol for three times, then drying and grinding to acquire the sodium doped graphite phase carbon nitride. The preparation method has the advantages of being low in material cost, simple in processing process, and high in preparation efficiency. The prepared sodium doped graphite phase carbon nitride has a decreased forbidden band gap. The photocatalytic degradation speed of organic dye RhB is increased by leaps and bounds.

Owner:CENT SOUTH UNIV

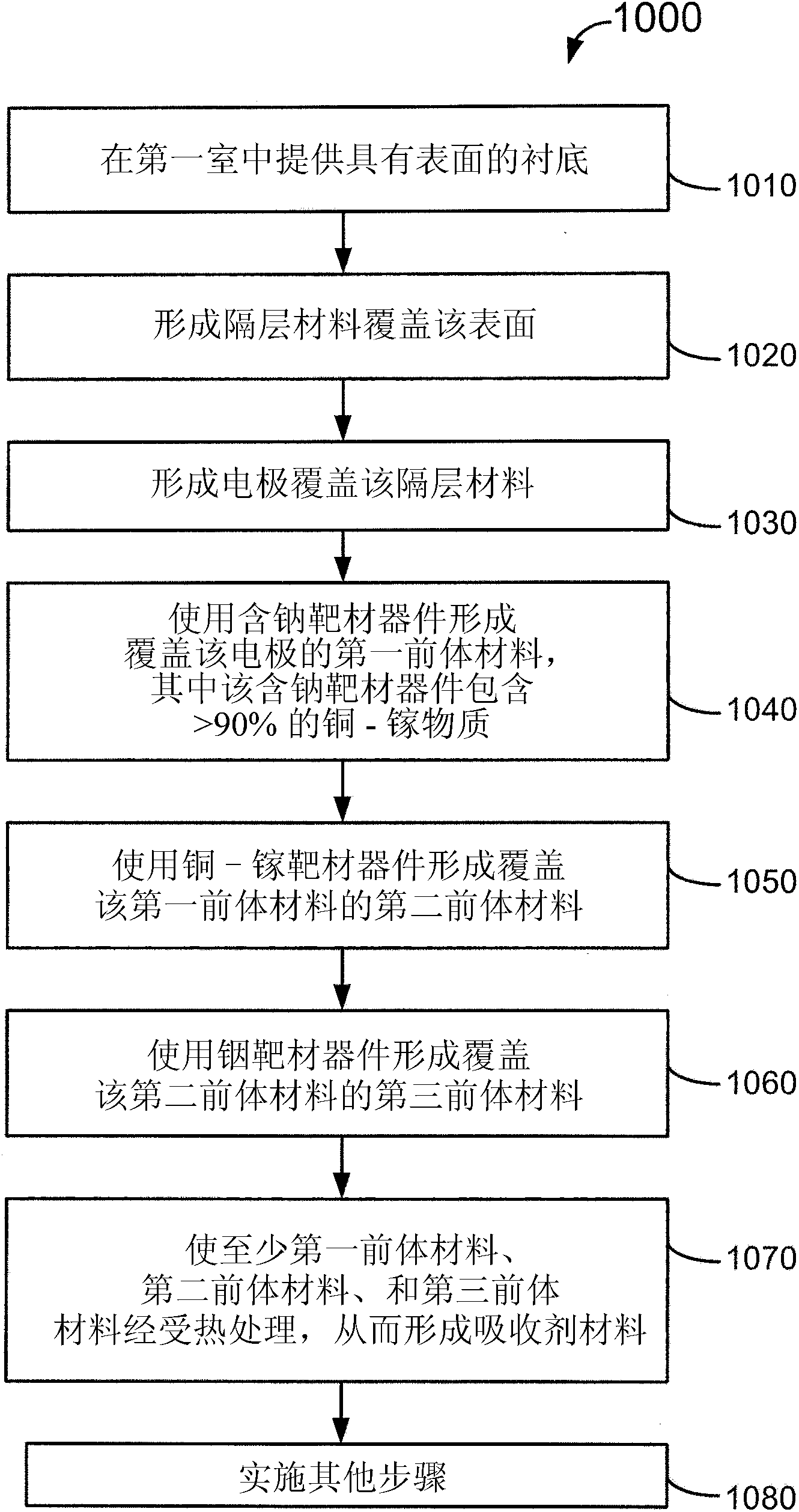

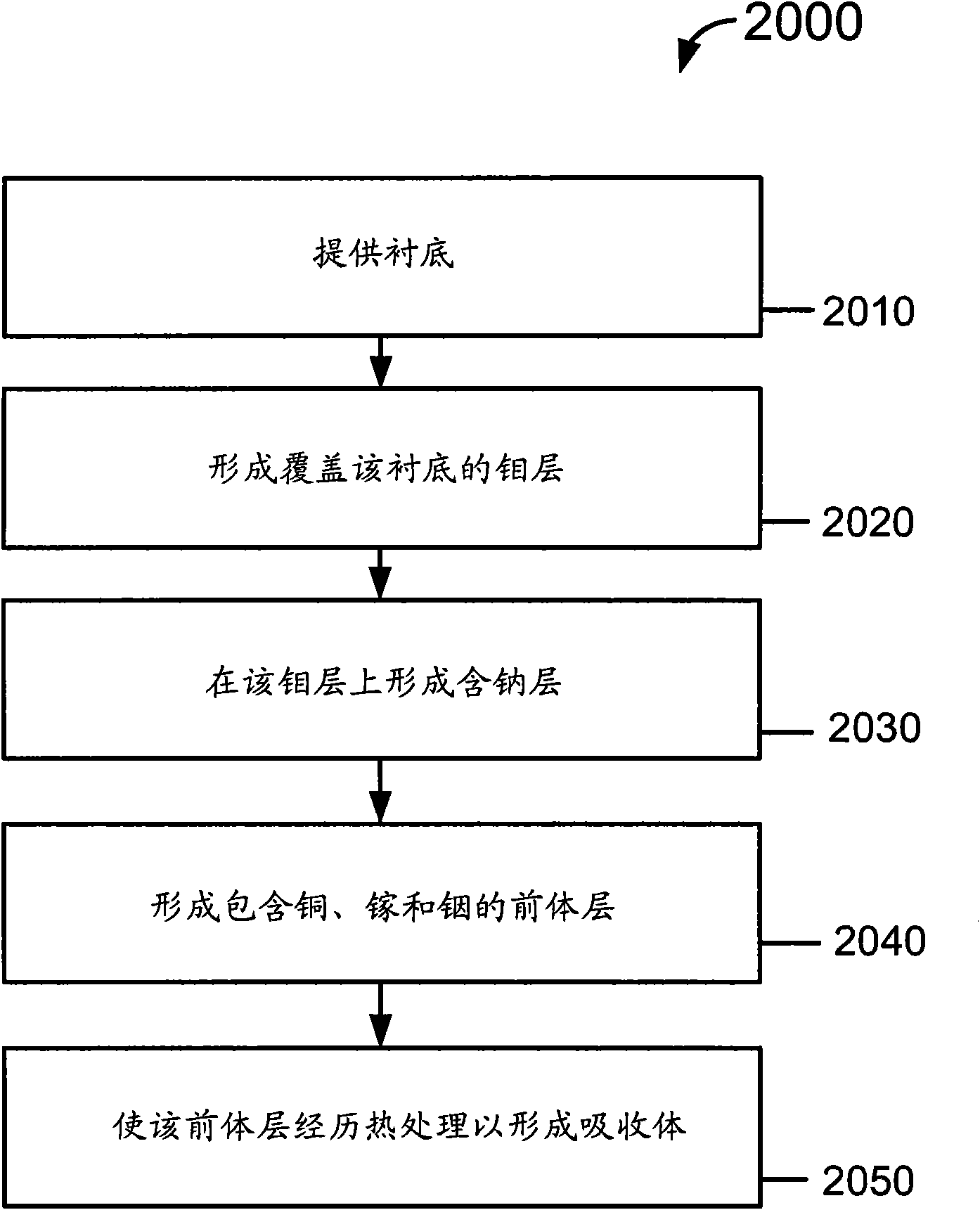

Sodium sputtering doping method for large scale cigs based thin film photovoltaic material

InactiveCN102347398AVacuum evaporation coatingSemiconductor/solid-state device manufacturingIndiumMetallic electrode

A method of processing sodium doping for thin-film photovoltaic material includes forming a metallic electrode on a substrate. The invention also discloses a structure used for forming the photovoltaic material. A sputter deposition using a first target device comprising 4-12 wt% of Na 2 SeO 3 and 88-96 wt% of copper-gallium species is used to form a first precursor with a first Cu / Ga composition ratio. A second precursor over the first precursor has copper species and gallium species deposited using a second target device with a second Cu / Ga composition ratio substantially equal to the first Cu / Ga composition ratio. A third precursor comprising indium material overlies the second precursor. The precursor layers are subjected to a thermal reaction with at least selenium species to cause formation of an absorber material comprising sodium species and a copper to indium-gallium atomic ratio of about 0.9.

Owner:CM MFG

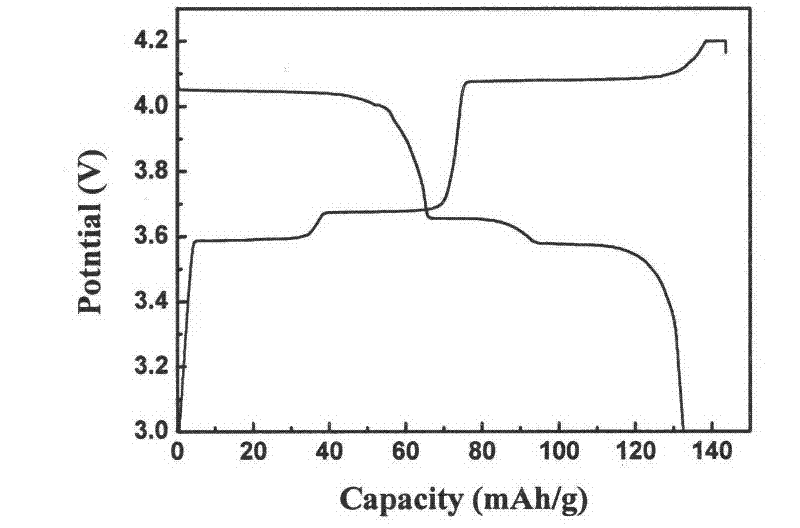

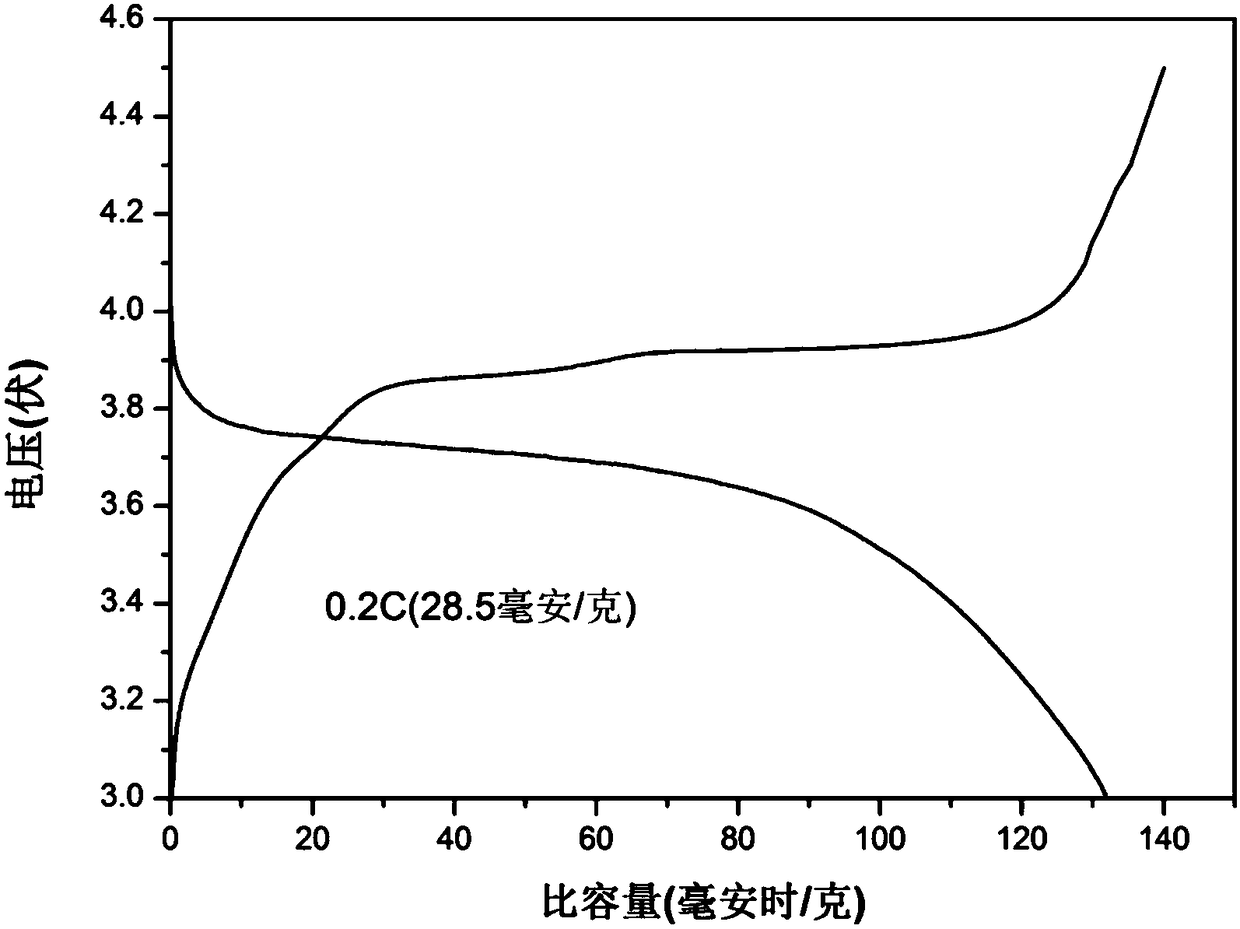

Method for preparing lithium position sodium-doped oxygen lithium vanadium phosphate anode material of lithium ion battery

The invention discloses a method for preparing a lithium position sodium-doped oxygen lithium vanadium phosphate anode material of a lithium ion battery. The nominal constitution formula of the anode material is Li1-xNaxVOPO4 and the doping amount is in a range that x is more than 0 and less than 0.05. The method comprises the following steps of: mixing lithium sources, sodium sources, vanadium sources and phosphorus sources in a certain proportion; adding dispersants into the mixture to perform mixing and ball milling for 4 to 6 hours to obtain rheological jelly; drying the jelly at the temperature of 60 to 80 DEG C for 2 hours and grinding the dried jelly into powder; and sintering the jelly powder in a certain atmosphere at the temperature of 400 to 800 DEG C for 6 to 10 hours to obtain lithium position sodium-doped oxygen lithium vanadium phosphate powder of which the nominal constitution formula is Li1-xNaxVOPO4( x is more than 0 and less than 0.5). In the method, the anode material lithium position sodium-doped oxygen lithium vanadium phosphate powder which is used for secondary Lithium-Ion batteries and doped with the sodium at lithium position and has high crystallinity and uniform content is prepared by simple mixing, ball milling and drying processes, controlling thermal treatment temperature and time, and a rheological phase method suitable for commercial production; and the initial discharge capacity at room temperature is more than 140mAh / g. Compared with pure oxygen lithium vanadium phosphate, the oxygen lithium vanadium phosphate of the invention obviously improves matrix capacities and cycle performance, particularly high-rate cycle performance. The synthesis process of the material is suitable for industrialized production.

Owner:XIANGXI AUTONOMOUS PREFECTURE MINERALS & NEW MATERIAL TECHNOLOGICAL INNOVATION SERVICE CENT +1

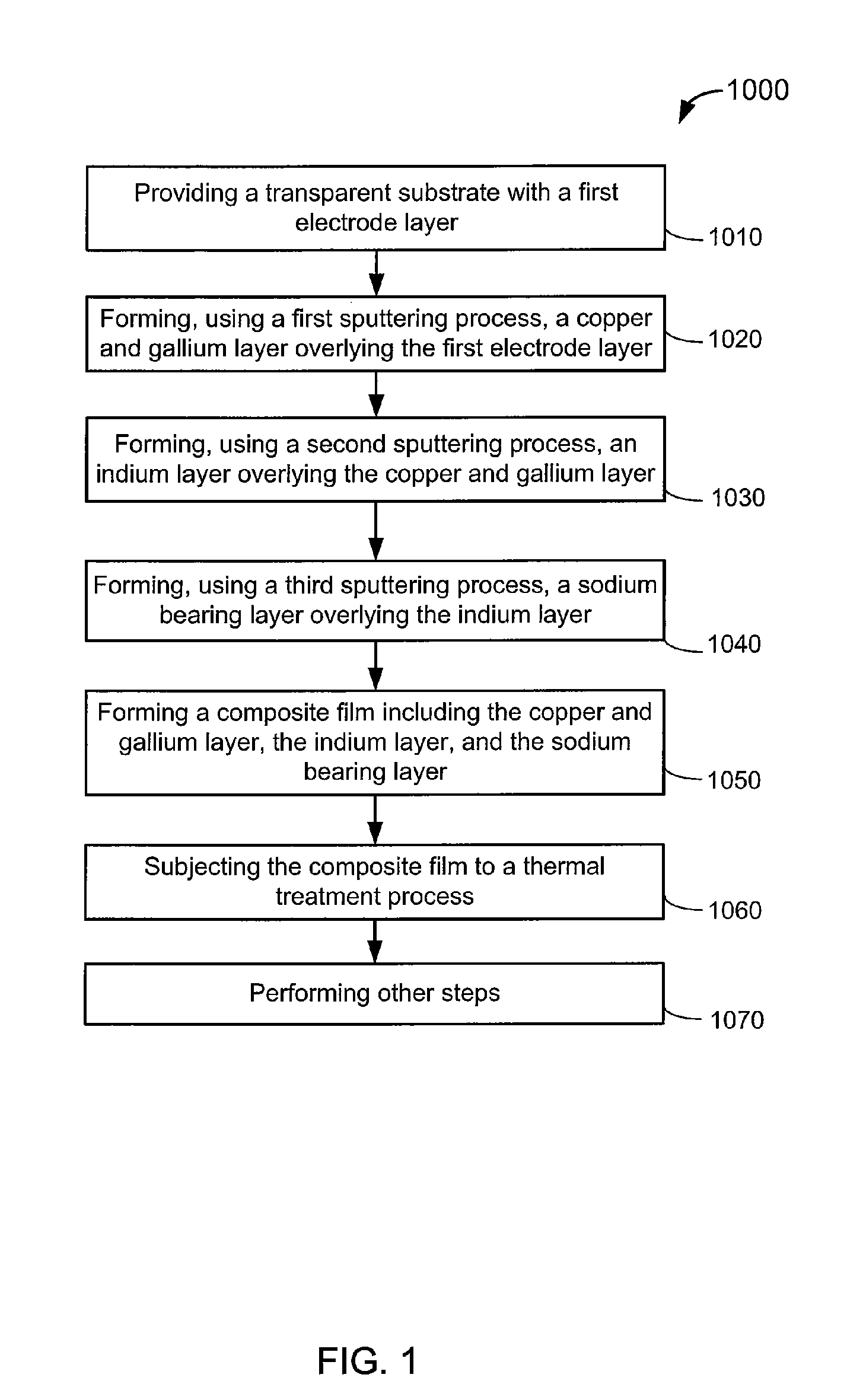

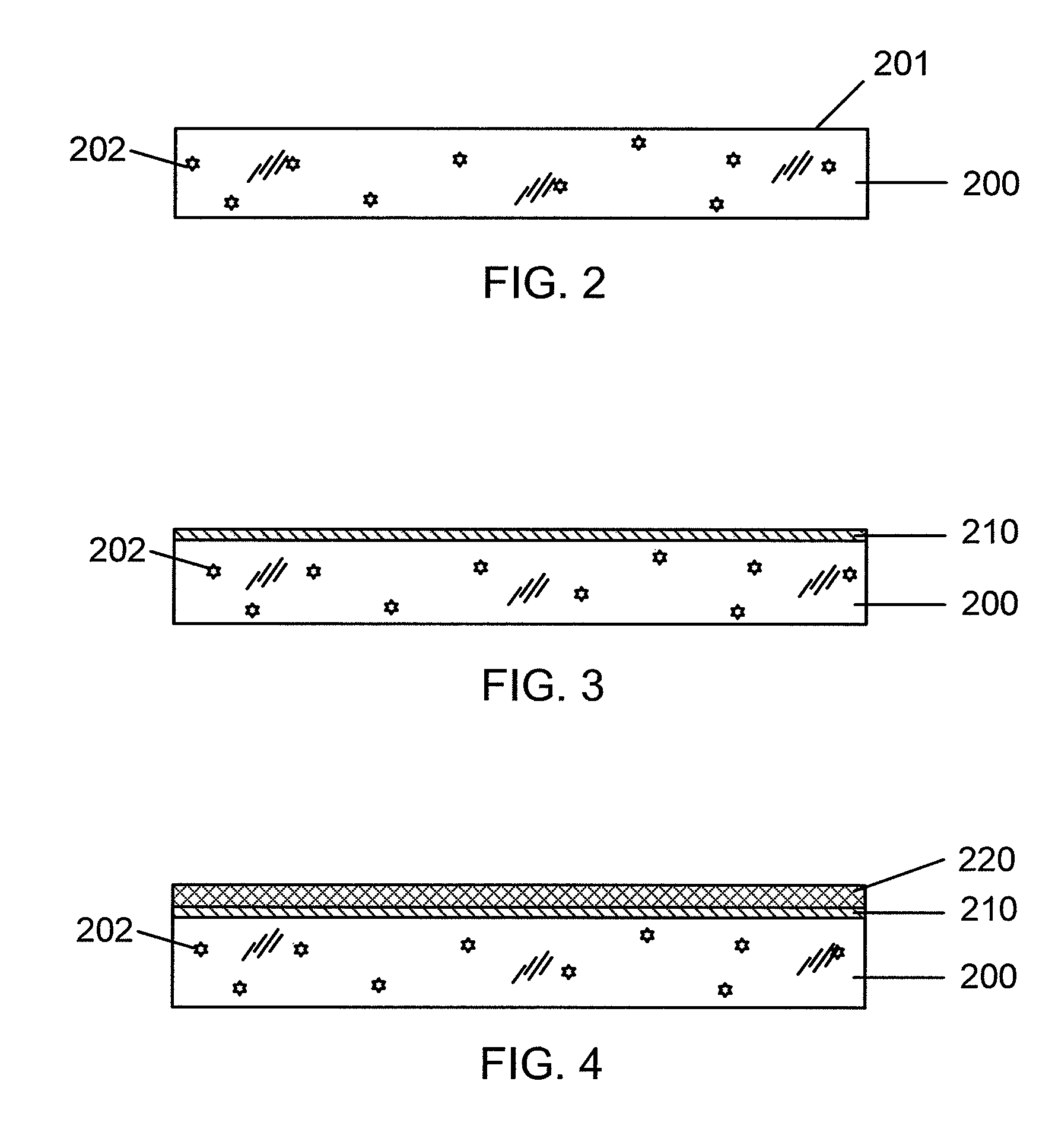

In chamber sodium doping process and system for large scale fabrication of CIGS based thin film photovoltaic materials

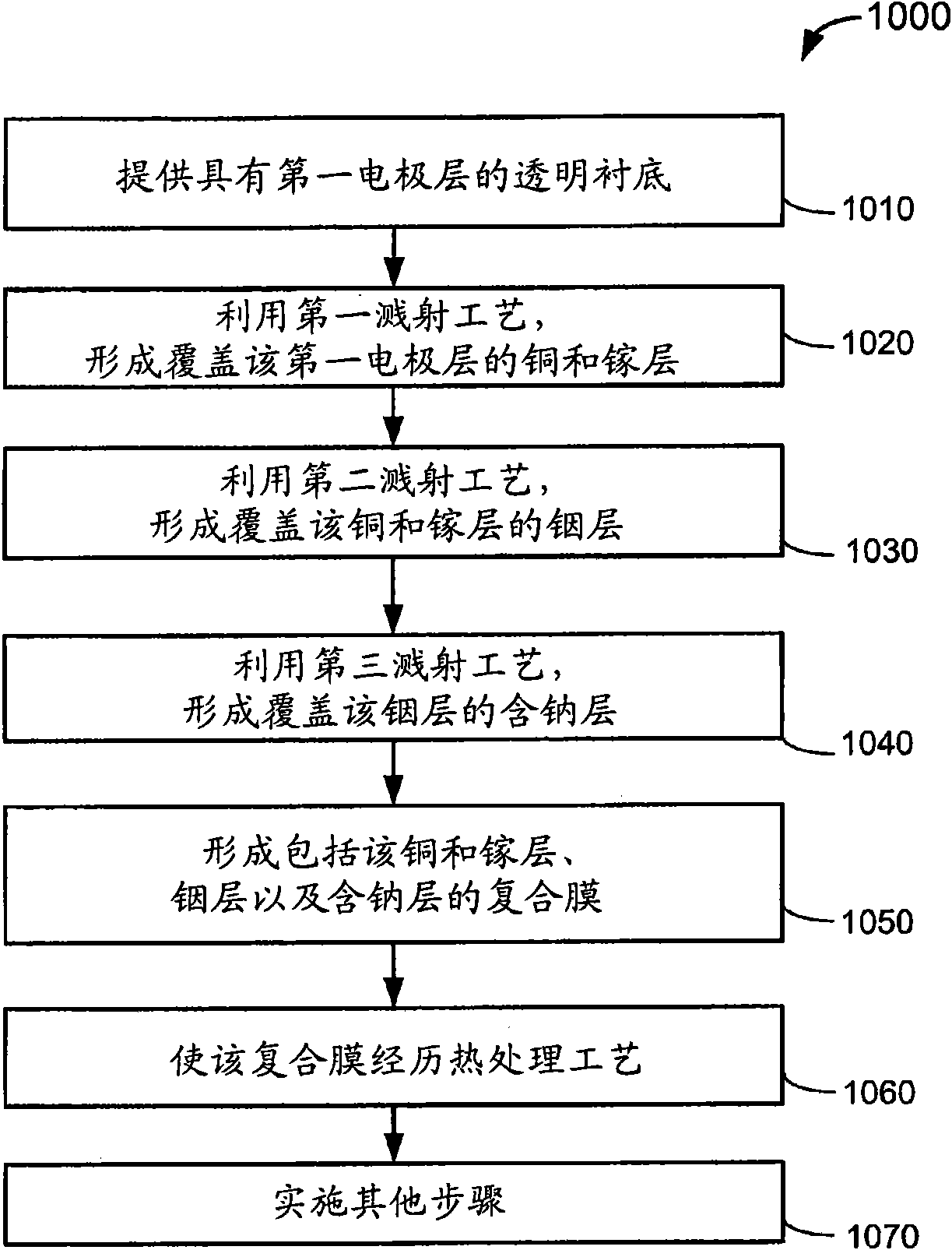

InactiveCN102168252ADoping process is simpleVacuum evaporation coatingSputtering coatingComposite filmIndium

The invention relates to in chamber sodium doping process and system for large scale fabrication of CIGS based thin film photovoltaic materials. A method of processing a photovoltaic materials using a sputtering process including providing at least one transparent substrate having an overlying first electrode layer. The method further including forming an overlying copper and gallium layer using a first sputtering process within a first chamber from a first target including a copper species and a gallium species. Additionally, the method includes forming an indium layer overlying the copper and the gallium layer using a second sputtering process within the first chamber from a second target including an indium species. The method further includes forming a sodium bearing layer overlying the indium layer using a third sputtering process within the first chamber, thereby forming a composite film including the copper and gallium layer, the indium layer, and the sodium bearing layer. Furthermore, the method includes subjecting the composite film to at least a thermal treatment process to form a chalcopyrite absorber layer comprising copper, indium, gallium, and sodium therein.

Owner:CM MFG

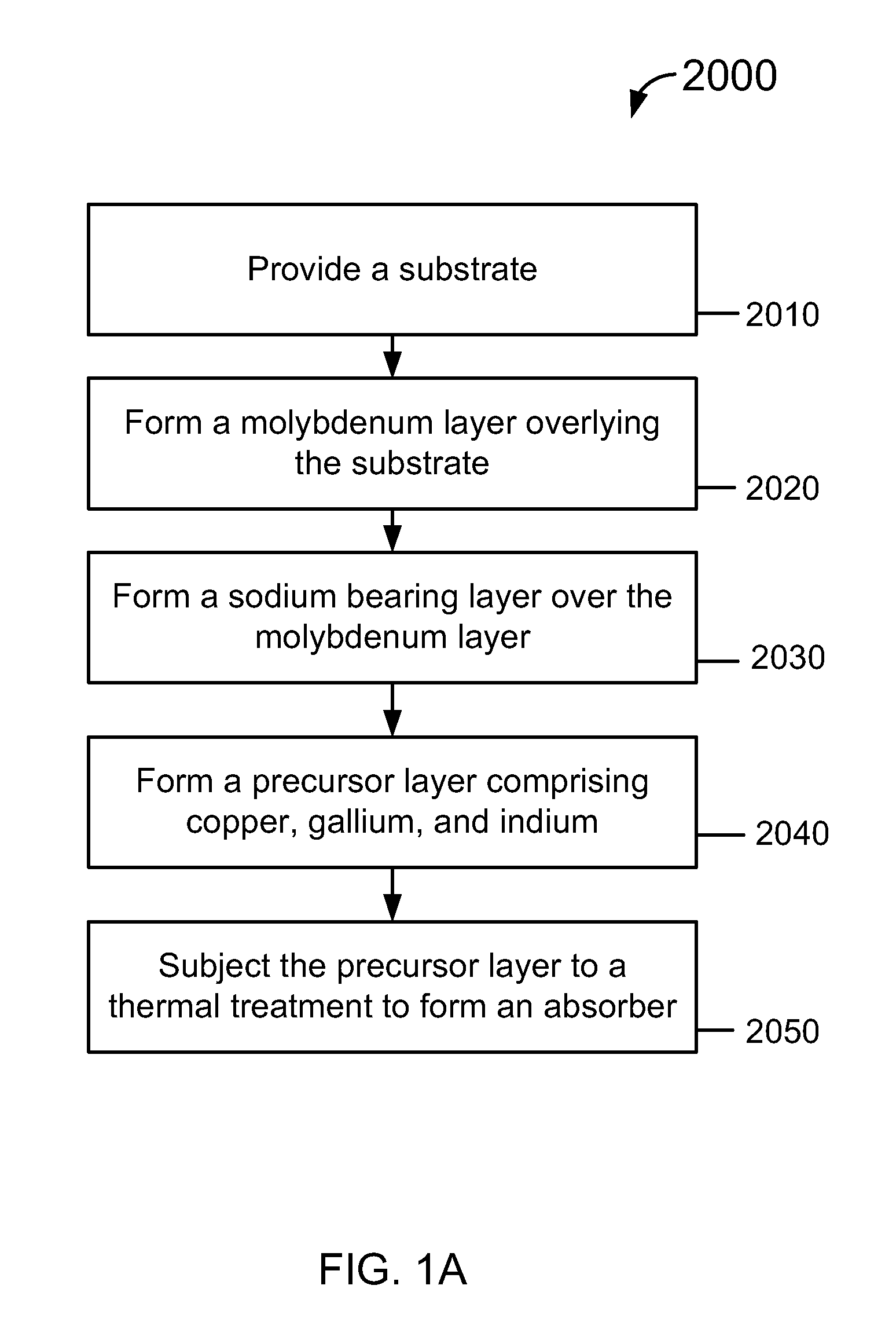

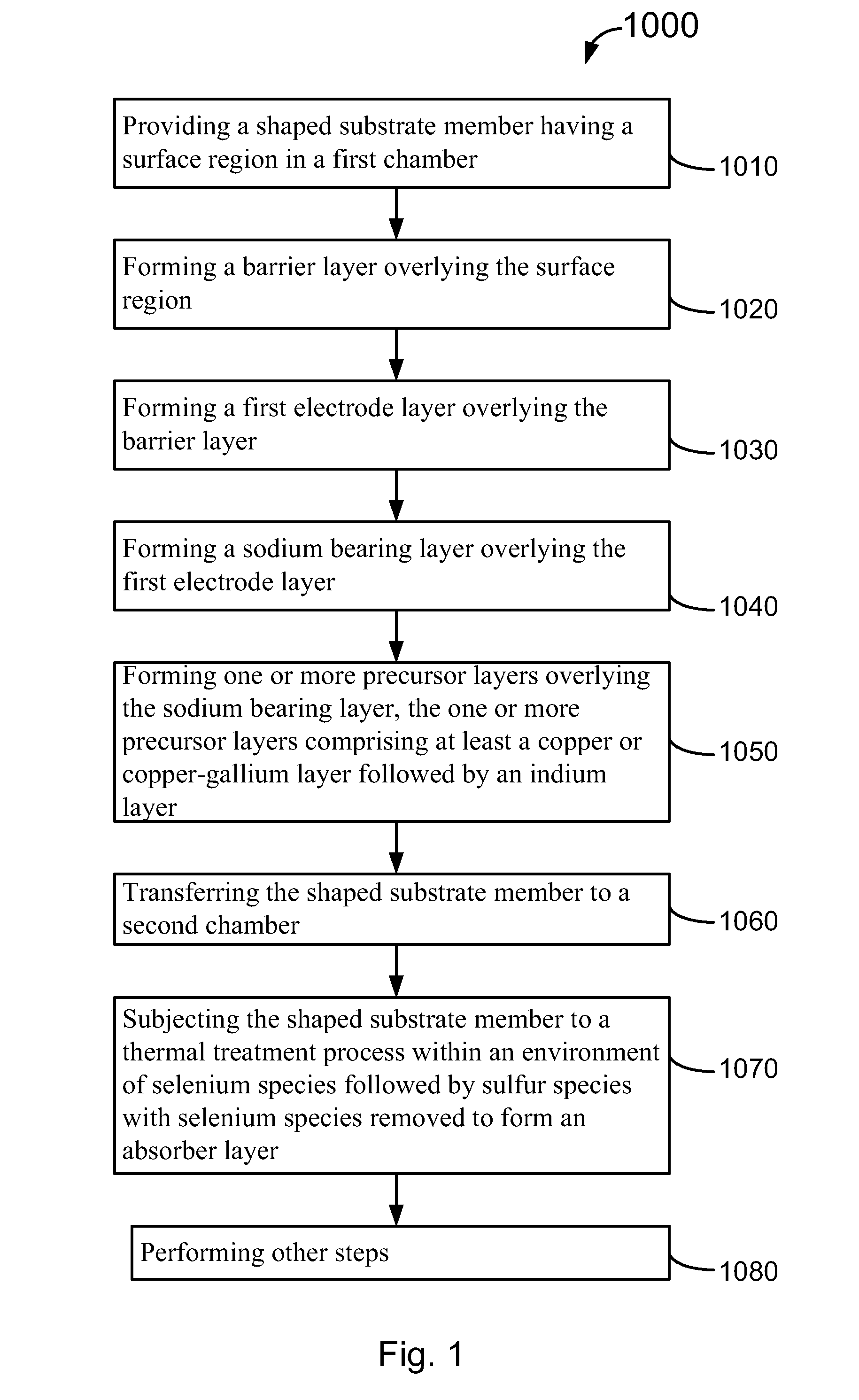

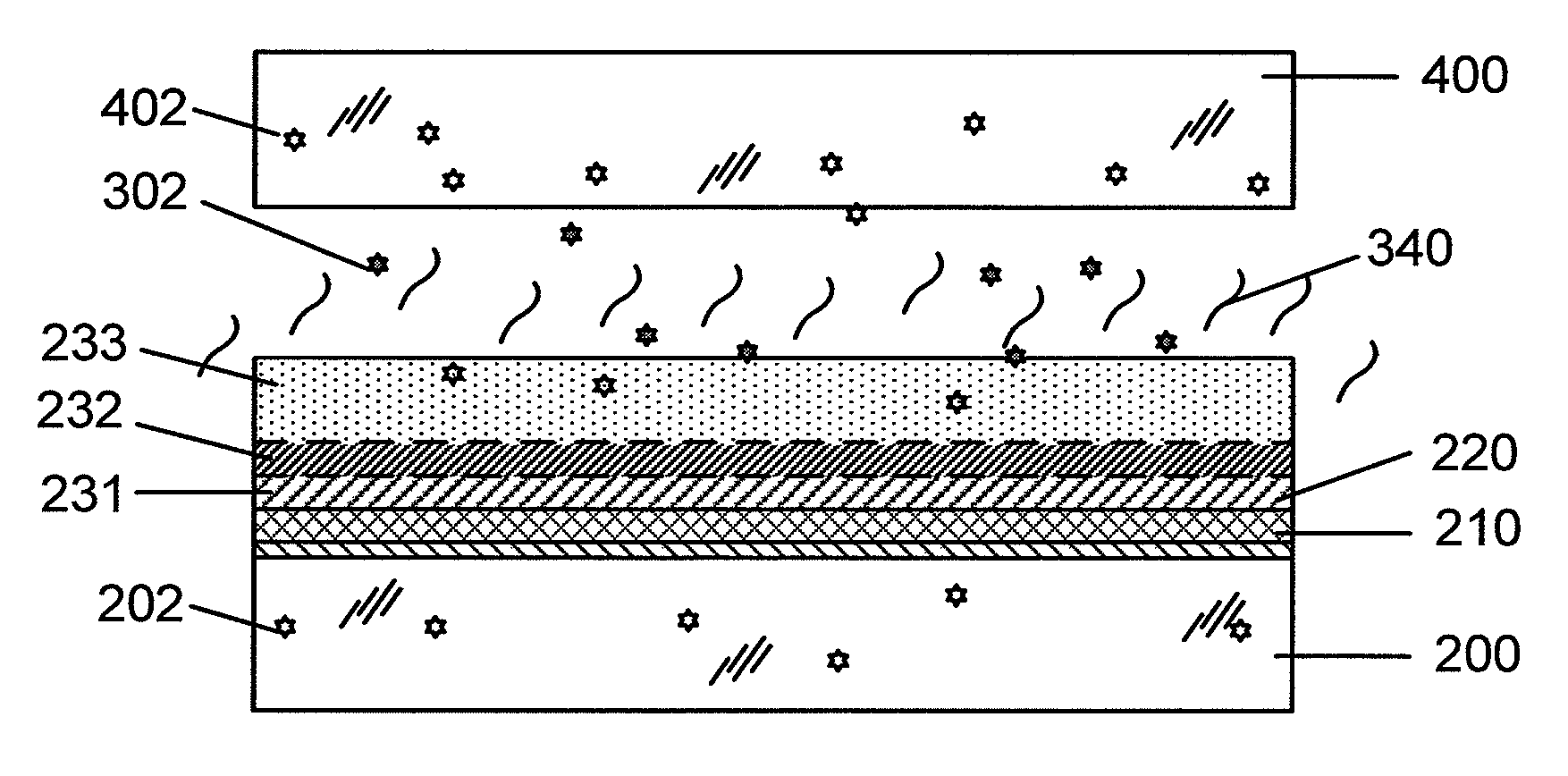

Sodium doping method and system for shaped CIGS/CIS based thin film solar cells

InactiveUS8241943B1OptimizationAvoid undesired absorptionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumGas phase

A method of sodium doping in fabricating CIGS / CIS based thin film solar cells includes providing a shaped substrate member. The method includes forming a barrier layer over the surface region followed by a first electrode layer, and then a sodium bearing layer. A precursor layer of copper, indium, and / or gallium materials having an atomic ratio of copper / group III species no greater than 1.0 is deposited over the sodium bearing layer. The method further includes transferring the shaped substrate member to a second chamber and subjecting it to a thermal treatment process within an environment comprising gas-phase selenium species, followed by an environment comprising gas-phase sulfur species with the selenium species being substantially removed to form an absorber layer.

Owner:CM MFG

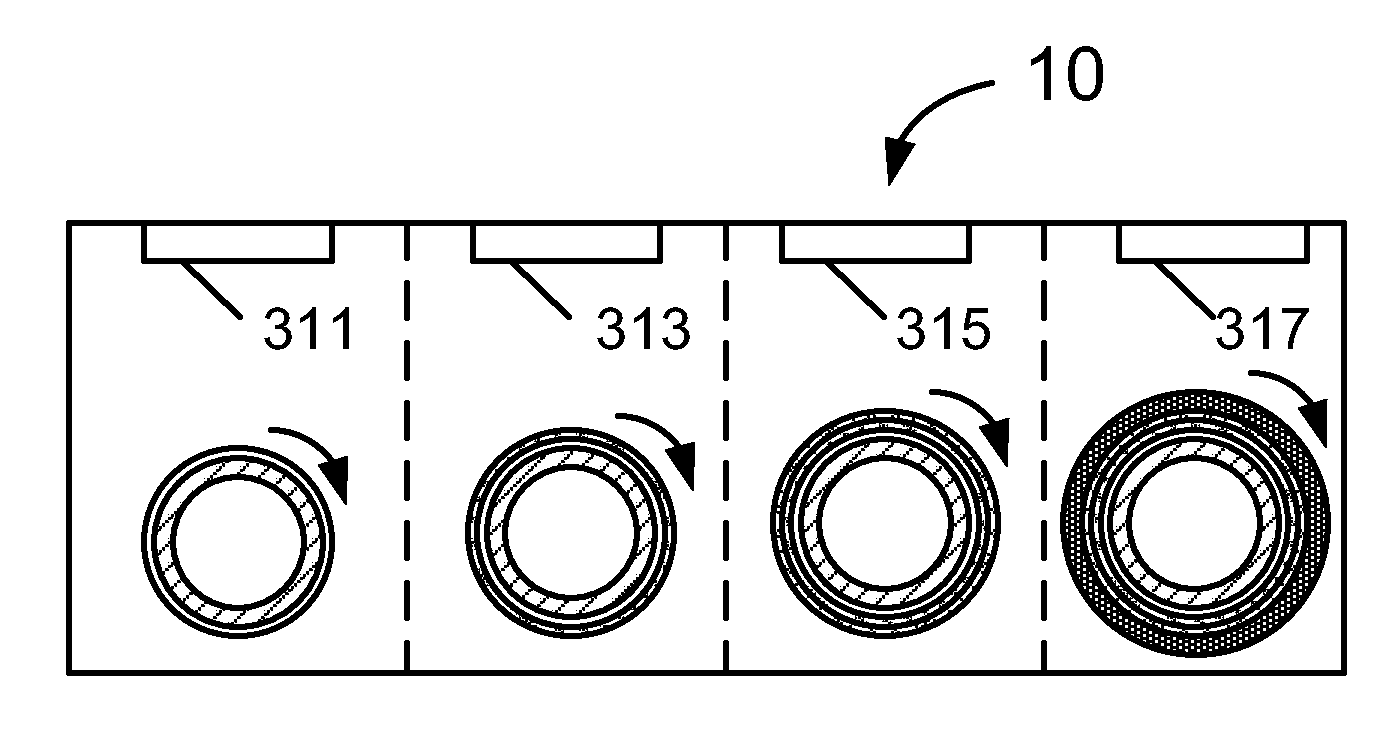

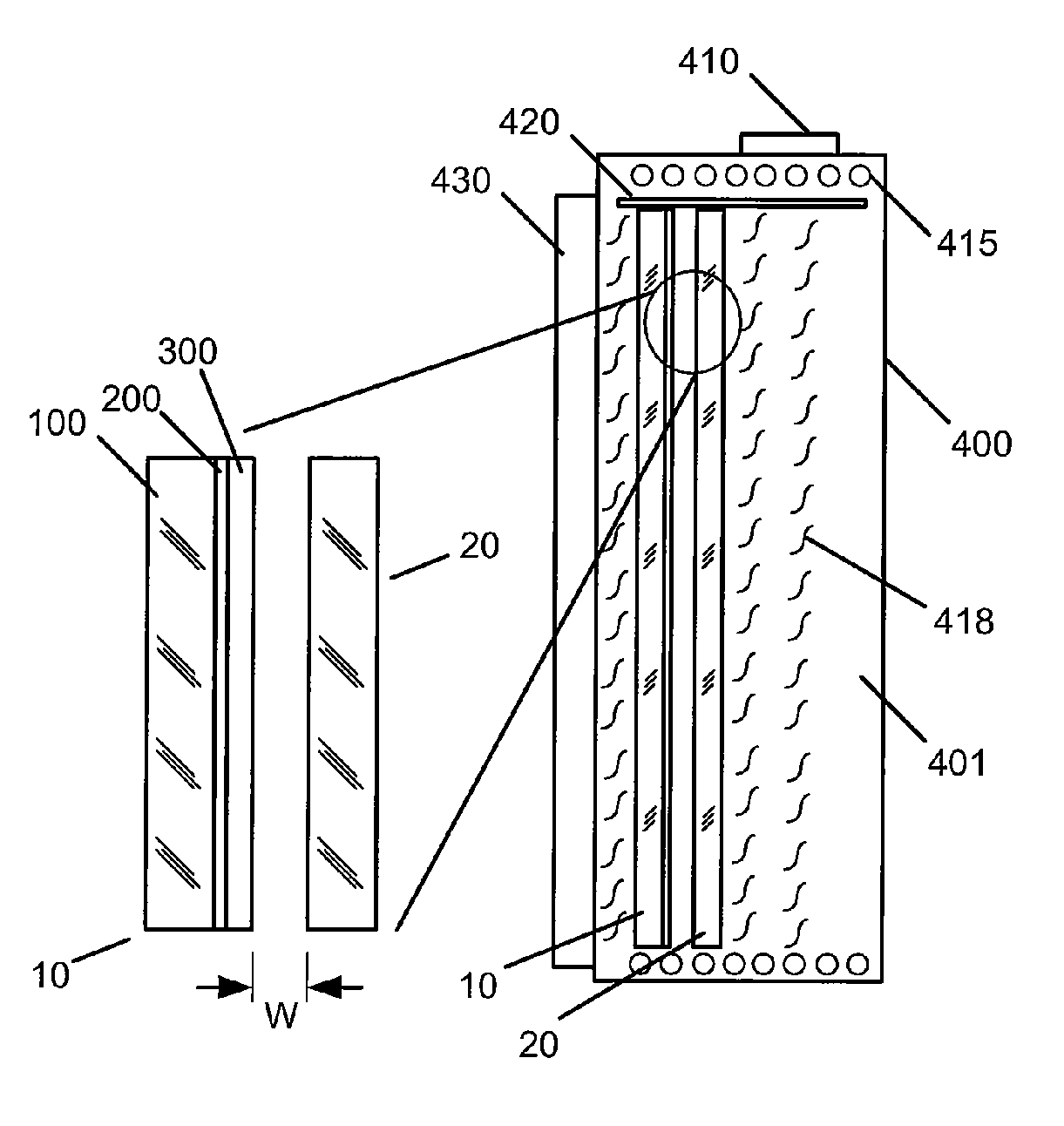

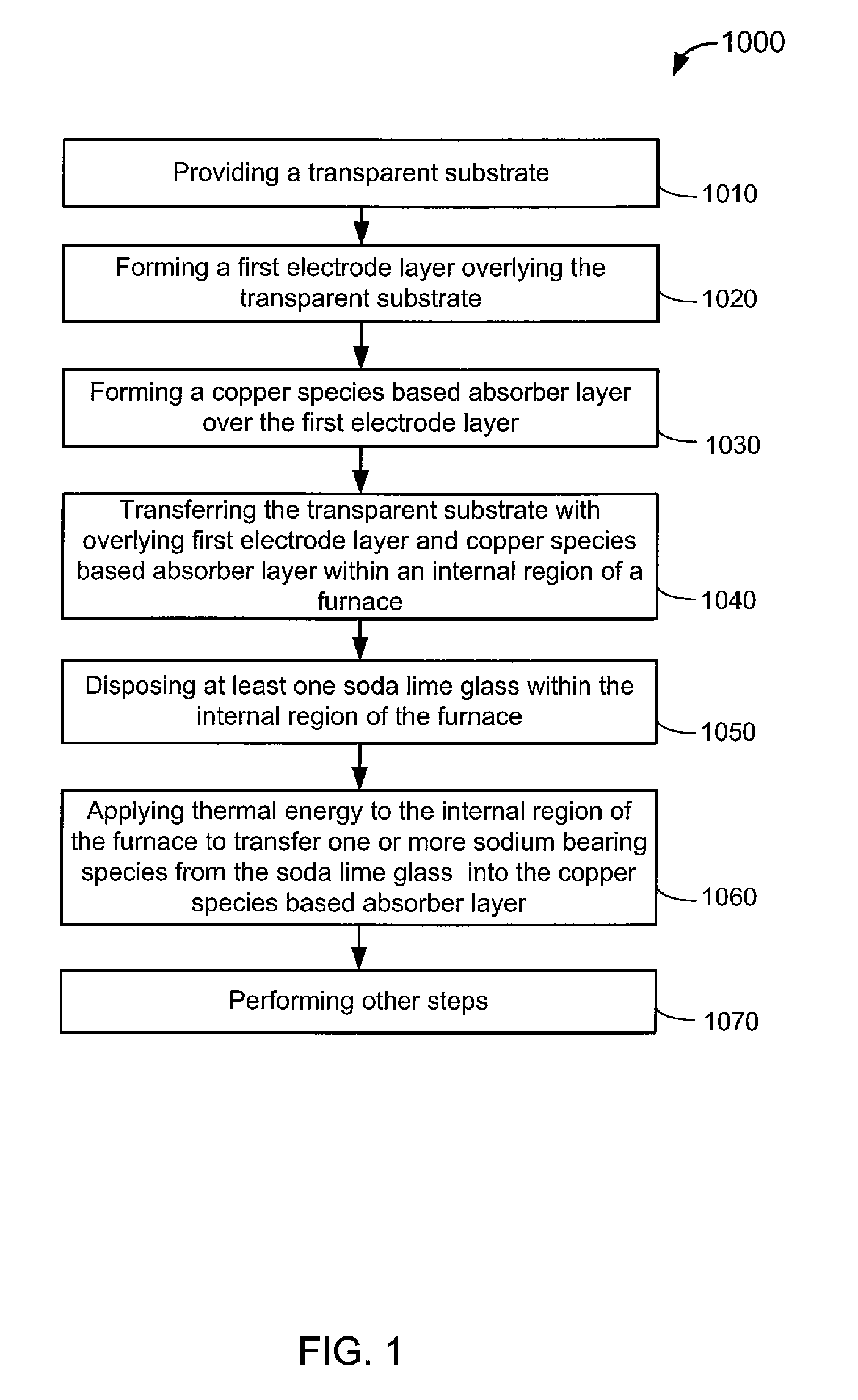

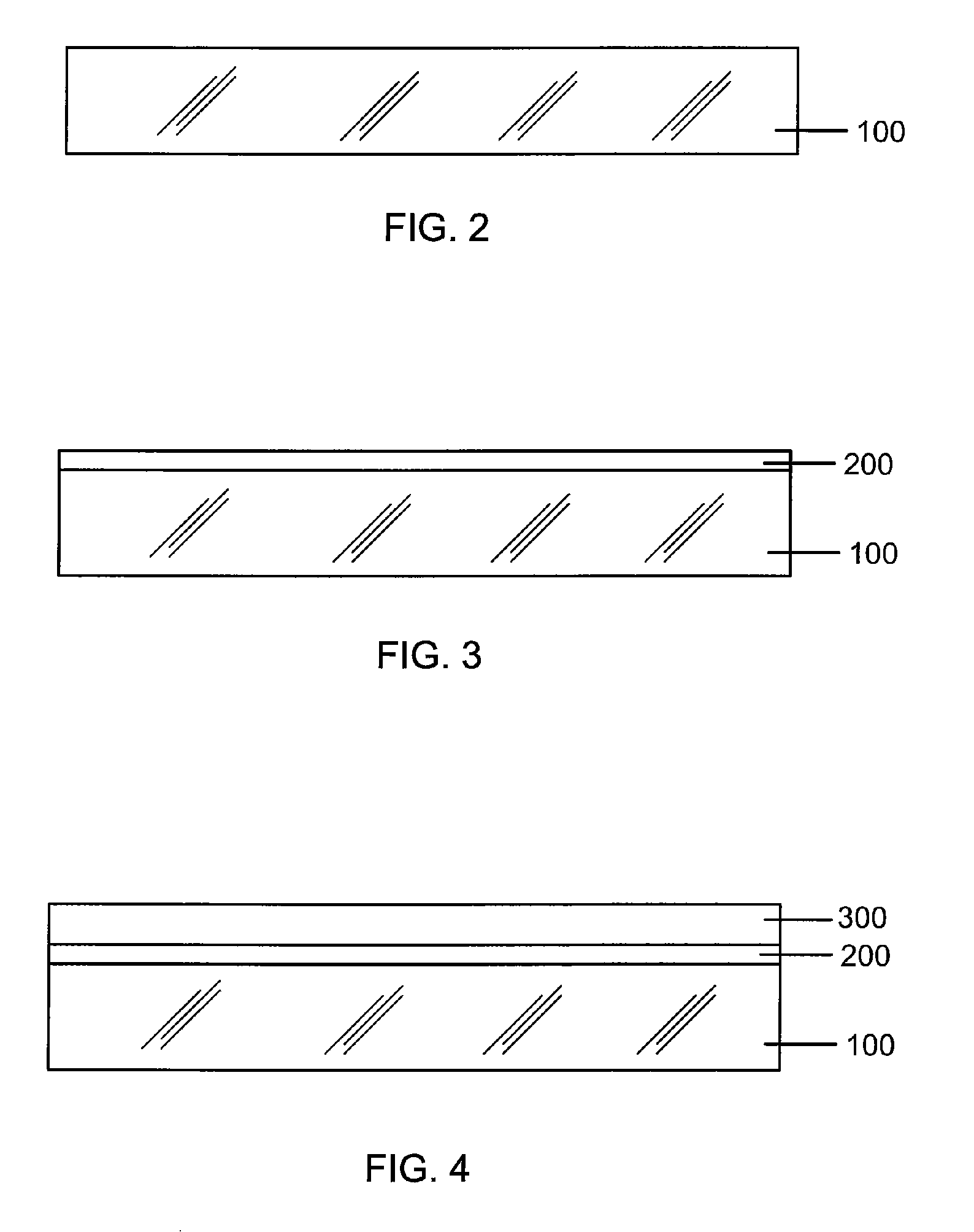

Sodium doping method and system of cigs based materials using large scale batch processing

InactiveUS20110020978A1Simple processImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyBatch processing

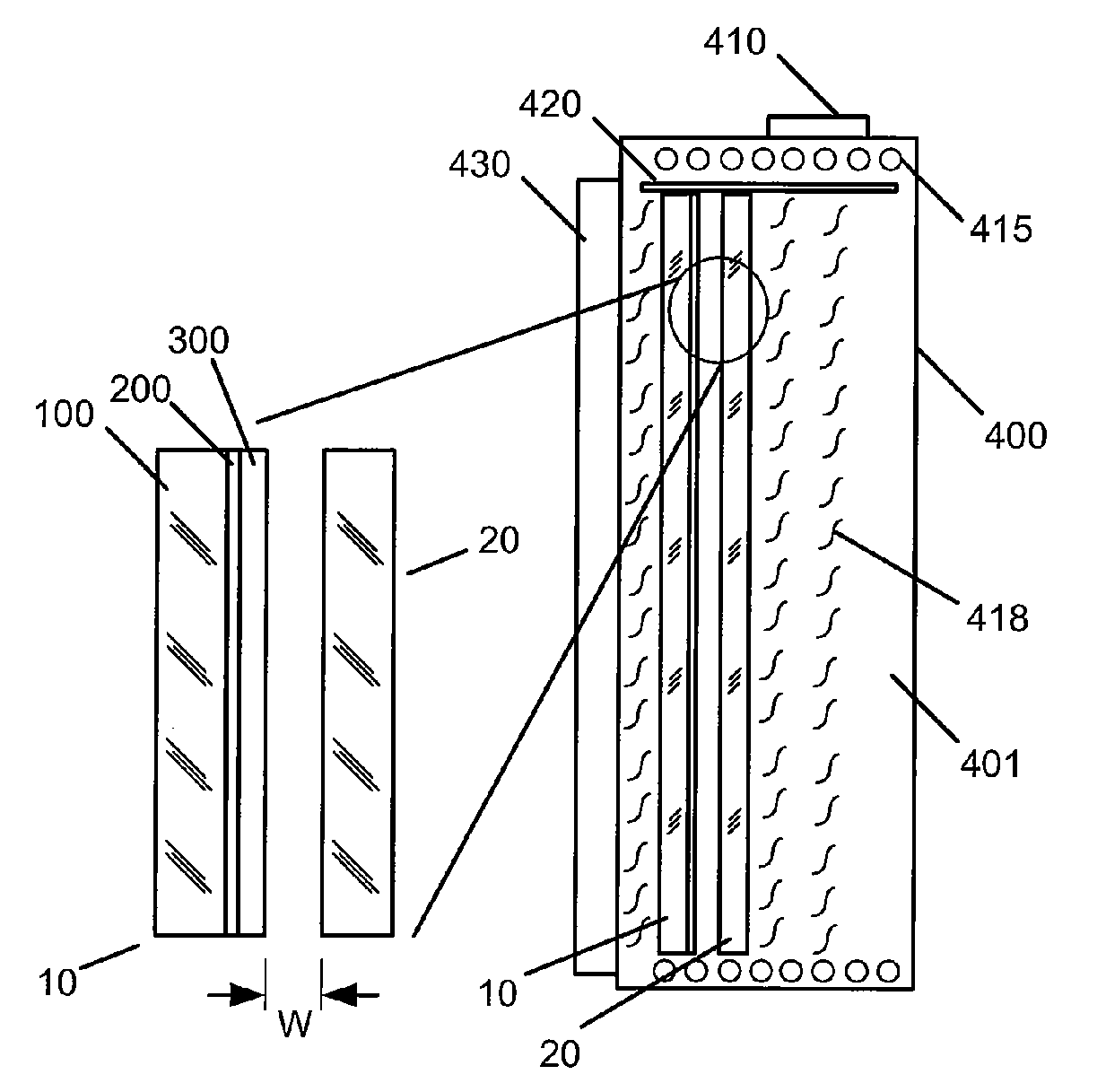

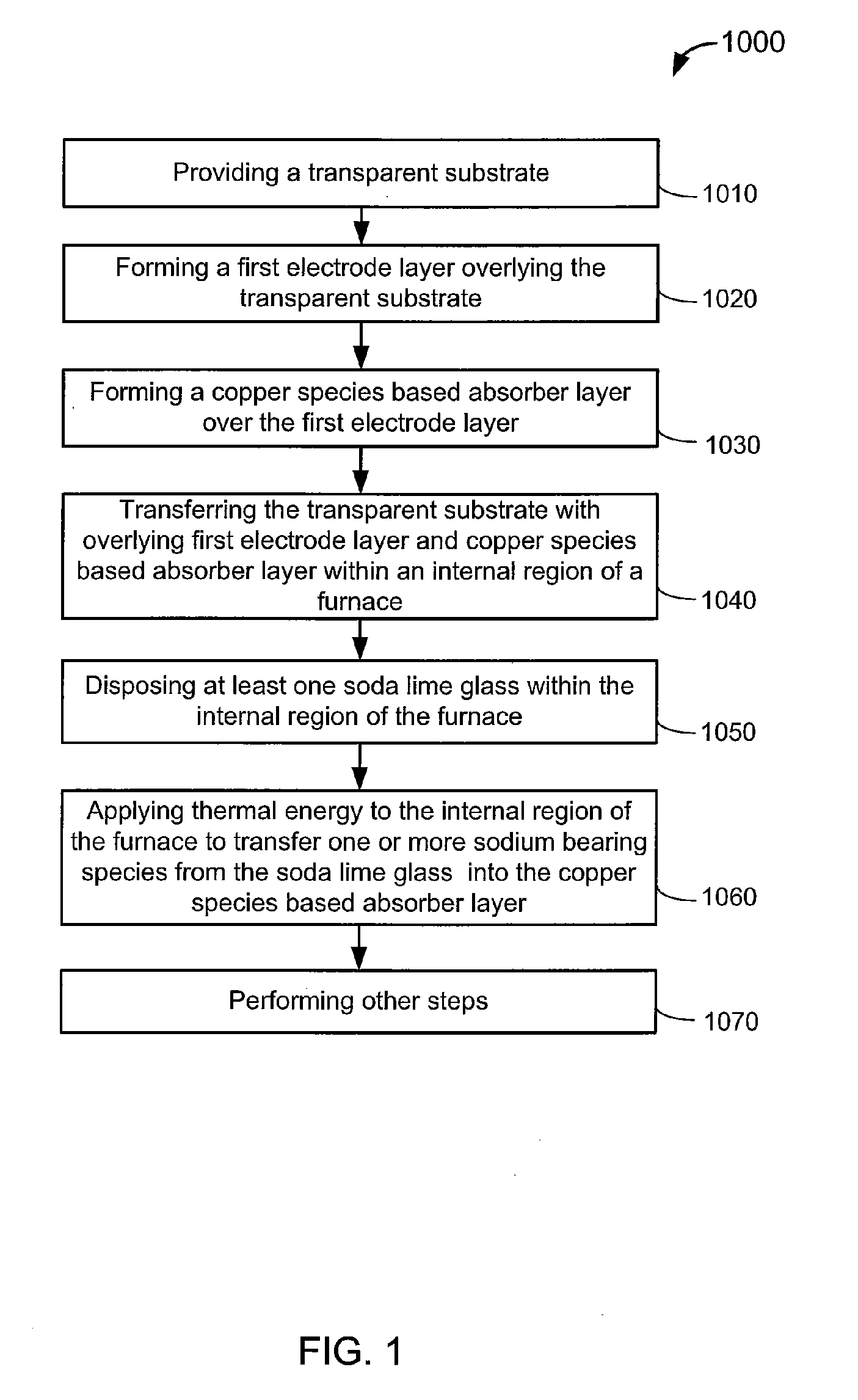

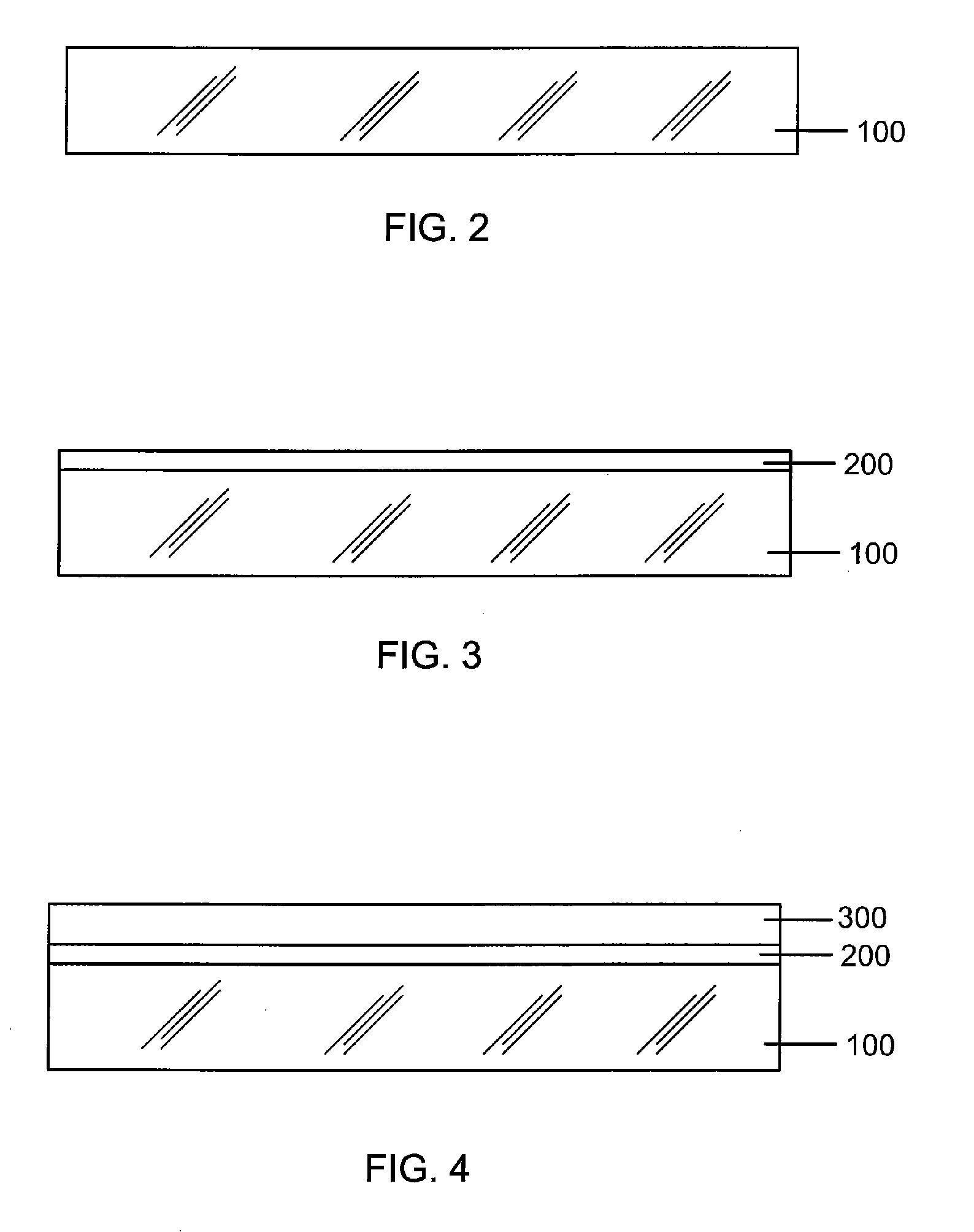

A method of processing a plurality of photovoltaic materials in a batch process includes providing at least one transparent substrate having an overlying first electrode layer and an overlying copper species based absorber precursor layer within an internal region of a furnace. The overlying copper species based absorber precursor layer has an exposed face. The method further includes disposing at least one soda lime glass comprising a soda lime glass face within the internal region of the furnace such that the soda lime glass face is adjacent by a spacing to the exposed face of the at least one transparent substrate. Furthermore, the method includes subjecting the at least one transparent substrate and the one soda lime glass to thermal energy to transfer one or more sodium bearing species from the soda lime glass face across the spacing into the copper species based absorber precursor layer via the exposed face.

Owner:CM MFG

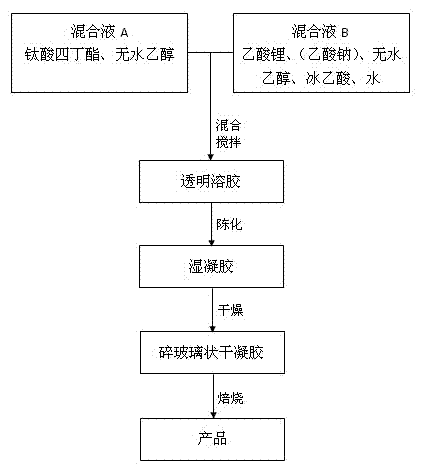

Novel carbon dioxide adsorbent and preparation method thereof

The invention discloses a novel carbon dioxide adsorbent and a preparation method thereof. The novel carbon dioxide adsorbent adopts lithium metatitanate with the chemical formula Li2TiO3 or sodium-doped lithium metatitanate with the chemical formula Li2(1-x)Na2xTiO3 to adsorb carbon dioxide at the high temperature of 500 to 700 DEG C. The lithium metatitanate is prepared by synthesizing raw materials comprising tetrabutyl titanate, lithium acetate, absolute ethanol, glacial acetic acid and water by an alkoxide hydrolysis sol-gel method; then the sodium-doped lithium metatitanate Li2(1-x)Na2xTiO3 is prepared by adding sodium acetate. When the temperature is above 500 DEG C, the adsorbent starts to react with the carbon dioxide and adsorption is performed; when the temperature is above 700 DEG C, reaction is performed reversely, carbon dioxide gas is released and the adsorbent is regenerated. The carbon dioxide of high-temperature flue gas can be adsorbed; the process is simple and convenient; products are easy to separate; materials are easy to regenerate and can be recycled. The preparation method provided by the invention is stronger in system chemical uniformity; the reaction process is easy to control; the calcinations molding temperature is low and requirements on equipment are low; modification is facilitated; components are uniform and have high purity.

Owner:EAST CHINA UNIV OF TECH

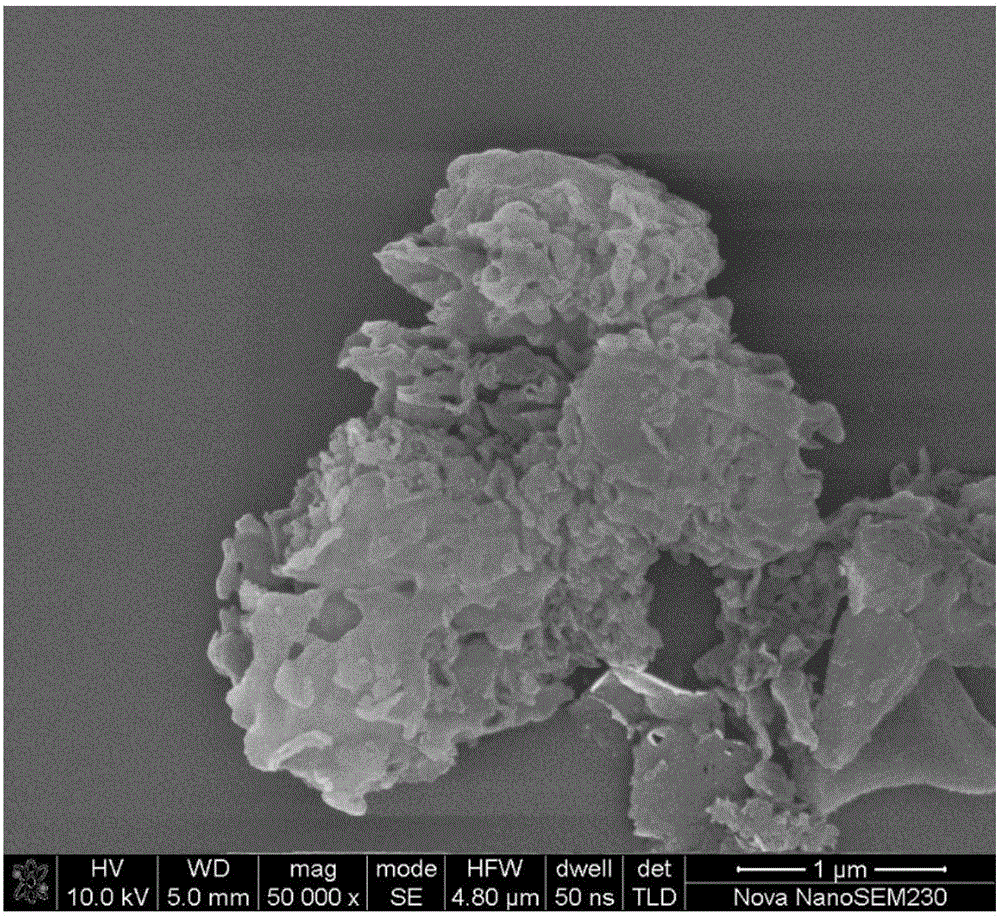

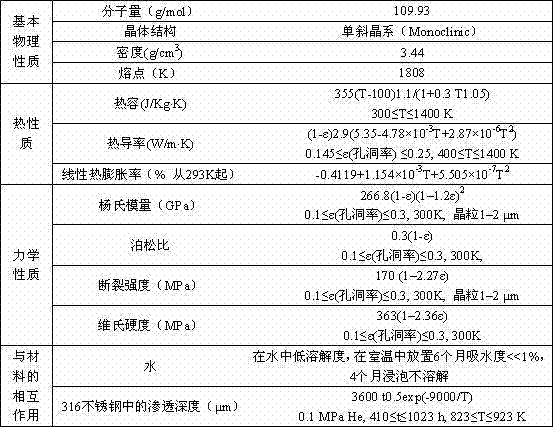

Preparation method of sodium-doped molybdenum plane sputtering target material

ActiveCN103160791AImprove conversion efficiencyReduce manufacturing costVacuum evaporation coatingSputtering coatingSputteringIndium

The invention provides a sodium-doped molybdenum plane sputtering target material. The sodium-doped molybdenum plane sputtering target material comprises molybdenum and sodium, wherein molybdenum atoms account for 90-99%, and the remaining is sodium atoms. The invention further provides a preparation method of the sodium-doped molybdenum plane sputtering target material. The sodium-doped molybdenum plane sputtering target material provided by the invention can greatly improve the conversion efficiency of a copper indium gallium selenium thin film battery, reduce production cost and realize large-scale industrialization of the copper indium gallium selenium thin film batteries by doping a sodium element in a molybdenum back electrode. According to the preparation method, molybdenum trioxide, sodium hydroxide and the molybdenum metal are taken as raw materials, and the sodium-doped molybdenum plane sputtering target material is prepared through reaction, ball milling, screening, hot pressing and other processes; the preparation method has the advantages of simple processes and low cost and is suitable for industrial production; and as for the prepared target material, the relative density is high and can be above 95%, the oxygen density is high and can achieve 250ppm, and the size is small and can achieve 60-100mu m.

Owner:亚芯半导体材料(江苏)有限公司 +1

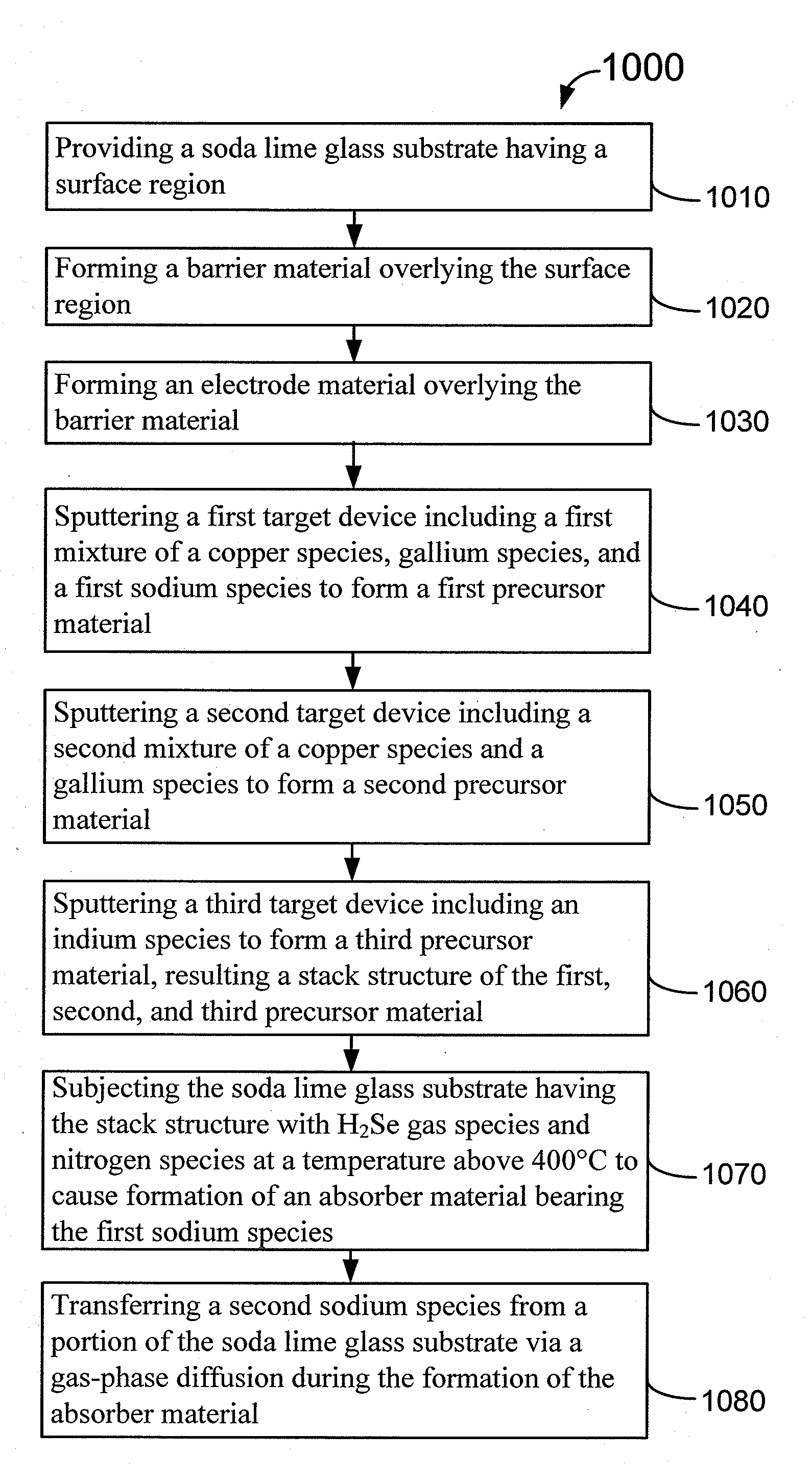

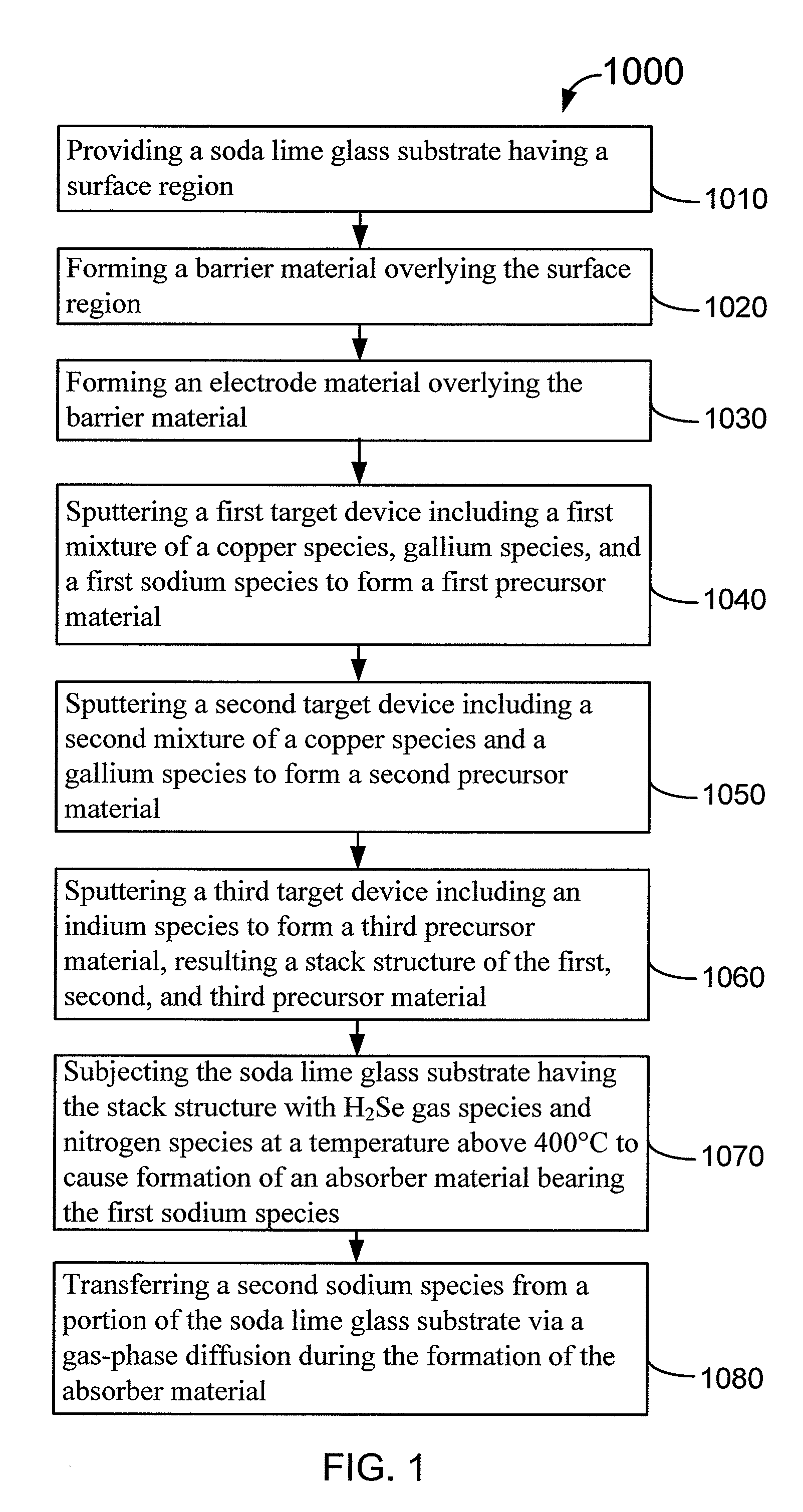

Method of Manufacture of Sodium Doped CIGS/CIGSS Absorber Layers for High Efficiency Photovoltaic Devices

InactiveUS20120302002A1Improve efficiencyImprove photovoltaic efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingThermal treatmentSoda-lime glass

A method for processing a thin-film absorber material with enhanced photovoltaic efficiency includes forming a barrier layer on a soda lime glass substrate followed by formation of a stack structure of precursor layers. The method further includes subjecting the soda-lime glass substrate with the stack structure to a thermal treatment process with at least H2Se gas species at a temperature above 400° C. to cause formation of an absorber material. By positioning the substrates close together, during the process sodium from an adjoining substrate in the furnace also is incorporated into the absorber layer.

Owner:CM MFG

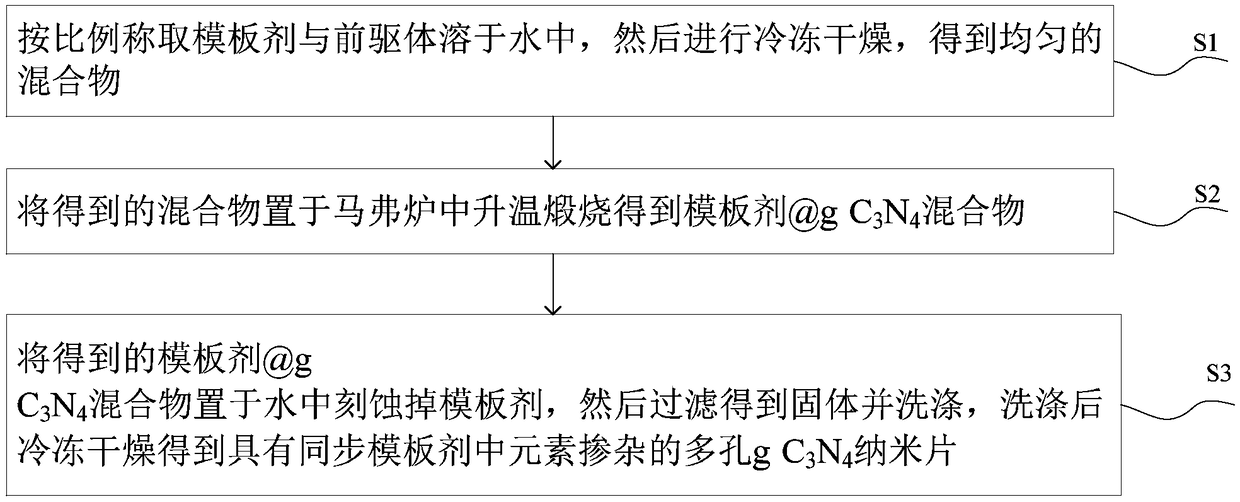

Preparation method of element-doped porous g-C3N4 nano-sheets

ActiveCN108855182ANo pollutionReduce manufacturing costPhysical/chemical process catalystsPhoto catalyticFiltration

The invention discloses a preparation method of element-doped porous g-C3N4 nano-sheets and relates to a green and environment-friendly preparation technology of sodium-doped porous graphite-phase carbon nitride (g-C3N4) nano-sheets. The preparation method comprises the following steps: after co-dissolving a template agent sodium chloride and a precursor dicyandiamide, freezing and drying; puttinga dried uniform mixture into a muffle furnace and carrying out high-temperature calcination under an air condition; putting a calcined sodium chloride@g-C3N4 mixture into de-ionized water and dissolving the sodium chloride; separating a sodium chloride template and the g-C3N4 by adopting a suction filtration manner; freezing and drying a light yellow solid substance obtained by suction filtrationto obtain the sodium-doped porous g-C3N4 nano-sheets; adding the dicyandiamide into filtrate again to prepare the sodium-doped porous g-C3N4 nano-sheets, so as to realize repeated utilization of thesodium chloride. The preparation method is simple and the cost of raw materials is low; the obtained sodium-doped porous g-C3N4 nano-sheets have the advantages of large specific surface area, strong light absorption capability and high photo-catalytic efficiency.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

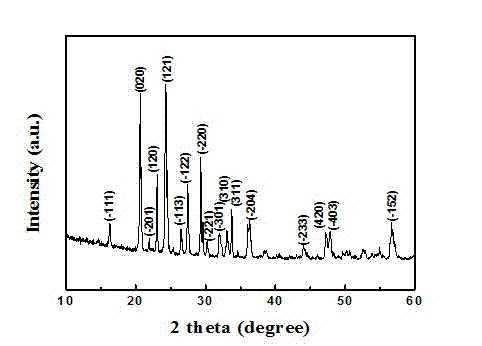

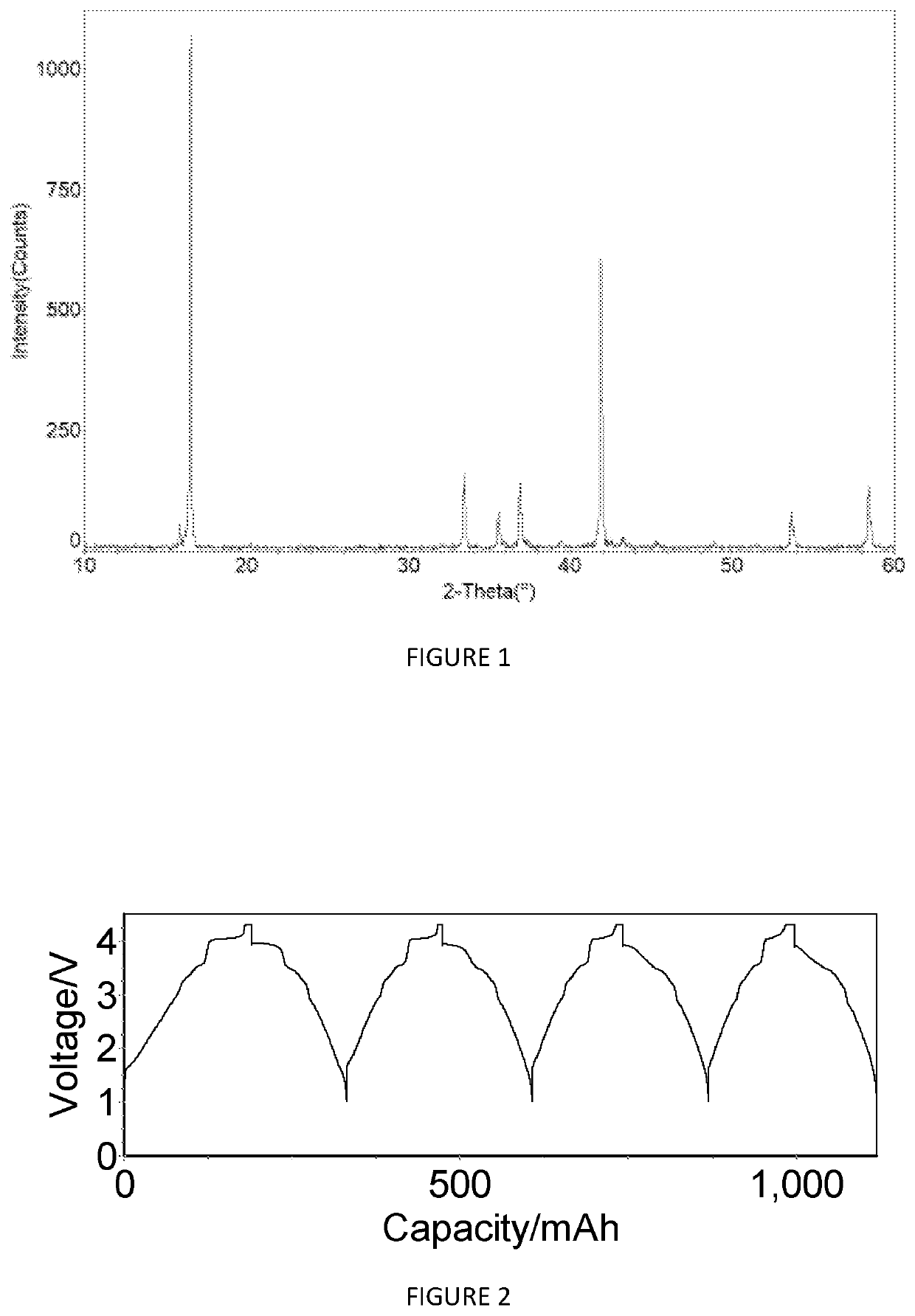

Rheological phase method for preparing sodium-doped positive pole material lithium vanadium phosphate of lithium-ion battery

InactiveCN102522564ASolve insufficient resourcesReduce demandCell electrodesPolyethylene glycolLithium-ion battery

The invention discloses a rheological phase method for preparing sodium-doped positive pole material lithium vanadium phosphate of a lithium-ion battery. The aqueous solution of hydrogen peroxide and vanadium pentoxide are mixed and react to obtain vanadium pentoxide hydrogel; and the vanadium pentoxide hydrogel, diammonium hydrogen phosphate, lithium hydroxide monohydrate, sodium salt and polyethylene glycol serve as raw materials to synthetize the precursor of the positive pole material Li3-xNaxV2(PO4)3 of the lithium-ion battery in one step. The precursor is calcinated under the protection of inert gas atmosphere, so that V5+ is fully reduced into V3+, and simultaneously a product Li3-xNaxV2(PO4)3 is generated. The rheological phase method for preparing the sodium-doped positive pole material lithium vanadium phosphate of the lithium-ion battery is simple and convenient, easy to control and low in cost; the synthesis process is simplified, the sodium-doped lithium vanadium phosphate Li3V2(PO4)3 has a larger lithium-ion transportation channel, and the conductivity of the Li3V2(PO4)3 can be improved, so that the charging, discharging and rate capability of a sample is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

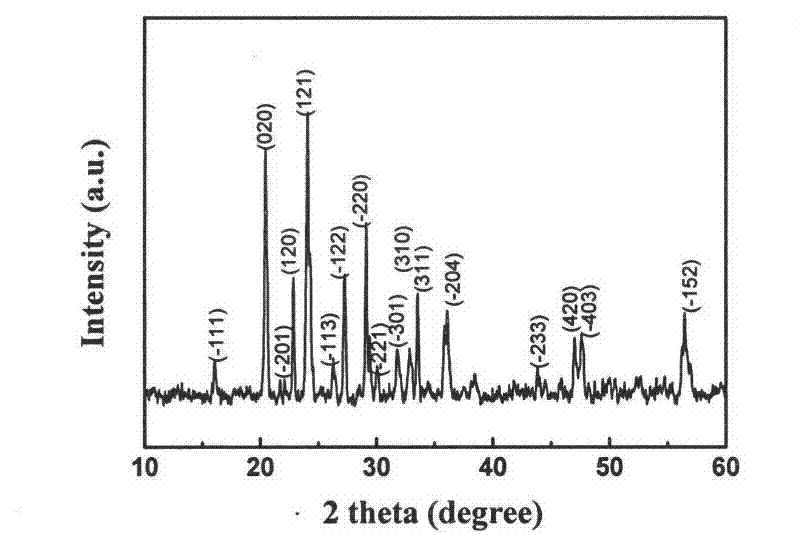

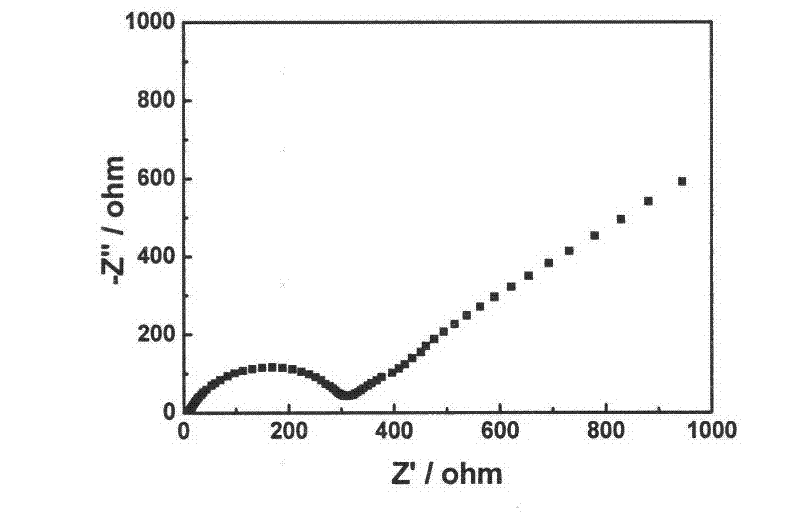

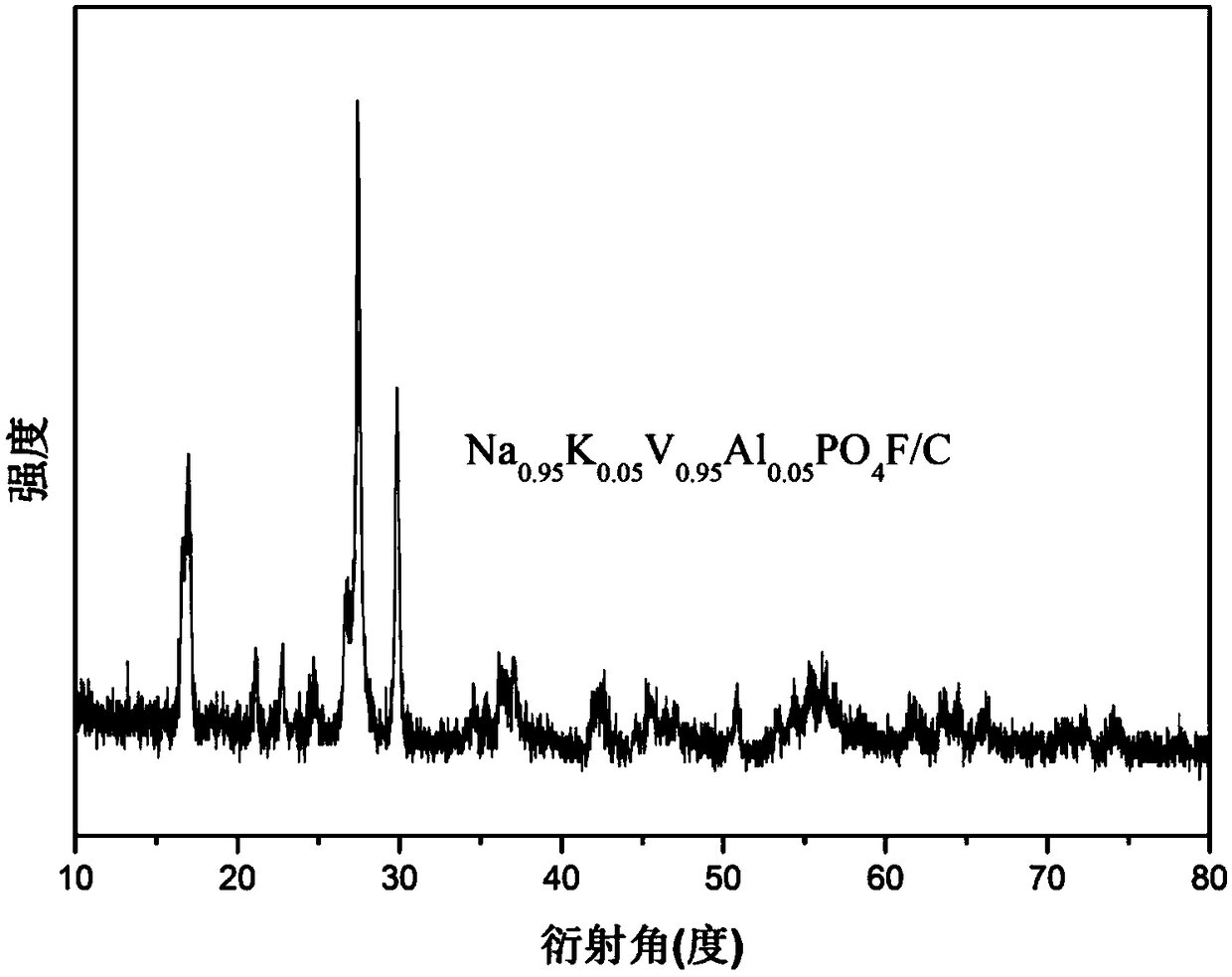

Preparation method of high-performance aluminum and potassium co-doped sodium vanadium fluorophosphates/carbon composite material

InactiveCN108417792AImprove electronic conductivityImproves sodium ion conductivityCell electrodesSecondary cellsCarbon compositesVanadium doping

The invention discloses a preparation method of a high-performance aluminum and potassium co-doped sodium vanadium fluorophosphate / carbon composite material. According to the preparation method, a uniform solution is formed from a reaction raw material and low-molecular polyethylene glycol, a high-activity aluminum-doped vanadium phosphate / carbon composite material is prepared by combining carbonthermal reduction reaction, and the high-performance Na<1-x>K<x>V<1-y>Al<y>PO<4>F / C composite material is obtained by high-temperature reaction under inert atmosphere by taking the aluminum-doped vanadium phosphate / carbon composite material as the raw material. Carbon with high electron conductivity is generated from polyethylene glycol and a carbohydrate under a high-temperature inert atmospherecondition in an in-situ way, carbon can generate a reduction agent in carbon thermal reduction reaction, and growth and agglomeration of product particles also can be prevented; a larger passage is provided for sodium ion mobility by sodium doped with potassium, and the structural stability of sodium vanadium fluorophosphate is improved by vanadium doped with aluminum; and by combining the advantages of high electron conductivity, large sodium ion mobility passage and structural stability, the aluminum and potassium co-doped sodium vanadium fluorophosphates / carbon composite material has excellent electrochemical performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

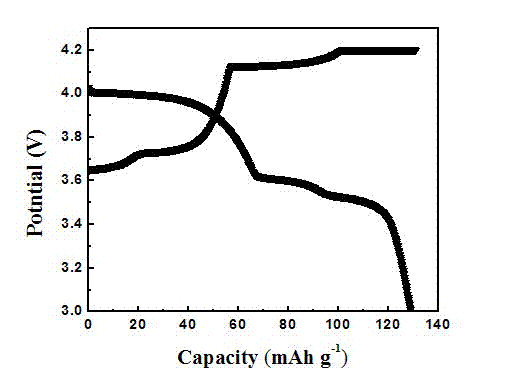

Method for preparing binary doped cathode material lithium vanadium phosphate of lithium ion battery

InactiveCN103094570ALower transfer resistanceReduce demandCell electrodesPolyethylene glycolSodium-ion battery

The invention discloses a method for preparing a binary doped cathode material lithium vanadium phosphate of a lithium ion battery. The method comprises the following steps of: mixing aqueous hydrogen peroxide solution and vanadium pentoxide to react to obtain vanadium pentoxide hydrogel; synthesizing a precursor of the cathode material Li3-xNaxV2(PO4-yFy)3 of the lithium ion battery by one step by using the vanadium pentoxide hydrogel, diammonium hydrogen phosphate, lithium hydroxide monohydrate, sodium salt, fluorine-containing salt and polyethylene glycol as raw materials; and roasting the precursor under the protection of inert gas to facilitate V<5+> to be completely reduced into V<3+> and generate the product Li3-xNaxV2(PO4-yFy)3. The method is simple and convenient, and has the characteristics of easy control and low cost; the synthesis process is simplified, sodium-doped Li3V2(PO4)3 has a larger lithium ion transportation channel, and the body conductivity of Li3V2(PO4)3 can be increased; and besides, by adding a little amount of fluorine, the polarization of the electrode can be reduced, the charge transfer resistance can be reduced, the diffusion rate of Li<+> can be increased, and the charging and discharging performance and the rate capability of the sample are improved finally.

Owner:JIANGXI YOULI NEW MATERIALS

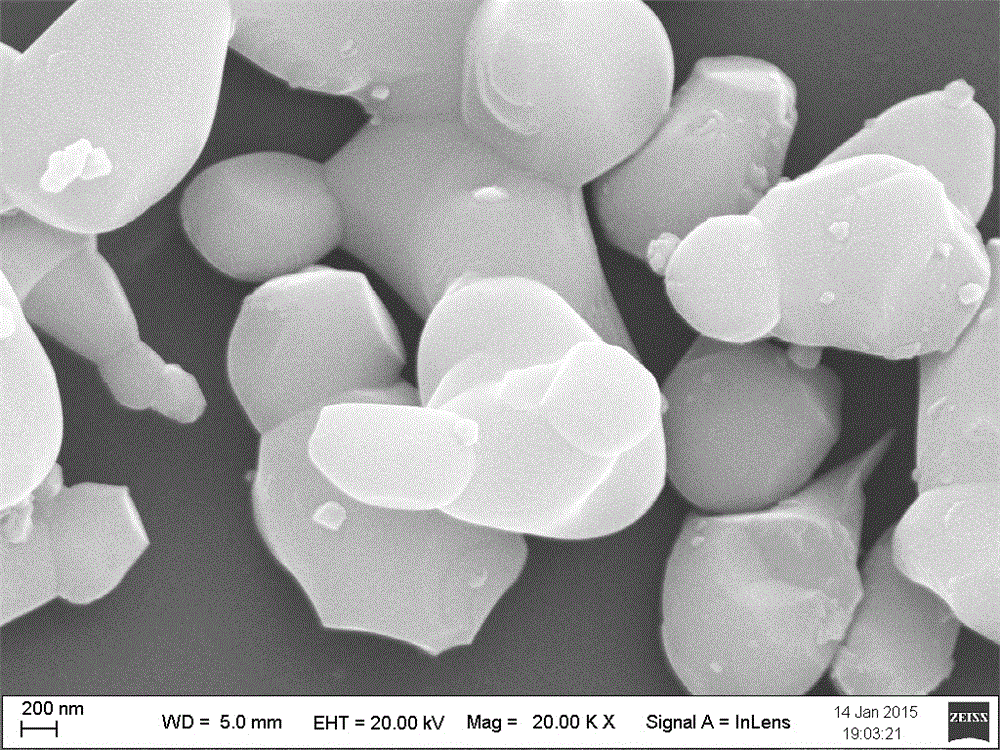

Sodium doped lithium-manganese-rich base positive material and preparation method and application thereof

InactiveCN107644992AAddress performance deficienciesImprove structural stabilityCell electrodesSecondary cellsLithiumManganese

The invention discloses a sodium doped lithium-manganese-rich base positive material and a preparation method and application thereof. The positive material comprises sodium-doped lithium-manganese-rich base granules, wherein the chemical structural formula of the sodium-doped lithium-manganese-rich base granules is: Li1+nNamNixC0yMn(1-x-y-n-m)O2, and 0 is smaller than or equal to n+m which is smaller than or equal to 1, 0 is smaller than or equal to x which is smaller than or equal to 1, and 0 is smaller than or equal to y which is smaller than or equal to 1. By the arrangement, even doping of sodium in a lithium bit is achieved through sodium doping, particle size is kept to be smaller than 500nm during preparation, and electrochemical performance of the lithium-manganese-rich base positive material is improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

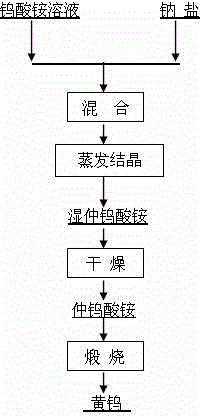

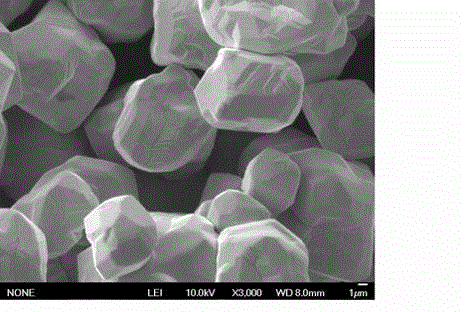

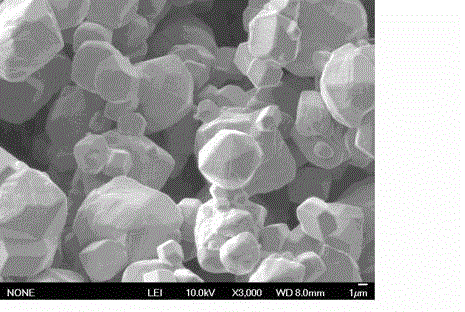

Preparation method of uniform sodium-doped ammonium paratungstate and/or yellow tungsten oxide

InactiveCN104445416ALow elemental contentSimple production processTungsten oxides/hydroxidesAmmonium paratungstateTungstate

The invention belongs to the technical field of tungsten smelting and in particular relates to a preparation method of uniform sodium-doped ammonium paratungstate and / or yellow tungsten oxide, which aims to solve the defect that the subsequent products are influenced by uneven growth of particles caused by the uneven distribution of sodium in the existing sodium doping process and the defects of the exiting sodium-containing WO3 production method. According to the preparation method of uniform sodium-doped ammonium paratungstate and / or yellow tungsten oxide, the sodium is doped under the strong base condition; the ammonia concentration does not need to be adjusted; the content of impurity elements in the raw material which is an ammonium tungstate solution is low; no impurity harmful to the subsequent processes is introduced into the doping raw material; the solution does not need to be washed by other substances, is directly extracted when the solution arrives at a crystallization final point, and does not need to be washed by water; the product is uniformly doped with sodium. The crystallization mother solution is small in quantity and easy to recycle and use; the doping process is few and simple to operate; sodium-containing compounds suitable for the sodium-doping process are various in types; the sodium-doped APT and yellow tungsten oxide powder prepared by the method are high in Fsss particle size; the sodium elements are uniformly distributed; the crystalline form is complete.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

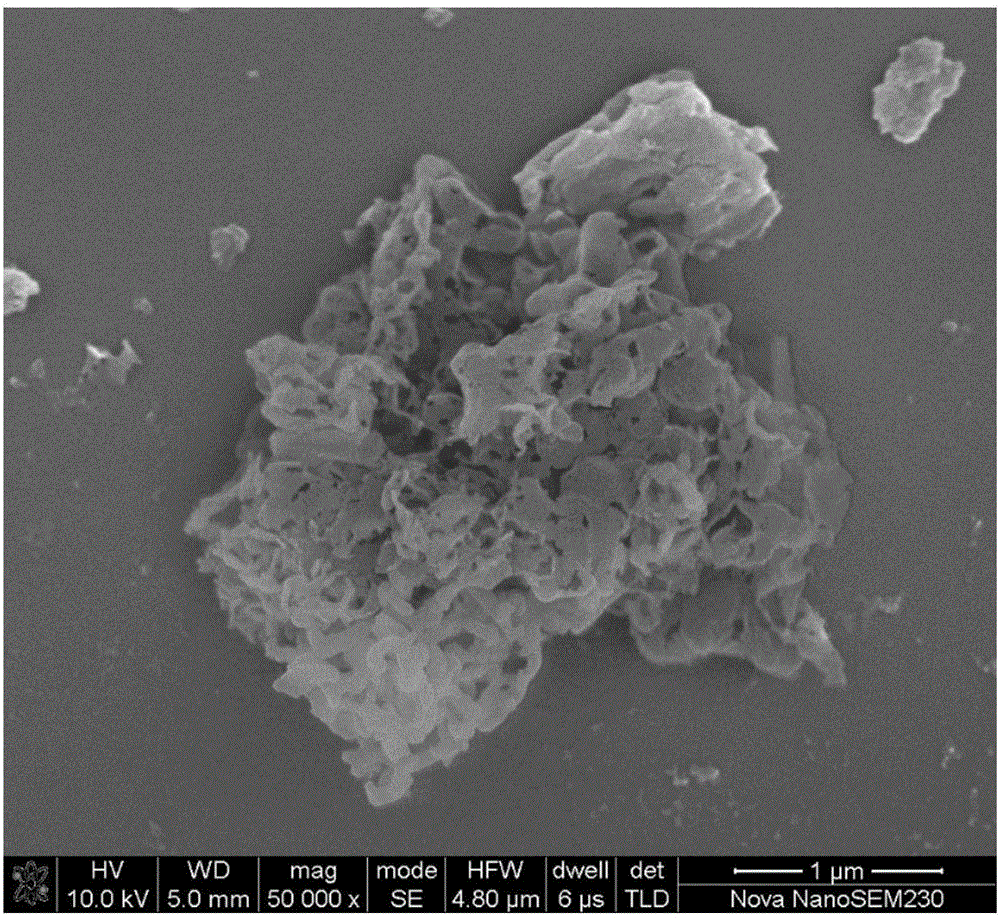

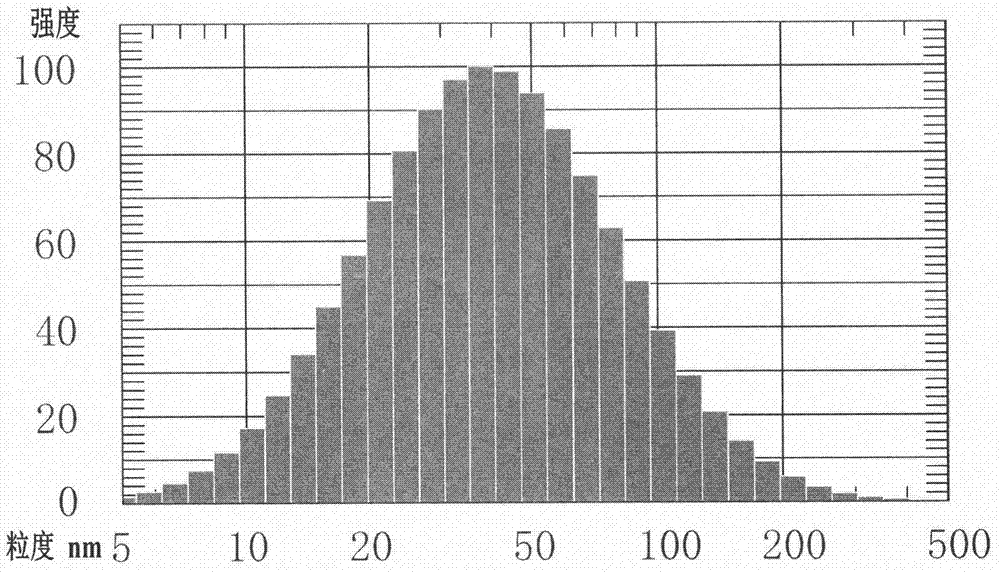

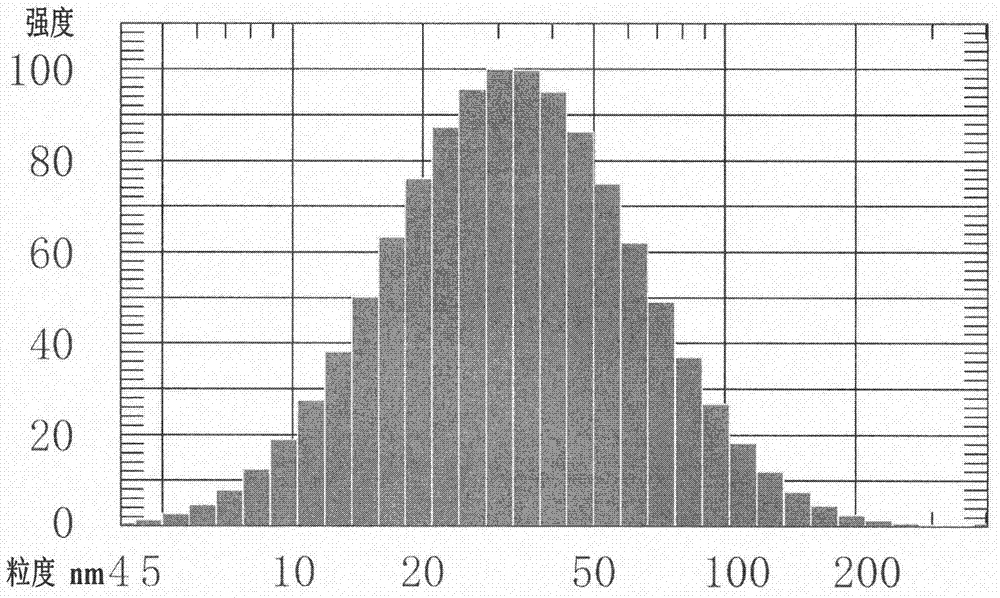

Method for preparing sodium-doped blue tungsten oxide nano-powder and dispersion liquid thereof

InactiveCN107512737AImprove uniformityImprove particle agglomerationMaterial nanotechnologyTungsten oxides/hydroxidesHydrolysisBall mill

The invention provides a method for preparing sodium-doped blue tungsten oxide nano-powder for infrared blockage and dispersion liquid of the nano-powder. The nano-powder is a hydrolysis product obtained by covering the surface of sodium nitrate with a layer of tungsten compound through the microsolubility of sodium nitrate in an alcohol system and the alcoholysis property of the tungsten compound by virtue of an in-situ hydrolysis coating technique. The method comprises the following steps: carrying out batching according to a molar ratio that Na / W is equal to 0.1-1, adding the materials into alcohol mixed with an alcoholysis inhibitor, slowly stirring, putting the material into a planetary ball mill, grinding, taking out, and drying so as to obtain a solid-phase precursor; and finally, roasting the obtained solid-phase precursor in a hydrogen argon reduction atmosphere at 400-650 DEG C for 2-10 hours, so as to obtain the sodium-doped blue tungsten oxide nano-powder. Based on the preparation of the nano-powder, sodium-doped blue tungsten oxide nano-dispersion liquid with a solid content of 10%-60% is prepared from sodium-doped blue tungsten oxide by virtue of a nano-grinding technique. The nano-powder or the dispersion liquid can be applied to the fields of heat-insulating films of electronic parts and components, buildings or vehicle windows and the like and has a good infrared blockage effect.

Owner:张春明

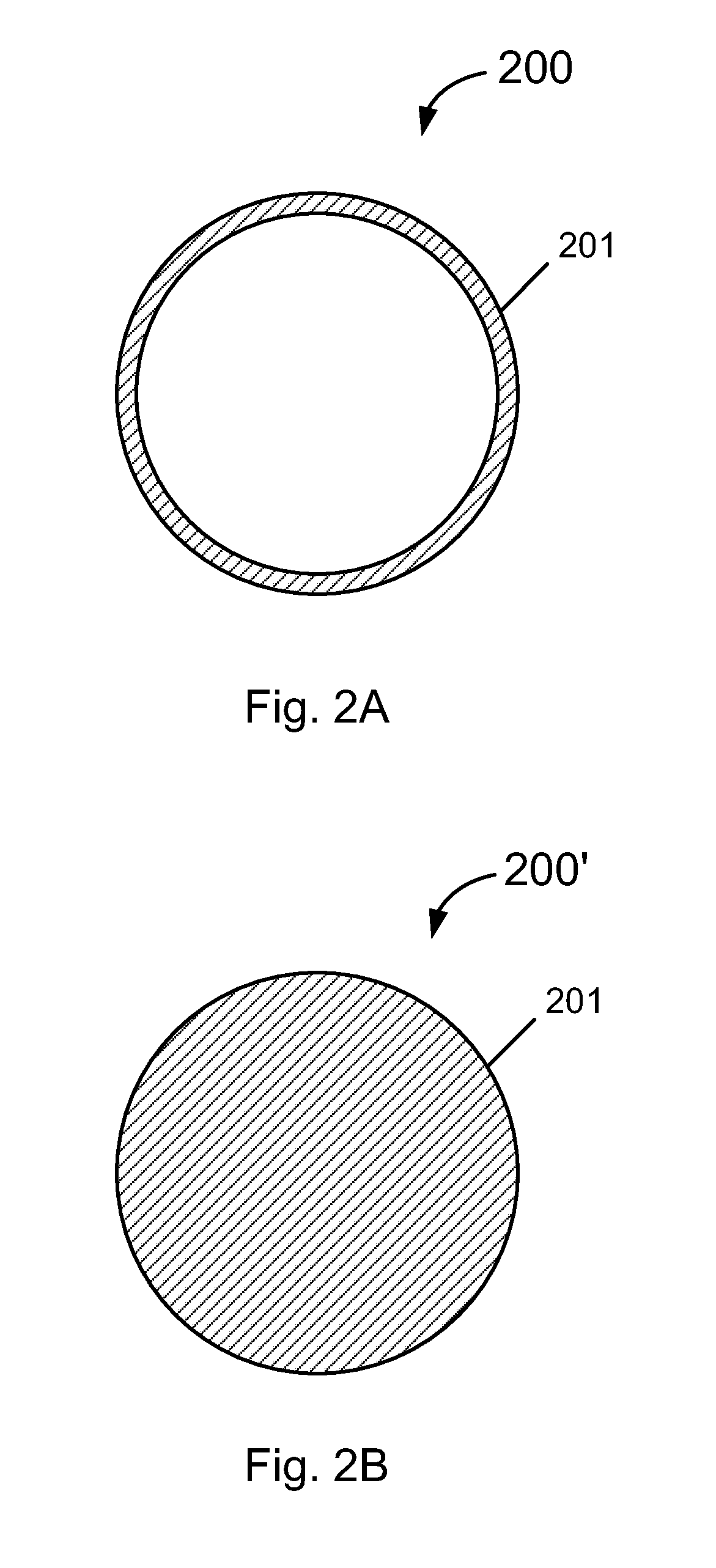

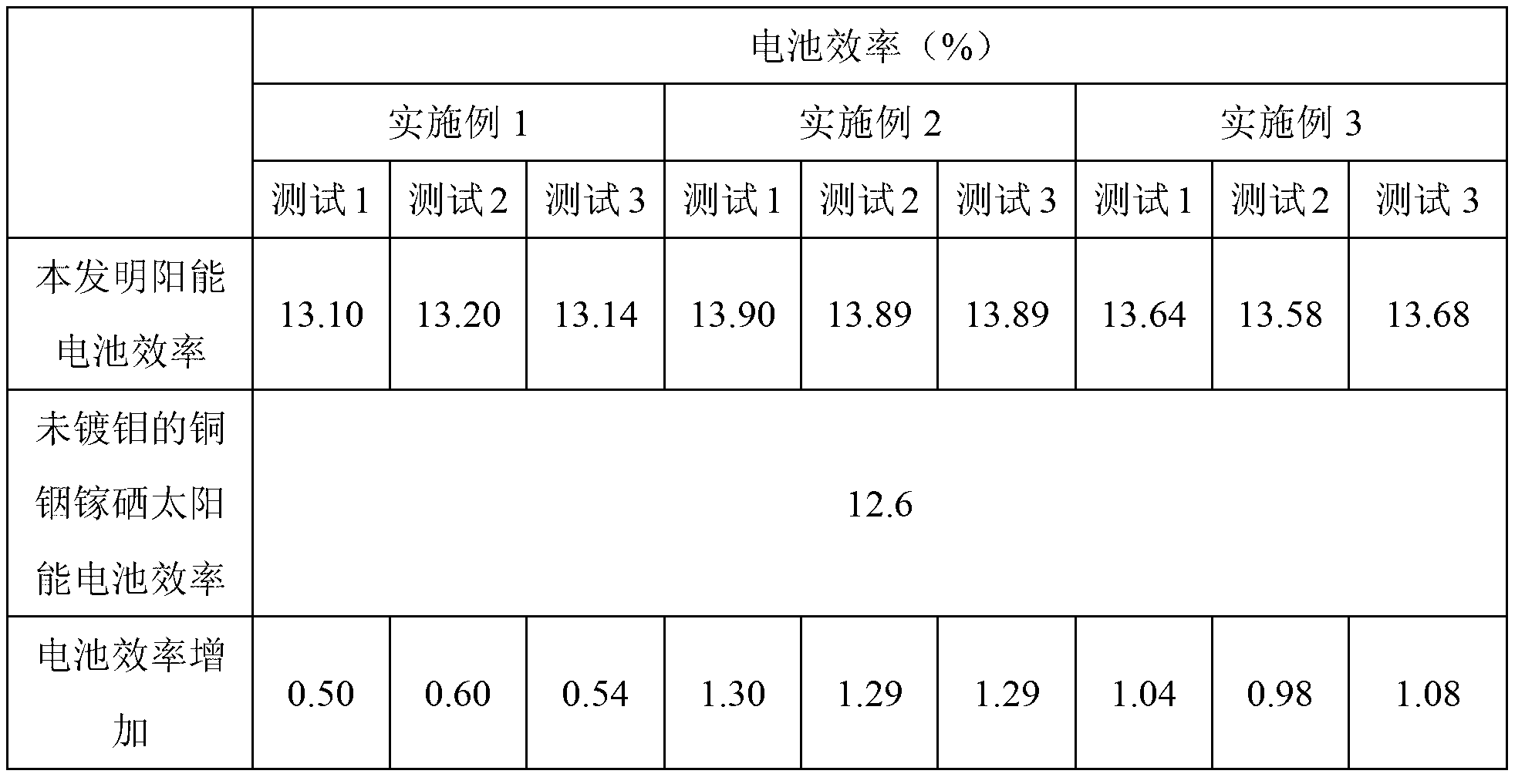

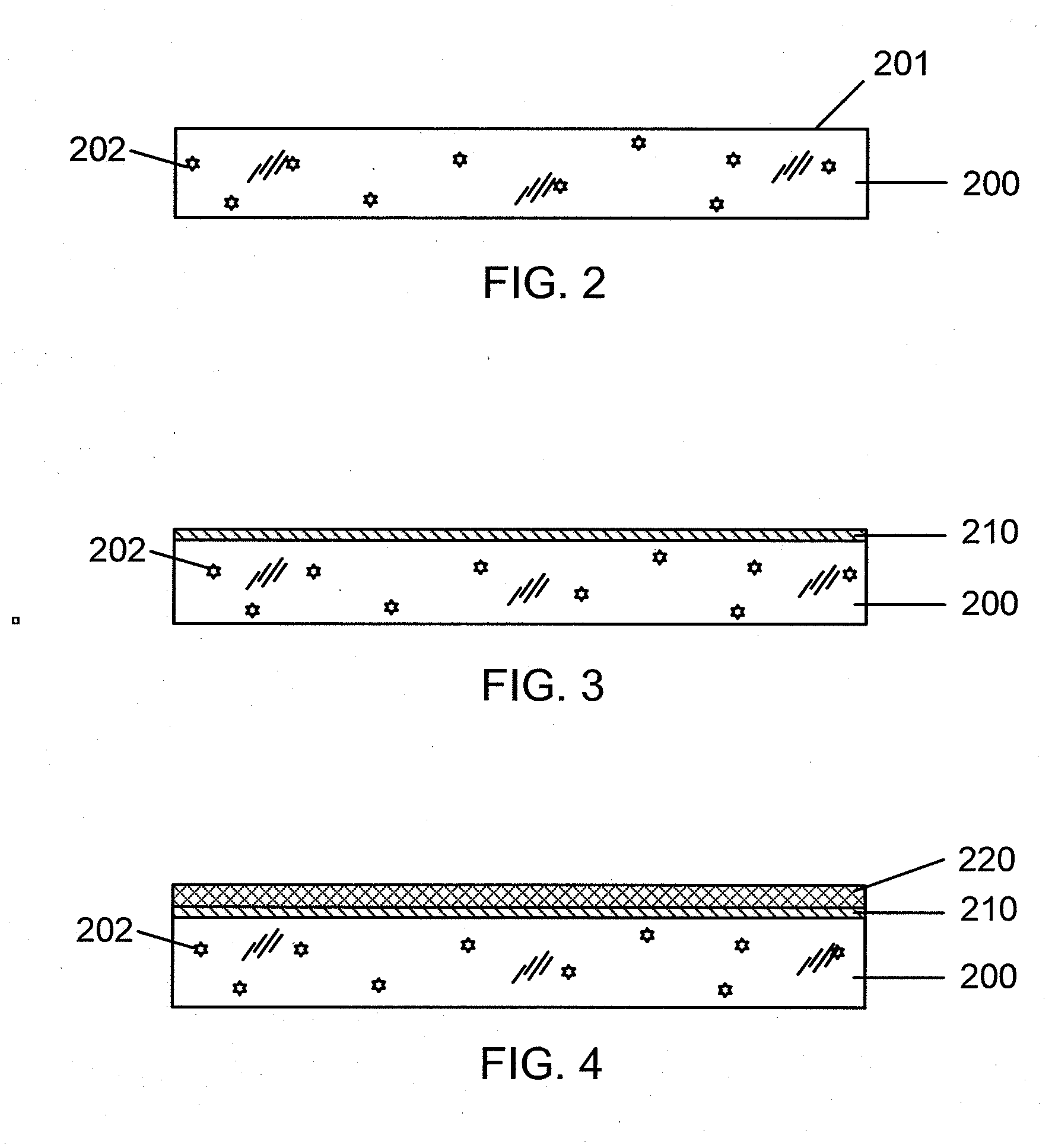

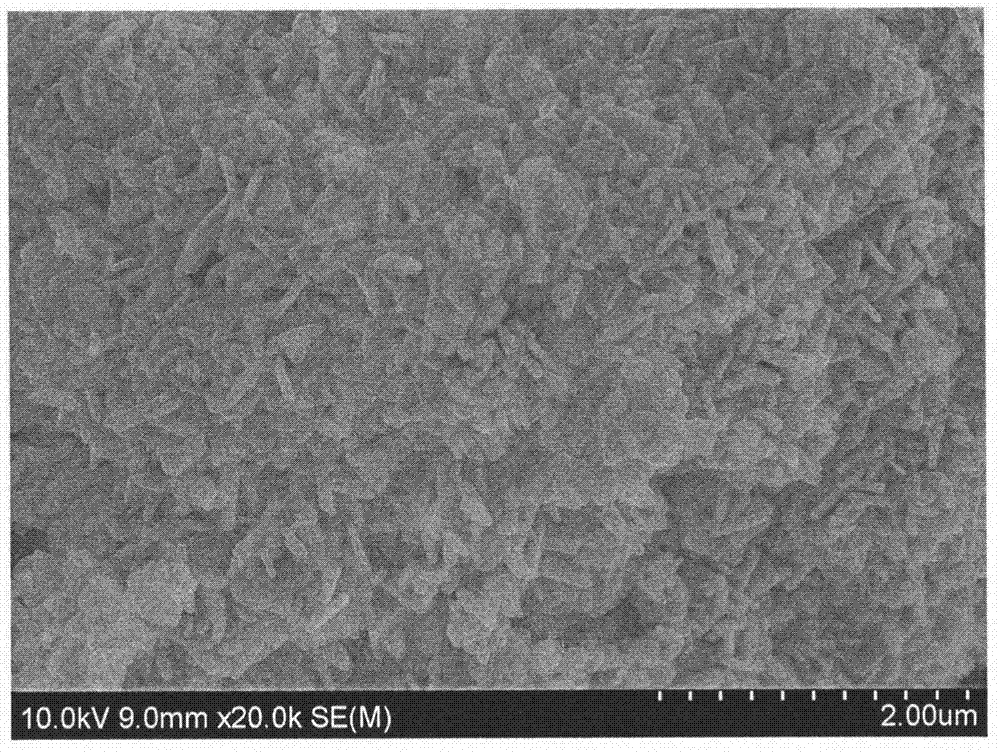

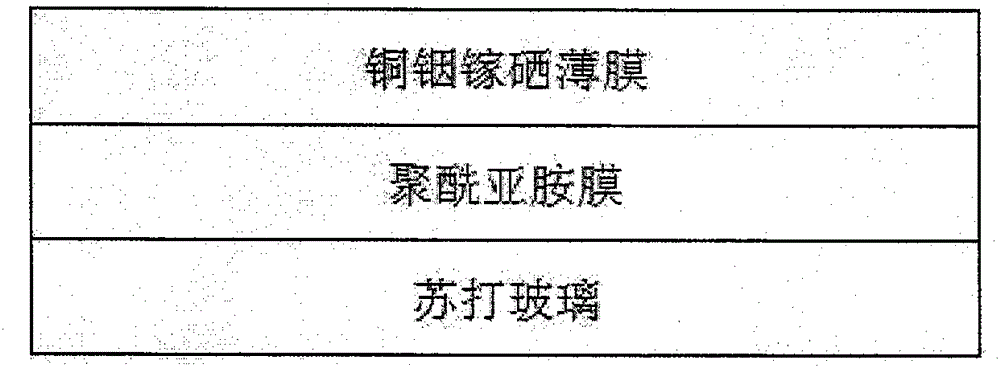

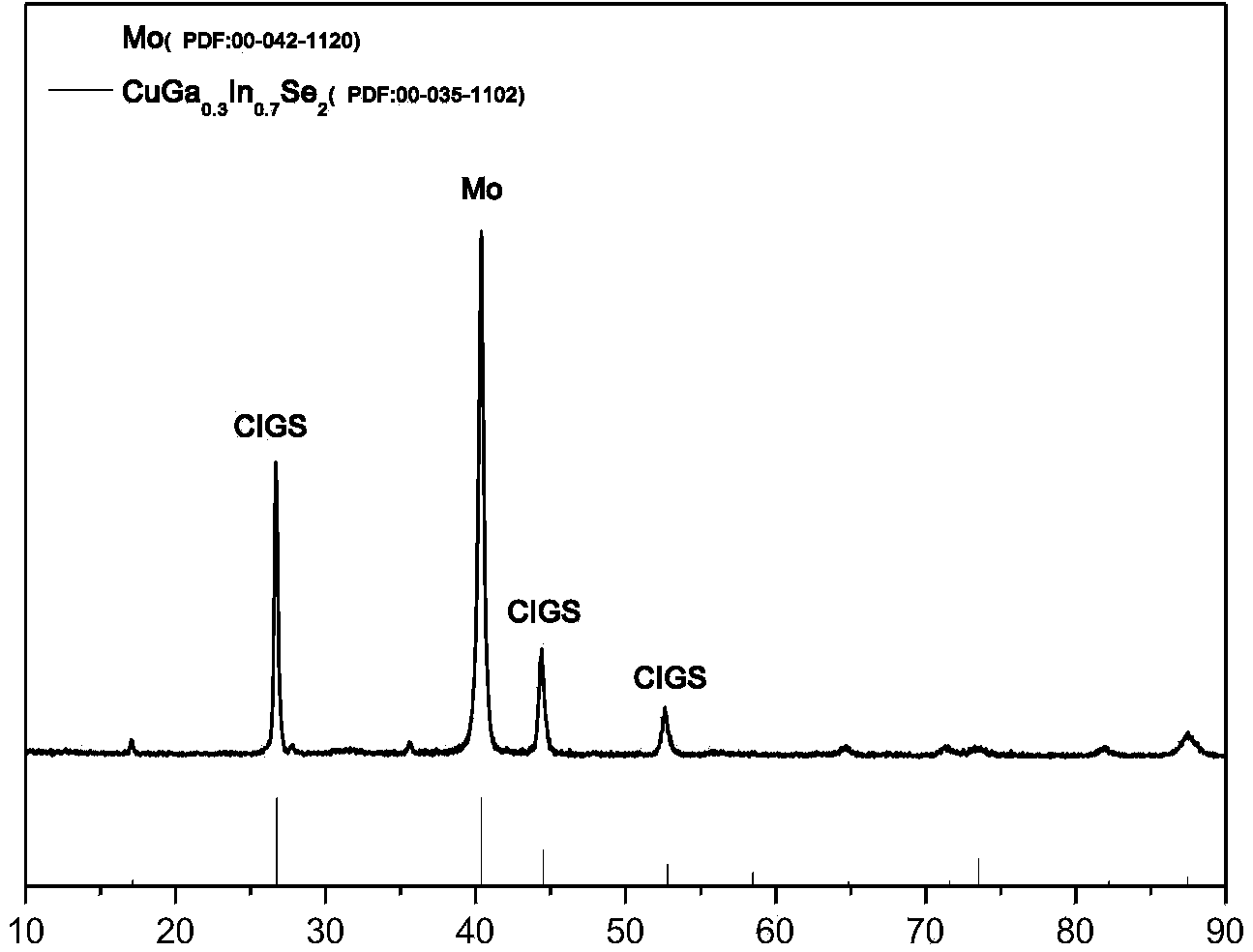

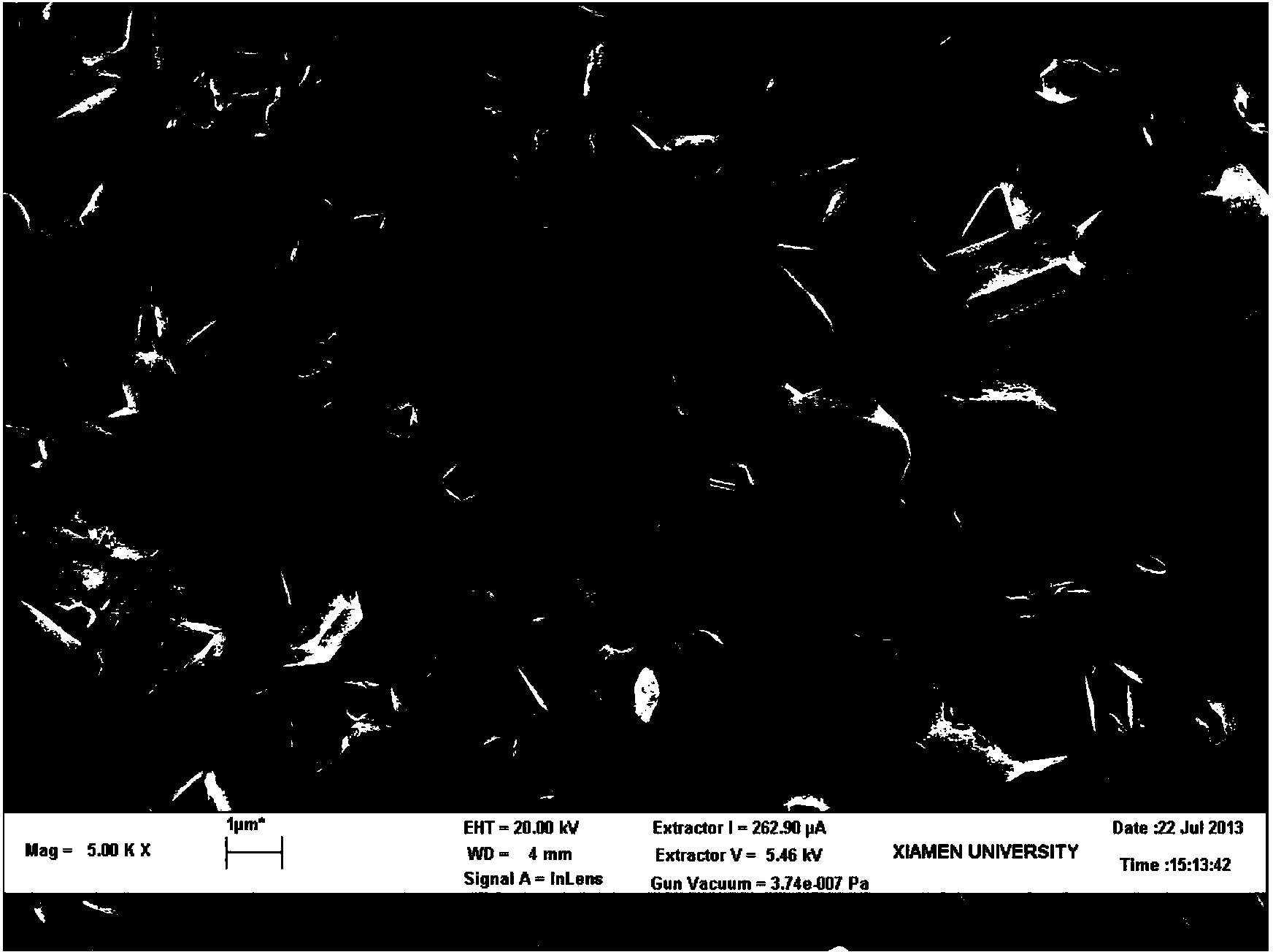

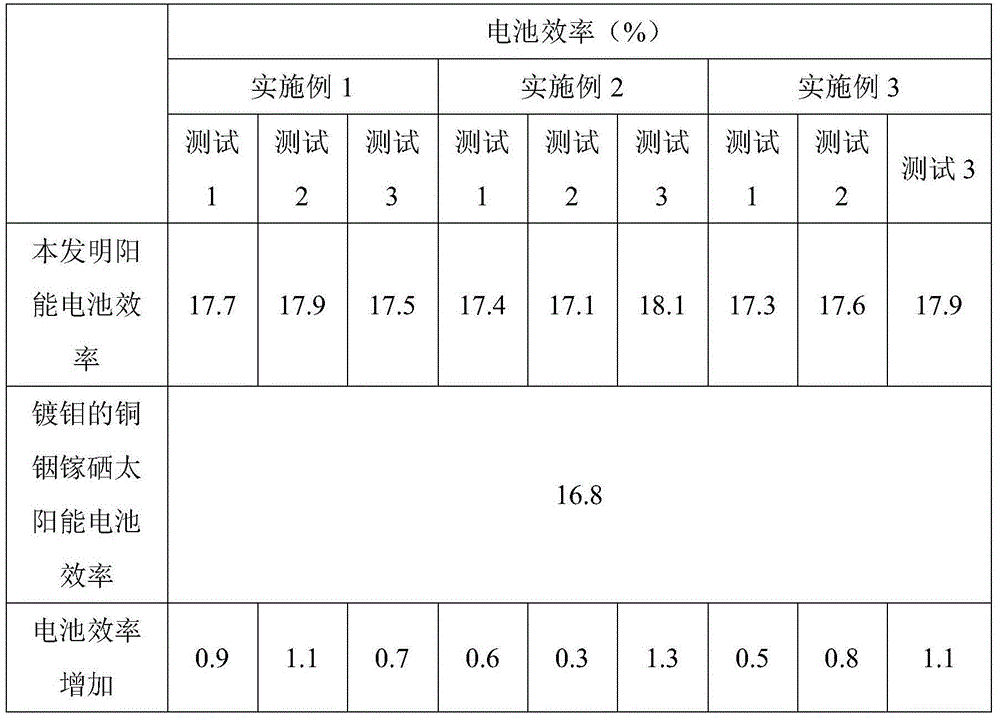

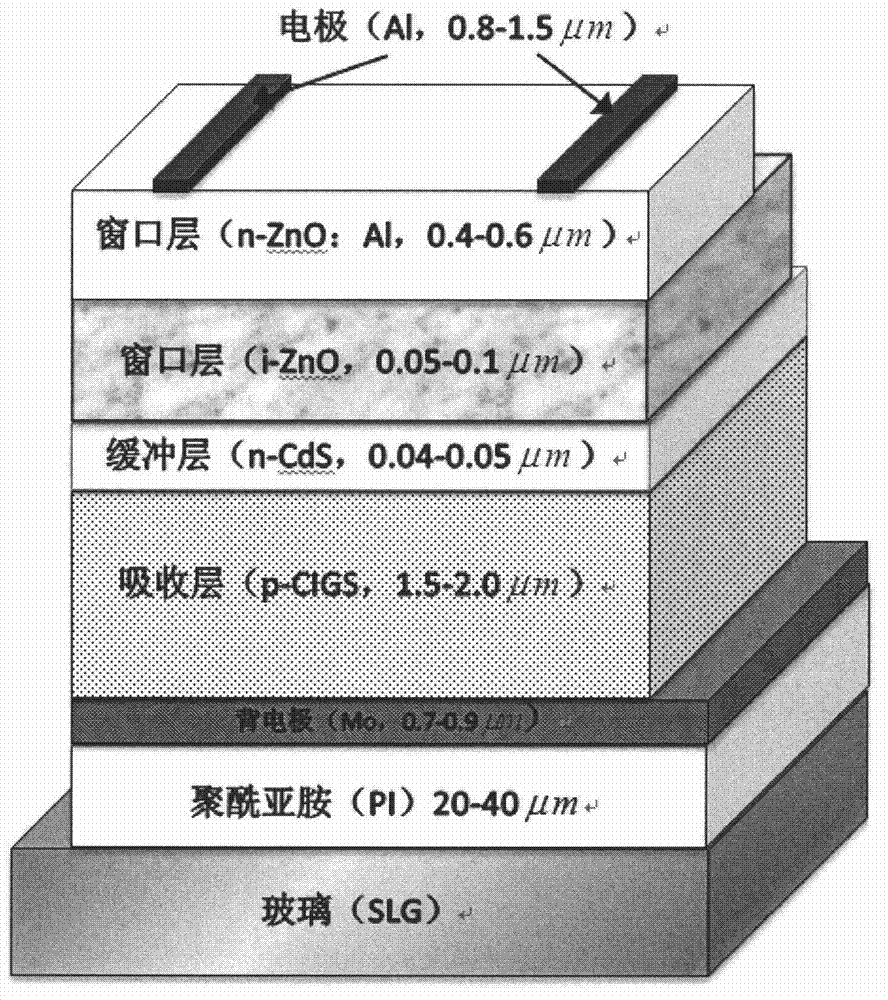

Sodium-doped CIGS (copper indium gallium selenide) film based on composite substrate and preparation method thereof

The invention provides a sodium-doped CIGS (copper indium gallium selenide) film based on a composite substrate and a preparation method thereof. The substrate is composed of soda glass and a polyimide film grown on the surface of the soda glass, the thickness of the soda glass is in the range of 1.5-2mm, the thickness of the polyimide film is in the range of 25-30[mu]m, the chemical formula of a CIGS film grown on the surface of the composite substrate is CuIn<1-x>Ga<x>Se<2>, x represents 0.25-0.35, and the conduction is in a p type, the CIGS film CuIn<1-x>Ga<x>Se<2> is arranged on the surface of the polyimide film-soda glass composite substrate by means of thin-film deposition, and the thickness is in the range of 1.5-2[mu]m. The CIGS film based on the polyimide film-soda glass composite substrate is good in quality, large in crystal grain, and has fewer defects, a flexible solar cell is made by a rigid substrate, and the preparation method is simple and easy to implement, and is favorable for large-scale popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

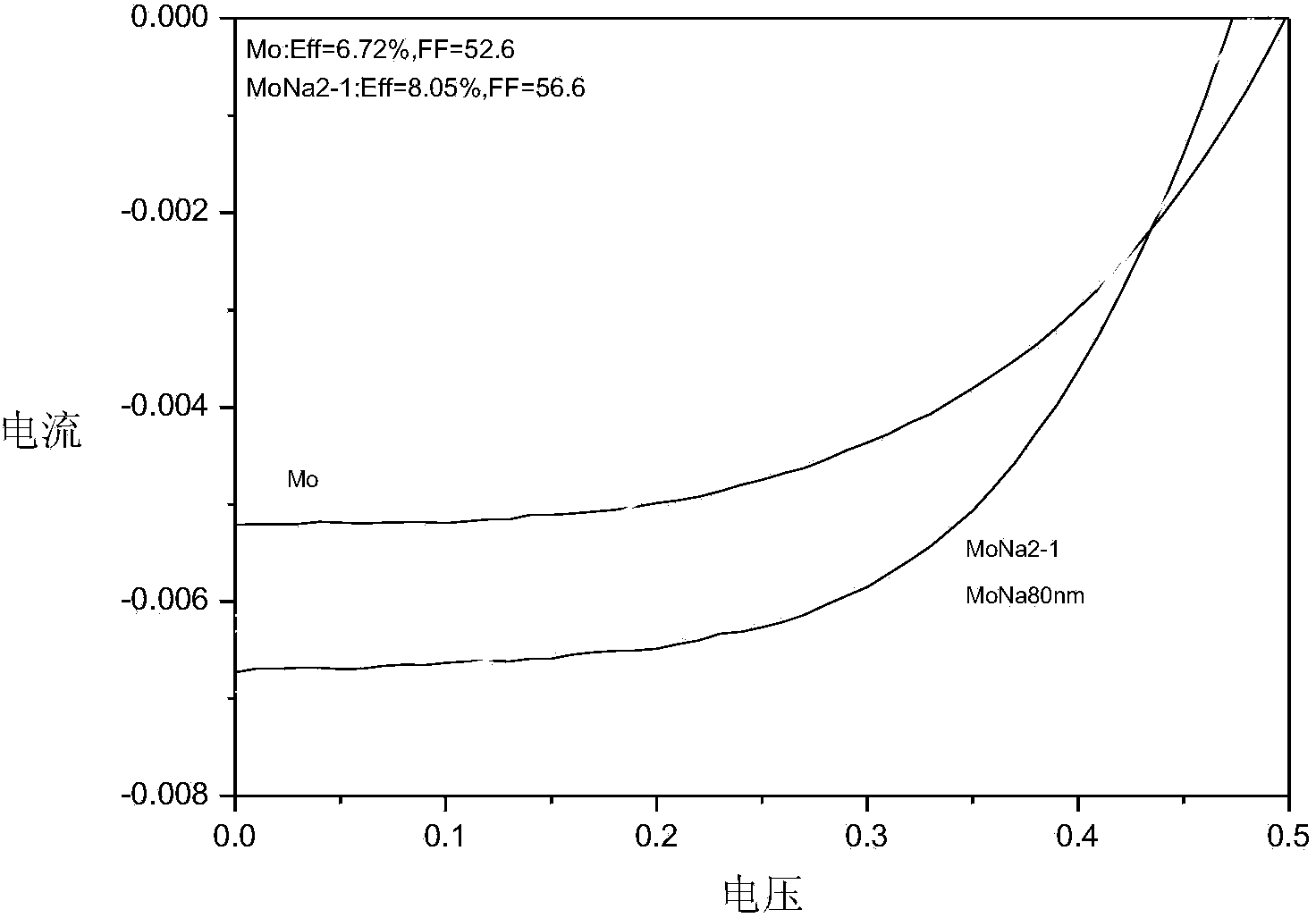

Molybdenum film containing sodium and preparation method and application thereof

InactiveCN103872154AMaximize positive impactFinal product manufactureSemiconductor/solid-state device manufacturingIndiumCopper indium gallium selenide

The invention discloses a molybdenum film containing sodium and a preparation method and application of the molybdenum film containing sodium. The molybdenum film containing sodium sequentially comprises a first pure-molybdenum layer, a molybdenum layer containing sodium, a second pure-molybdenum layer and a substrate from top to bottom, wherein the first pure-molybdenum layer is 10 nanometers to 1 micron thick, the molybdenum layer containing sodium is 10 nanometers to 1 micron thick, the second pure-molybdenum layer is 100 nanometers to 2 microns thick, the sodium content of the molybdenum layer containing sodium ranges from 1% [at] to 20% [at], the molybdenum content of the molybdenum layer containing sodium ranges from 80% [at] to 99% [at], and the molybdenum content of each pure-molybdenum layer ranges from 99.9% [at] to 99.9999% [at]. Compared with the prior art, the adhesion, the electrical conductivity and other respects of the molybdenum film containing sodium meet the requirements of a copper indium gallium selenide film solar cell, and the molybdenum film containing sodium can be used for manufacturing of the high-quality copper indium gallium selenide film solar cell. By the adoption of the preparation method of the molybdenum film containing sodium, the sodium-doped molybdenum film containing an appropriate amount of sodium can be prepared, and it is guaranteed that the positive influence of the doping amount of sodium on the efficiency of the copper indium gallium selenide film solar cell is maximized relatively. The prepared molybdenum film containing sodium is wide in application range and can be prepared based on common substrates of the copper indium gallium selenide film solar cell made of glass or PI or stainless steel or ceramic or the like.

Owner:XIAMEN UNIV

Method of manufacture of sodium doped CIGS/CIGSS absorber layers for high efficiency photovoltaic devices

InactiveUS8436445B2Improve efficiencyImprove photovoltaic efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingThermal treatmentSoda-lime glass

Owner:CM MFG

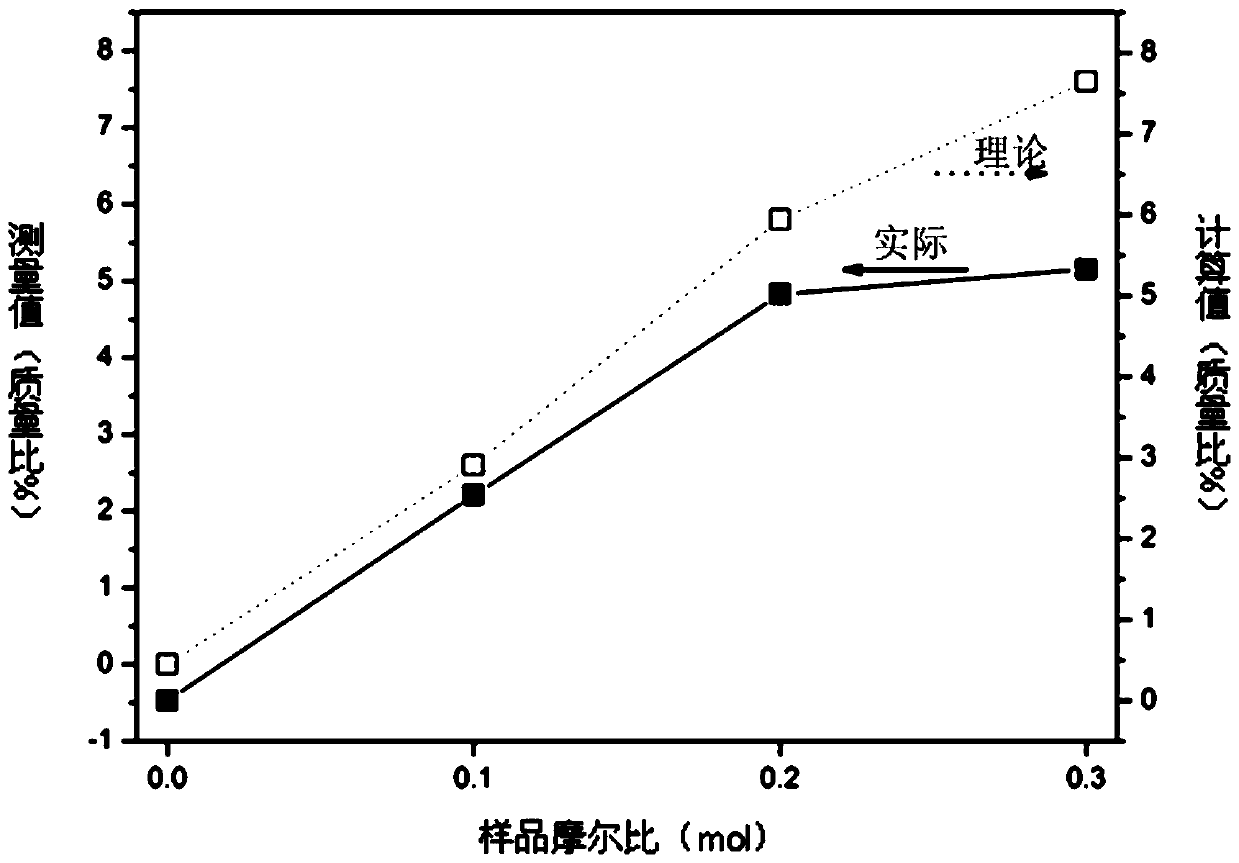

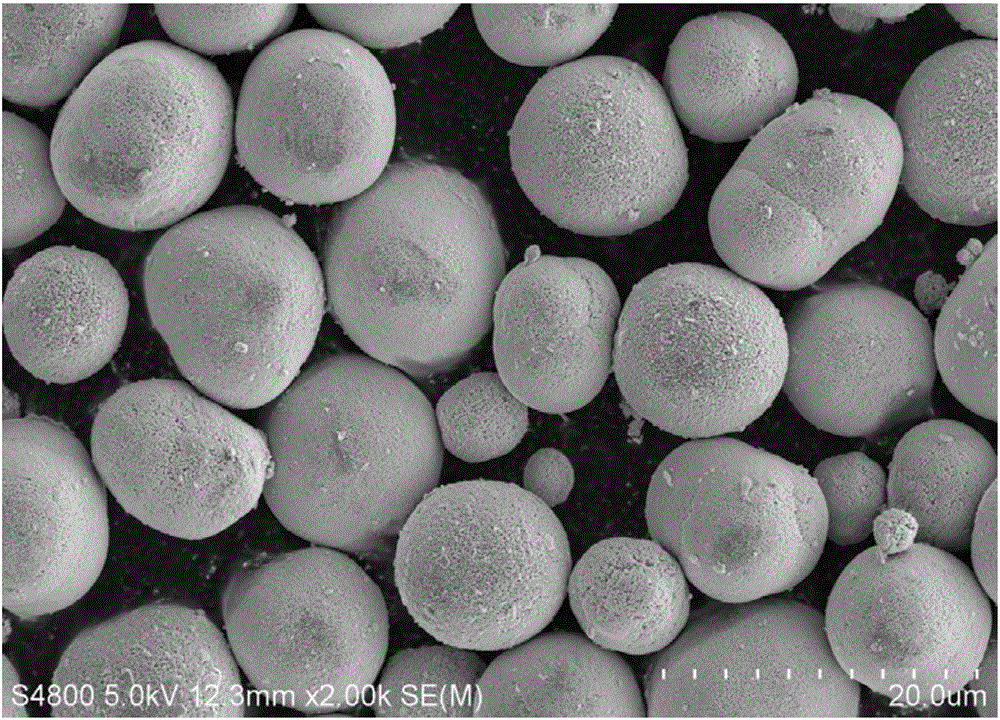

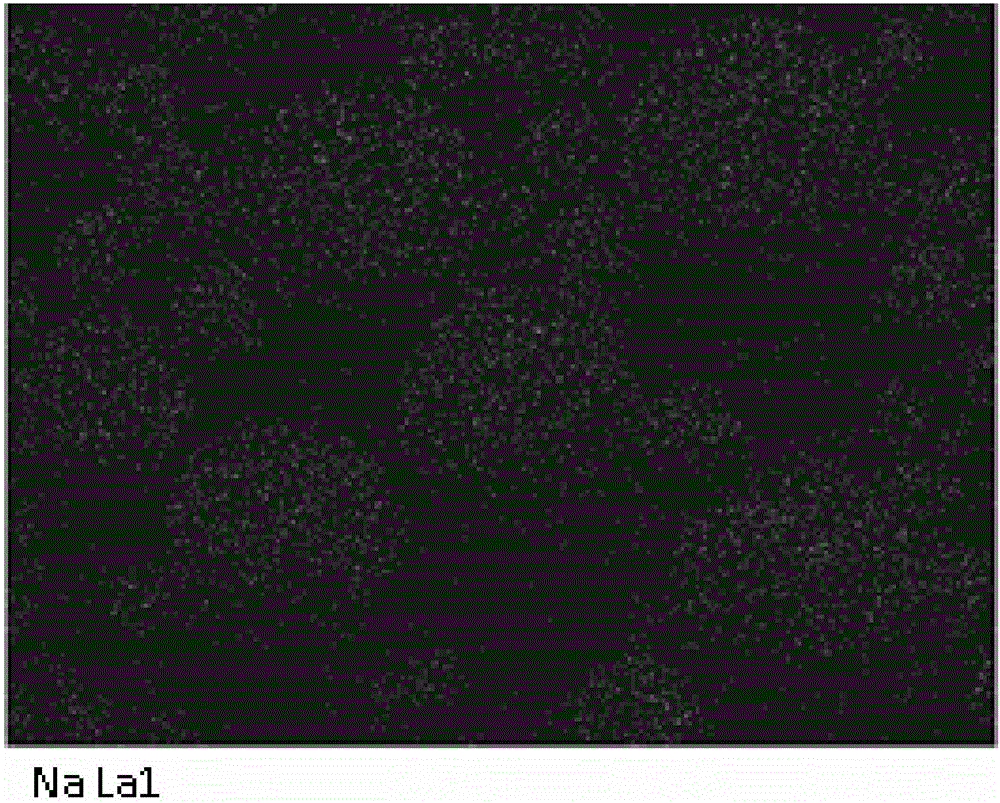

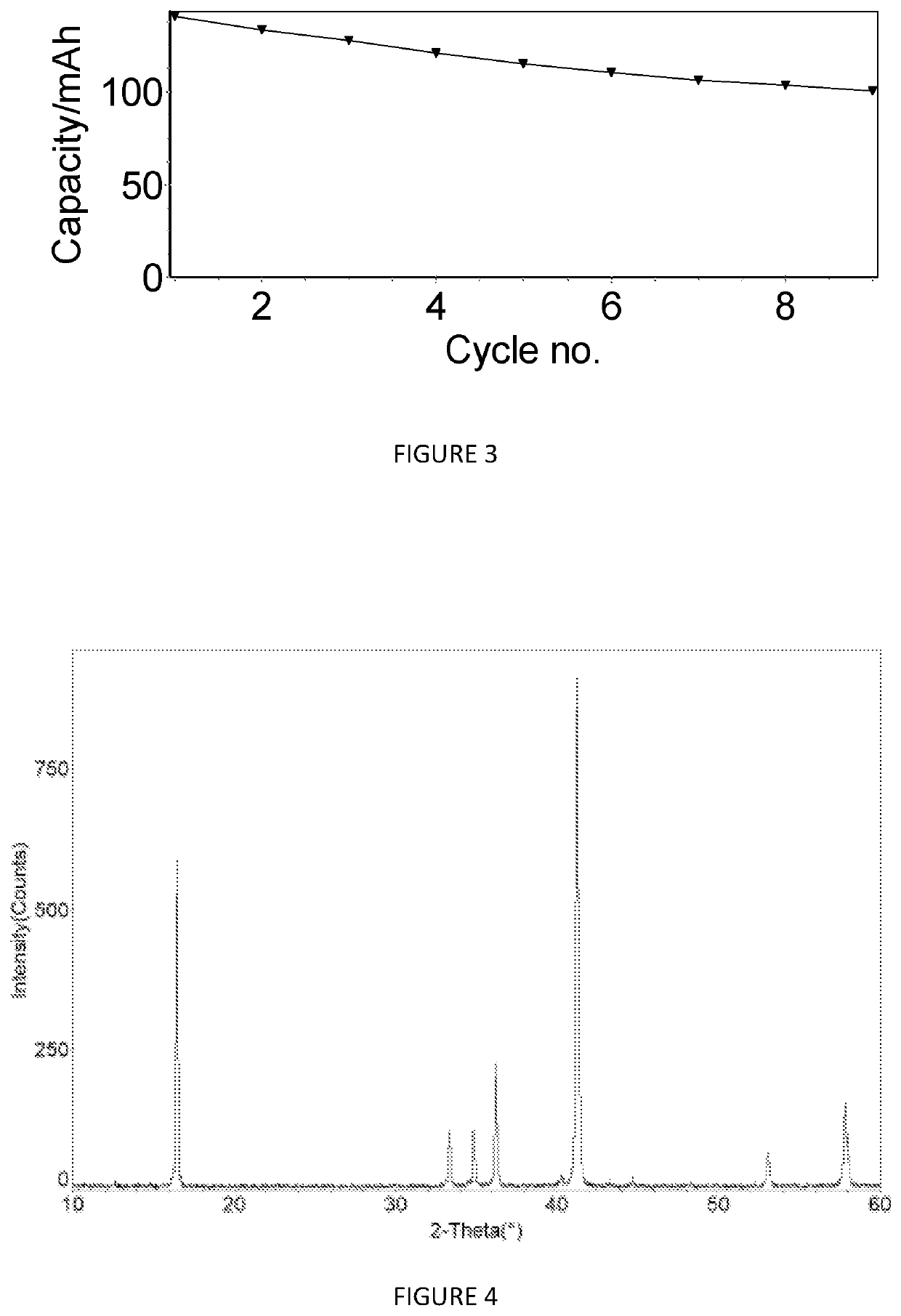

Sodium-doped lithium-rich manganese-based solid solution anode material and preparation method thereof

ActiveCN107180959AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsLithiumManganese

The invention discloses a sodium-doped lithium-rich manganese-based solid solution anode material and a preparation method thereof. In the sodium-doped lithium-rich manganese-based solid solution anode material, a mass content of the doped sodium element is 0.1% to 1%; furthermore, the sodium element is evenly distributed in particles of the lithium-rich manganese-based solid solution anode material; a chemical general formula of the lithium-rich manganese-based solid solution anode material is xLi2MnO3.(1-x)LiNiaCobMncO2, wherein the x is smaller than or equal to 0.7 and larger than or equal to 0.2, the a plus b plug c is equal to 2, the a is smaller than or equal to 0.7 and larger than or equal to 0.3, and the c is smaller than or equal to 0.5 and larger than or equal to 0.2. According to the sodium-doped lithium-rich manganese-based solid solution anode material disclosed by the invention, even doping of the sodium element is achieved, and capacity and circulation performance of the anode material are effectively improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Sodium doping method and system of CIGS based materials using large scale batch processing

InactiveUS7964434B2Improve efficiencyDoping process is simpleFinal product manufactureSemiconductor/solid-state device manufacturingThermal energyBatch processing

A method of processing a plurality of photovoltaic materials in a batch process includes providing at least one transparent substrate having an overlying first electrode layer and an overlying copper species based absorber precursor layer within an internal region of a furnace. The overlying copper species based absorber precursor layer has an exposed face. The method further includes disposing at least one soda lime glass comprising a soda lime glass face within the internal region of the furnace such that the soda lime glass face is adjacent by a spacing to the exposed face of the at least one transparent substrate. Furthermore, the method includes subjecting the at least one transparent substrate and the one soda lime glass to thermal energy to transfer one or more sodium bearing species from the soda lime glass face across the spacing into the copper species based absorber precursor layer via the exposed face.

Owner:CM MFG

A kind of sodium-doped lithium-rich manganese-based positive electrode material for lithium ion battery and preparation method thereof

ActiveCN104201337BImprove cycle stabilityLow application costCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a sodium doped lithium-rich manganese based cathode material for a lithium ion battery. The material is a sodium salt doped lithium-rich manganese based solid solution cathode material of which the general formula is xLi[Li1 / 3Mn2 / 3]O2.(1-x)LiNi0.2Co0.2Mn0.6O2, wherein x is equal to or greater than 0.4 and is equal to or less than 0.7, the doped quantity of sodium elements is 1-10% of the mol content of lithium elements, and the sodium salt is one selected from Na2CO3, Na2C2O4 and NaNO3. The mol content of ternary phase manganese of the sodium doped lithium-rich manganese based cathode material for the lithium ion battery is greater than 50%, and the manganese with high reserves and low price is used for replacing cobalt and nickel, so that the application cost can be reduced. Compared with the prior art, the sodium doping provided by the invention can improve the discharging specific capacity and the circulating stability of the rich lithium manganese based cathode material.

Owner:HEBEI UNIV OF TECH

Sodium-doped molybdenum rotating target material and preparation method thereof

ActiveCN104894517AImprove conversion efficiencyReduce manufacturing costMolten spray coatingVacuum evaporation coatingVolumetric Mass DensityOxygen

The invention provides a sodium-doped molybdenum rotating target material, which is composed of molybdenum atoms, sodium atoms and oxygen atoms, wherein the oxygen atomicity accounts for 85-99% of total atomicity, others are sodium atoms and oxygen atoms, and the quantity ratio of the sodium atoms and oxygen atoms is 1: 2. The invention also provides a preparation method of the sodium-doped molybdenum rotating target material. According to the sodium-doped molybdenum rotating target material, a sodium element is doped in a molybdenum back electrode, transition efficiency of a CIGS film battery is greatly increased, production cost is reduced, and large scale industrialization of the CIGS film battery can be carried out. The preparation method takes molybdenum trioxide, sodium hydroxide and molybdenum metal as raw materials, and processes of reaction, ball milling, sieving, plasma spraying under vacuum or protective atmosphere are carried out to prepare the sodium-doped molybdenum rotating target material. The method has the advantages of simple process and low cost, and is adapted to industrial production, the relative density of the prepared target material can reach more than 95%, oxygen density is less than 250ppm, and length can reach 4000 millimeters.

Owner:无锡舒玛天科新能源技术有限公司

O3/p2 mixed phase sodium-containing doped layered oxide materials

PendingUS20210155501A1High specific capacityExcellent rate performanceSecondary cellsPositive electrodesPhysical chemistryMixed phase

The invention relates to O3 / P2 mixed-phase sodium-containing doped layered oxide materials which comprise a mixture of a first phase with an O3-type structure and a second phase with a P2-type structure; wherein the O3:P2 mixed-phase sodium-containing doped layered oxide material has the general formula: NaaAbM1c M2 M3eM4f M5 O2±δ. The invention also provides a process for making such O3 / P2 mixed-phase sodium-containing doped layered oxide materials, and use applications therefor.

Owner:FARADION

Preparation method of lithium-sodium-doped synergic carbon coated modified lithium barium titanate anode material

ActiveCN106848266AImprove ionic conductivityUniform particle sizeCell electrodesSecondary cellsSodium acetateBarium titanate

The invention relates to a lithium-sodium-doped synergic carbon coated modified lithium barium titanate anode material which is prepared from the following steps of: ball-milling and mixing barium nitrate, lithium nitrate, sodium acetate, titanium dioxide and carbon black; then sintering the obtained powder in a muffle furnace; firstly, pre-sintering the powder at a constant temperature of 650 DEG G for 5 hours to decompose a salt; then sintering the powder at 950 DEG C for 10 hours; naturally cooling the powder to room temperature to obtain the lithium-sodium-doped lithium barium titanate; then putting the obtained lithium-sodium-doped lithium barium titanate in a porcelain boat and placing the porcelain boat in a tubular atmospheric furnace; then placing another porcelain where melamine in the tubular atmospheric furnace too and placing the porcelain in the upstream of an air flow; by taking argon as protective gas, treating the porcelain for 2 hours at 650 DEG C; naturally cooling the same to room temperature; taking out a product and grinding the product into powder; and obtaining the product which is the lithium-sodium-doped synergic carbon coated modified lithium barium titanate anode material.

Owner:NINGBO UNIV

Sodium-doped CIGS (copper indium gallium selenide) solar cell device and production method thereof

InactiveCN104241421AGood adhesionPromote growthFinal product manufacturePhotovoltaic energy generationIndiumCopper indium gallium selenide

A sodium-doped CIGS (copper indium gallium selenide) solar cell device based on a polyimide film and soda glass combined substrate is characterized in that the substrate is composed of soda glass and a polyimide film grown on the surface of the substrate; a CIGS solar cell is produced on the surface of the substrate. The sodium-doped CIGS solar cell device has the advantages that adhesion of the CIGS film on the substrate is excellent, crystal quality is high, grains are thick and large, and defects are few; after the complete CIGS solar cell is produced, the CIGS solar cell is separated from the soda glass to form a flexible CIGS solar cell with the polyimide film as a substrate, and a flexible cell can be produced with the rigid substrate; a production method is simple, easy to implement and convenient to popularize and apply on a large scale and has extremely important application prospect in space and special places.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

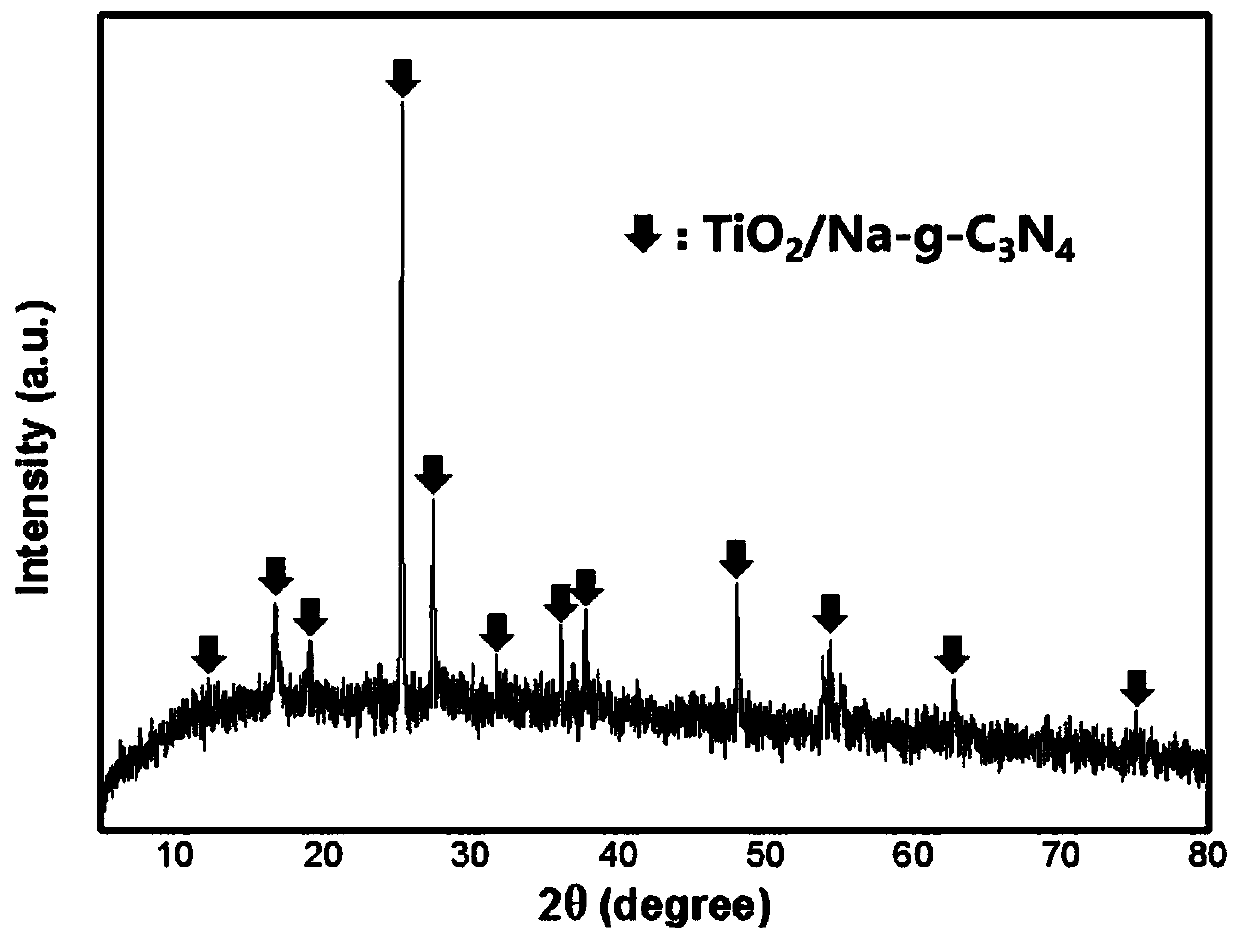

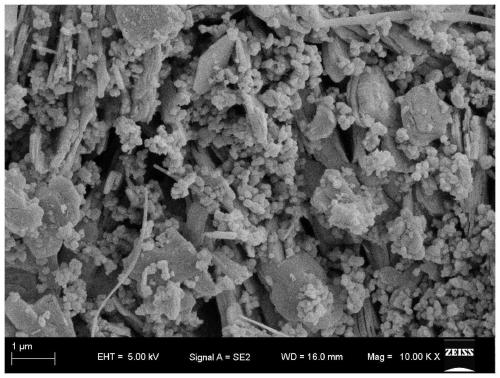

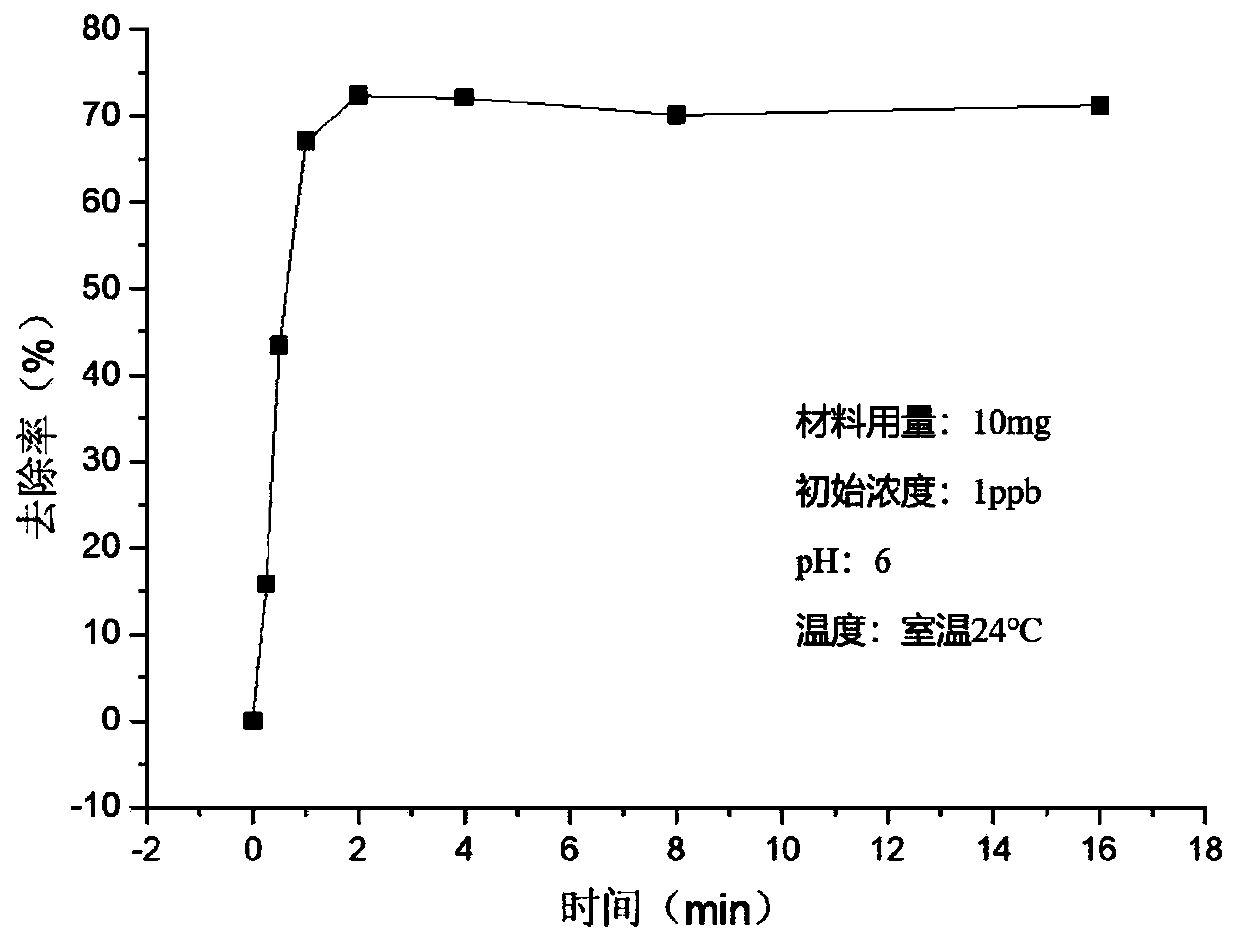

Graphite phase carbon nitride composite and preparation method and application thereof

ActiveCN110368893AGood removal effectFast removal rateOther chemical processesNuclear energy generationCarbon compositesCarbon nitride

The invention discloses a graphite phase carbon nitride composite, and a preparation method and application thereof. The graphite phase carbon nitride composite takes titanium dioxide as a matrix, andthe surface of the matrix is coated with a sodium doped graphite phase carbon nitride of a heptazine ring structure. During preparation, the titanium dioxide, a precursor and a sodium ion compound are subjected to a thermal polymerization reaction, wherein the precursor can form the graphite phase carbon nitride of the heptazine ring structure. The synthesized graphite phase carbon nitride composite has an excellent removing effect on heavy metal ions, also has a good removing effect on the content of cobalt ions in a water phase under the situation of the extremely low concentration and is simple in synthesis process, good in stability and low in cost.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com