Novel carbon dioxide adsorbent and preparation method thereof

A carbon dioxide and adsorbent technology, applied in the field of materials, to achieve the effect of perfect shape, low calcination temperature and strong chemical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

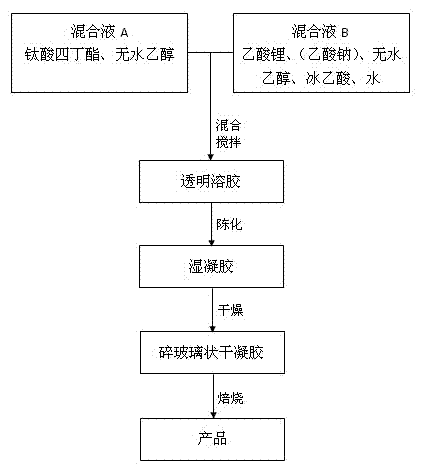

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: The described sol-gel method prepares lithium metatitanate, chemical formula Li 2 TiO 3 Ratio of each raw material in the process:

[0041] The molar ratio of lithium acetate to tetrabutyl titanate=2:1;

[0042] The volume ratio of absolute ethanol to tetrabutyl titanate=4:1;

[0043] The molar ratio of water to tetrabutyl titanate=20:1;

[0044] The molar ratio of acetic acid to tetrabutyl titanate = 4:1.

Embodiment 2

[0045] Embodiment 2: The described sol-gel method prepares lithium metatitanate, chemical formula Li 2 TiO 3 Ratio of each raw material in the process:

[0046] The molar ratio of lithium acetate to tetrabutyl titanate=2:1;

[0047] The volume ratio of absolute ethanol to tetrabutyl titanate=6:1;

[0048] The molar ratio of water to tetrabutyl titanate=30:1;

[0049] The molar ratio of acetic acid to tetrabutyl titanate = 7:1.

Embodiment 3

[0050] Embodiment 3: The described sol-gel method prepares lithium metatitanate, chemical formula Li 2 TiO 3 Ratio of each raw material in the process:

[0051] The molar ratio of lithium acetate to tetrabutyl titanate=2:1;

[0052] The volume ratio of absolute ethanol to tetrabutyl titanate=5:1;

[0053] The molar ratio of water to tetrabutyl titanate=25:1;

[0054] The molar ratio of acetic acid to tetrabutyl titanate = 5.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com