Method for manufacturing sodium-doped absorbing layer on reel-to-reel flexible polyimide (PI) substrate

A flexible substrate and absorber layer technology, which is applied in the field of copper indium gallium selenium thin film solar cells, can solve the problems of decreased adhesion of the absorber layer, affecting life, and lower temperature of flexible PI substrates, and achieves the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

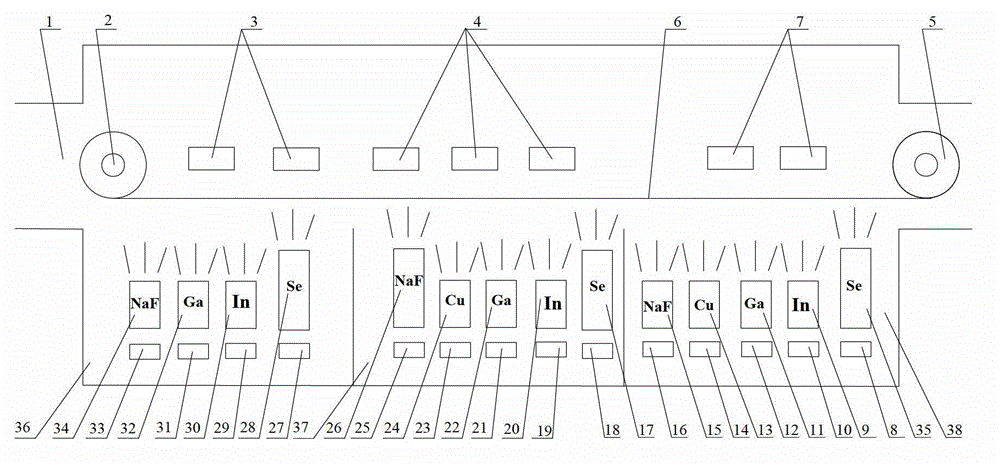

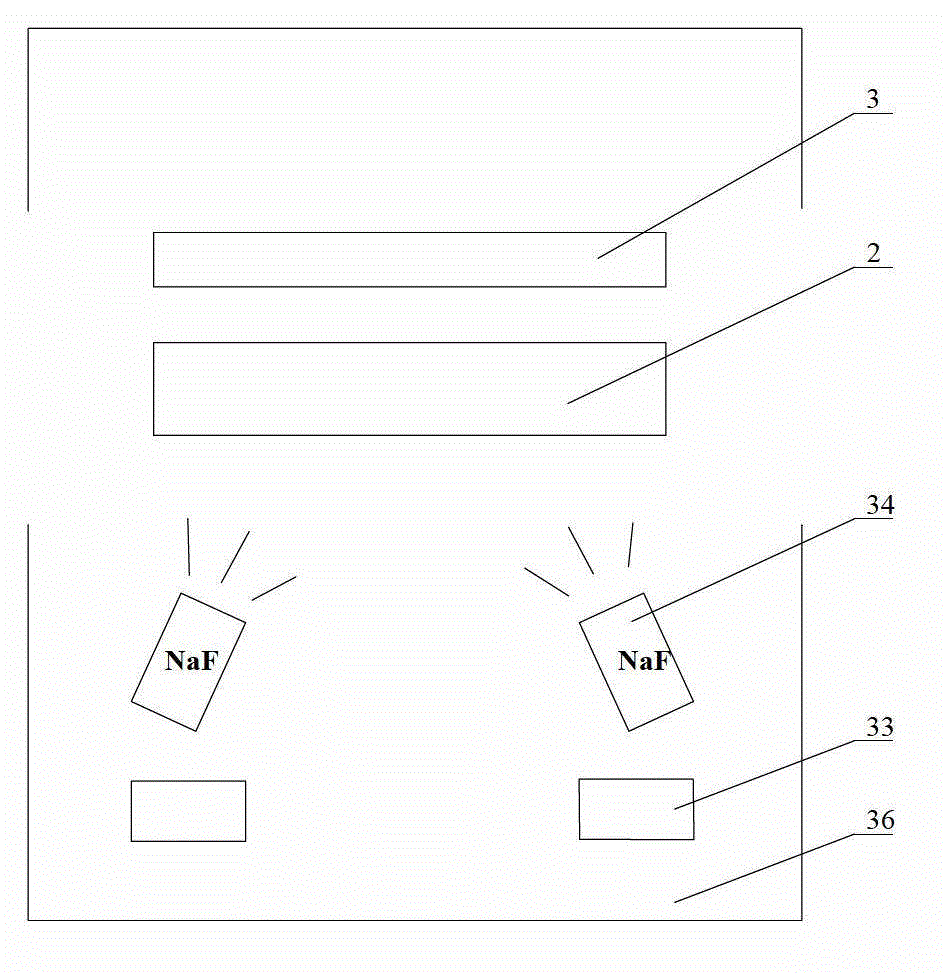

[0024] The preparation steps of the present invention, such as Figure 1-2 Shown:

[0025] Step 1: Preparation before work

[0026] The outer end of the whole roll of PI flexible substrate on the starting roller 2 in the vacuum chamber for preparing the absorbing layer is rolled onto the terminal roller 5 to form a roll-to-roll PI flexible substrate 6. After winding, the two The PI flexible substrate between the rollers forms a horizontal plane, and the side on which the back electrode Mo is deposited is facing down. In the film deposition chamber, the bottom of the back electrode Mo is the first process chamber (hereinafter referred to as the first chamber) 36 and the second chamber from left to right. The second process chamber (hereinaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com