Sodium sputtering doping method for large scale cigs based thin film photovoltaic material

A thin-film photovoltaic and sodium-doped technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems that cannot be applied in a wide range of time, difficult to integrate thin films, and poor reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

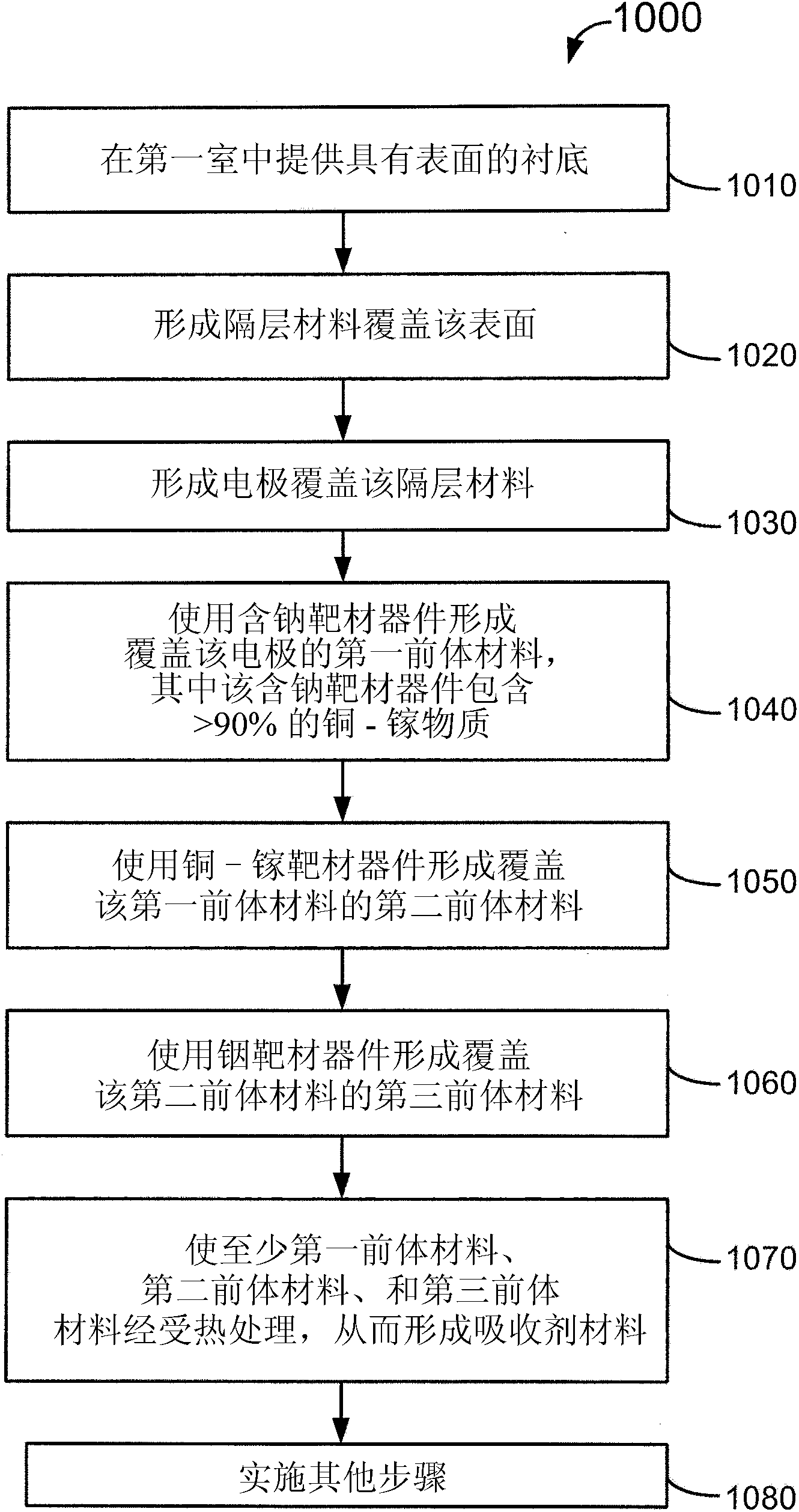

[0014] figure 1 is a flowchart illustrating a method of fabricating a thin film photovoltaic material according to an embodiment of the present invention. The method 1000 includes the following processes:

[0015] 1. Process 1010 for providing a transparent substrate having a surface;

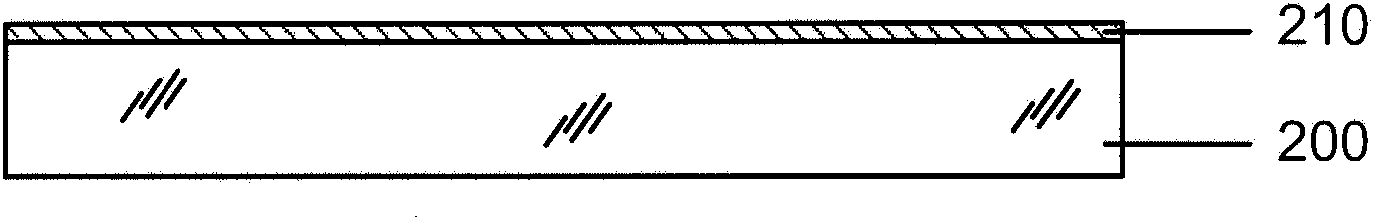

[0016] 2. Process 1020 for forming a barrier material on the surface;

[0017] 3. Process 1030 for forming electrodes;

[0018] 4. Process 1040 for forming a first precursor material overlying the electrode using a sodium-containing target device, wherein the sodium-containing target device comprises >90% copper-gallium species;

[0019] 5. Process 1050 for forming a second precursor material overlying the first precursor material using a copper-gallium target device;

[0020] 6. Process 1060 for forming a third precursor material overlying the second precursor material using an indium target device;

[0021] 7. Process 1070 for subjecting at least a first precursor material, a second prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com