Preparation method of sodium-doped molybdenum plane sputtering target material

A sputtering target material, sodium doping technology, applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of low conversion efficiency and high cost of copper indium gallium selenide thin film, and achieve cost Low cost, high relative density, and the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

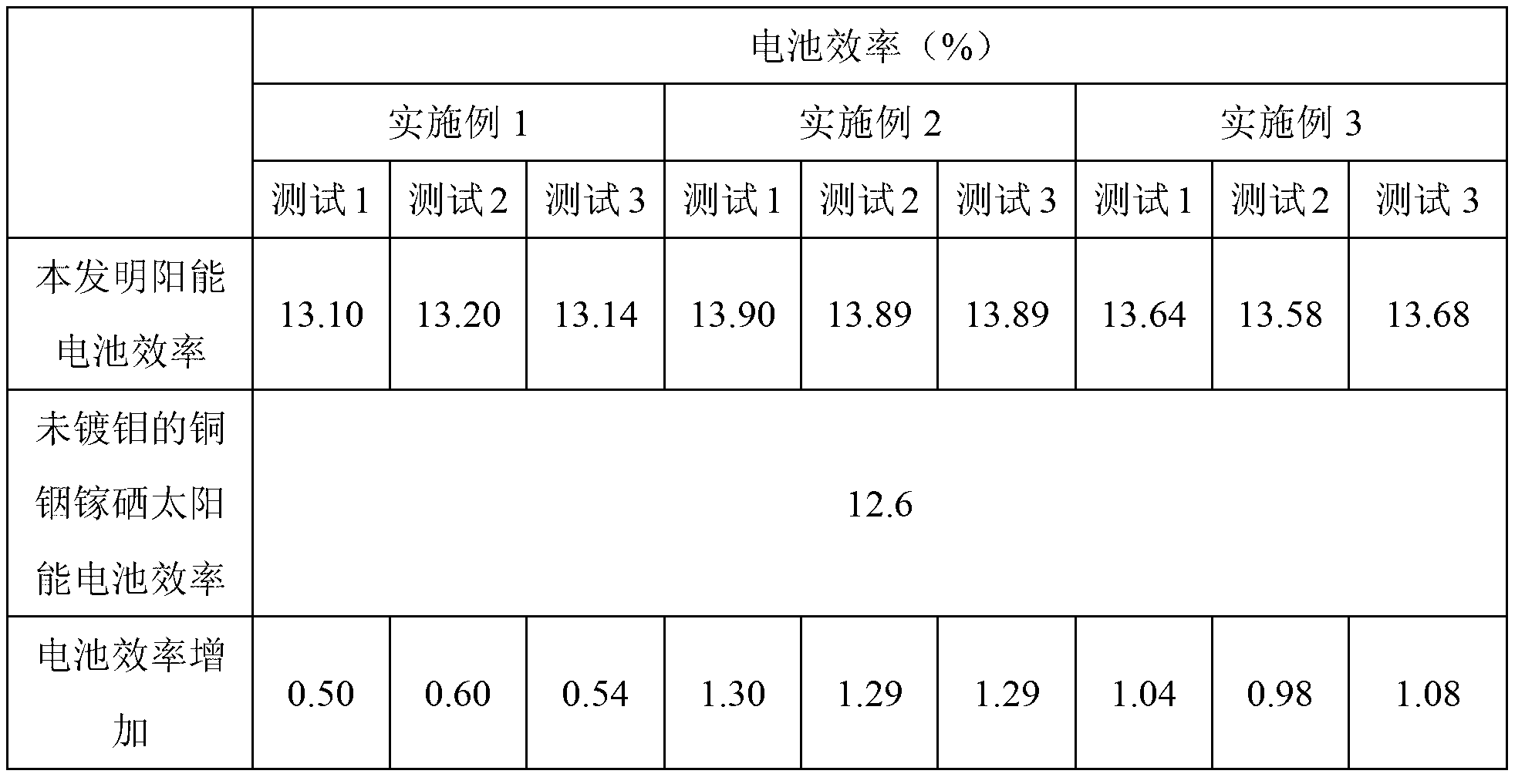

Embodiment 1

[0023] Sodium-doped molybdenum planar sputtering target is composed of molybdenum atoms, sodium atoms and oxygen atoms, wherein the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 85:5:10.

[0024] Its preparation method comprises the following steps:

[0025] (1) Molybdenum trioxide with a molar ratio of 1:1 and a purity of more than 99.99% and sodium hydroxide are reacted in water at 50°C to form an aqueous solution of sodium molybdate, and heated to 120°C to evaporate the aqueous solution of sodium molybdate to dryness to obtain Sodium molybdate;

[0026] (2) Precisely weigh anhydrous sodium molybdate and molybdenum powder so that the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 85:5:10, mix them well, place them in a ball mill jar, and add balls, in which anhydrous molybdenum The ratio of the total mass of sodium bicarbonate and molybdenum powder to the total mass of balls added to the ball mill is 1:10, ball milled for 180min under the protecti...

Embodiment 2

[0030] Sodium-doped molybdenum planar sputtering target is composed of molybdenum atoms, sodium atoms and oxygen atoms, wherein the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 91:3:6.

[0031] Its preparation method comprises the following steps:

[0032] (1) Molybdenum trioxide with a molar ratio of 1:2 and a purity of more than 99.99% is reacted with sodium hydroxide in water at 70°C to form an aqueous solution of sodium molybdate, which is heated to 100°C to evaporate the aqueous solution of sodium molybdate to dryness. Sodium molybdate;

[0033] (2) Precisely weigh anhydrous sodium molybdate and molybdenum powder so that the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 91:3:6, mix them evenly, place them in a ball mill jar, and add balls, in which anhydrous molybdenum The ratio of the total mass of sodium bicarbonate and molybdenum powder to the total mass of balls added to the ball mill is 1:100, ball milled for 30 minutes under the protect...

Embodiment 3

[0037] Sodium-doped molybdenum planar sputtering target is composed of molybdenum atoms, sodium atoms and oxygen atoms, wherein the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 99:1 / 3:2 / 3.

[0038] Its preparation method comprises the following steps:

[0039] (1) Molybdenum trioxide with a molar ratio of 1:3 and a purity of more than 99.99% is reacted with sodium hydroxide in water at 60°C to form an aqueous solution of sodium molybdate, which is heated to 110°C to evaporate the aqueous solution of sodium molybdate to dryness. Sodium molybdate;

[0040] (2) Precisely weigh anhydrous sodium molybdate and molybdenum powder so that the ratio of molybdenum atoms, sodium atoms and oxygen atoms is 99:1 / 3:2 / 3, mix them well, put them in a ball mill jar, and add balls, The ratio of the total mass of anhydrous sodium molybdate and molybdenum powder to the total mass of balls added to the ball mill is 1:50, ball milled for 100min under the protection of argon, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com