Preparation method of lithium-sodium-doped synergic carbon coated modified lithium barium titanate anode material

A nitrogen-doped carbon and sodium-doped technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low electronic and ionic conductivity, inability to obtain high-power and long-life lithium-ion battery anode materials, etc. , to achieve the effect of uniform particle size, superior electrochemical performance, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

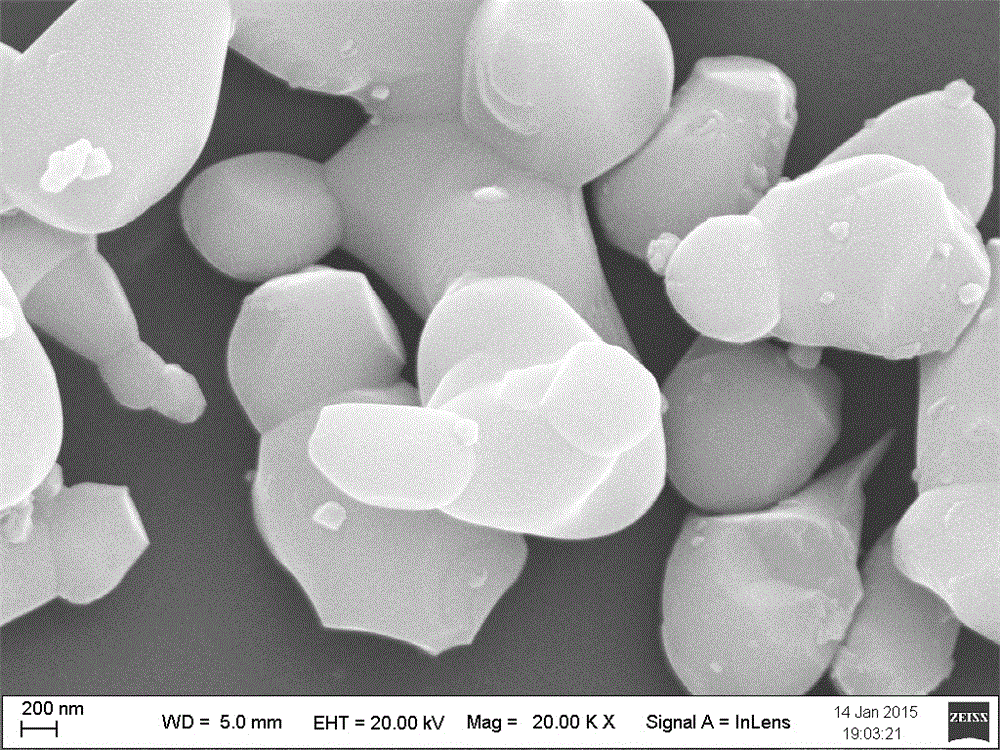

Image

Examples

Embodiment 1

[0011] Example 1: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.01 mole of sodium acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of carbon black, mix them by ball milling at 400 rpm for 19 hours, and place them in an oven at 150°C After drying, grind it finely in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 5 hours for pre-calcination to decompose the salts, and then It takes 2 hours to raise the temperature to 950°C, and keep it at this temperature for 10 hours, and then naturally cool to room temperature to obtain lithium-site sodium-doped barium lithium titanate. Next, put the obtained lithium-site sodium-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing melamine into a tube atmosphere furnace and place it in an...

Embodiment 2

[0012] Example 2: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.03 mole of sodium acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of carbon black, mix them by ball milling at 400 rpm for 19 hours, and place them in an oven at 150°C After drying, grind it finely in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 5 hours for pre-calcination to decompose the salts, and then It takes 2 hours to raise the temperature to 950°C, and keep it at this temperature for 10 hours, and then naturally cool to room temperature to obtain lithium-site sodium-doped barium lithium titanate. Next, put the obtained lithium-site sodium-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing melamine into a tube atmosphere furnace and place it in an...

Embodiment 3

[0013]Example 3: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.05 mole of sodium acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of carbon black, mix them by ball milling at 400 rpm for 19 hours, and place them in an oven at 150 ° C. After drying, grind it finely in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 5 hours for pre-calcination to decompose the salts, and then It takes 2 hours to raise the temperature to 950°C, and keep it at this temperature for 10 hours, and then naturally cool to room temperature to obtain lithium-site sodium-doped barium lithium titanate. Next, put the obtained lithium-site sodium-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing melamine into a tube atmosphere furnace and place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com