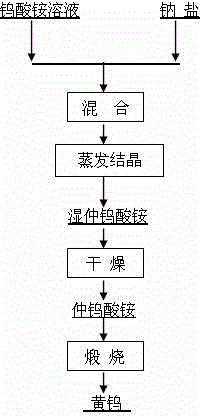

Preparation method of uniform sodium-doped ammonium paratungstate and/or yellow tungsten oxide

A technology of sodium ammonium paratungstate and ammonium paratungstate, which is applied in the field of tungsten smelting, can solve the problems of uneven particle growth, influence, and uneven distribution of sodium, and achieve uniform distribution of sodium elements, simple process control, and less doping procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ammonium tungstate feed solution produced by alkali decomposition of tungsten concentrate through ion exchange, molybdenum removal and other processes, WO 3 The concentration is 264.80 g / L, Na + The concentration is 20 ppm. Take 189.0 mL of the feed solution in a polytetrafluoroethylene beaker, press Na / WO 3 Add 0.3672 g NaHCO to 0.20% by mass 3 , Evaporated and crystallized to obtain sodium-containing APT powder. Other process conditions are: stirring speed 50 r / min, crystallization temperature 100°C, crystallization endpoint pH=6.7, cooling to 20°C.

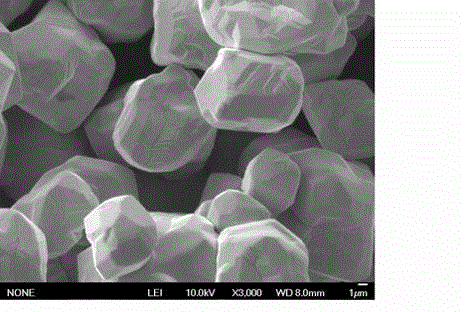

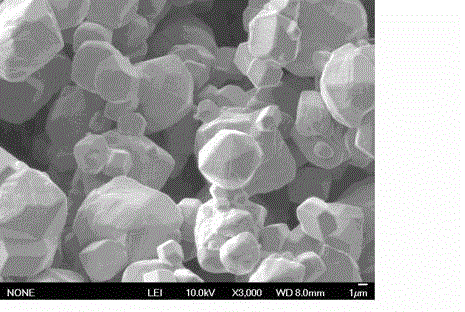

[0028] The results of elemental analysis by electron microscope (SEM) and energy dispersive spectrometer (EDS) in this example are shown in figure 2 .

Embodiment 2

[0030] Ammonium tungstate feed solution produced by alkali decomposition of tungsten concentrate through ion exchange, molybdenum removal and other processes, WO 3 The concentration is 208.33 g / L, Na + The concentration is 14 ppm. Take 240.0 mL of the feed solution in a polytetrafluoroethylene beaker, press Na / WO 3 Add 0.2183 g NaOH to 0.25% by mass, evaporate and crystallize to obtain sodium-containing APT powder. Other processing conditions are with example 1.

[0031] Result is comparable with example 1, can refer to example 1.

Embodiment 3

[0033] Ammonium tungstate feed solution produced by alkali decomposition of tungsten concentrate through ion exchange, molybdenum removal and other processes, WO 3 Concentration 285.57g / L, Na + The concentration is 32 ppm. Take 500.0 mL of the feed solution in a polytetrafluoroethylene beaker, press Na / WO 3 Add 1.5426 g Na at 0.15% by mass 2 WO 4 , Evaporated and crystallized to obtain sodium-containing APT powder. Other process conditions are: stirring speed 150 r / min, crystallization temperature 90°C, crystallization endpoint pH=7.0, cooling to 35°C.

[0034] Result is comparable with example 1, can refer to example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com