Graphite phase carbon nitride composite and preparation method and application thereof

A technology of graphite phase carbon nitride and composite materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of weak removal effect of heavy metal ions and achieve good removal effect , fast removal rate and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First weigh 0.6g melamine solid powder, 2.4g titanium dioxide solid powder and 1.8g sodium bicarbonate solid powder, place them in a 200mL beaker at room temperature, add an appropriate amount of absolute ethanol, the amount of absolute ethanol is controlled at just enough to mix it Stir continuously for 30 minutes during the ultrasonic process to make it evenly mixed, then put the mixture in a blast drying oven, dry at 60°C for 3 hours, take it out, grind it into a fine powder in an agate crucible, and cover it evenly on the Put it in a 103mm×40mm×21mm alumina crucible, place it in a vacuum tube type high-temperature sintering furnace tube, raise the temperature to 550℃ at a rate of 3℃ / min, keep it at this temperature for 3 hours, cool it down to room temperature, take it out and grind it into powder shape, the desired product is obtained.

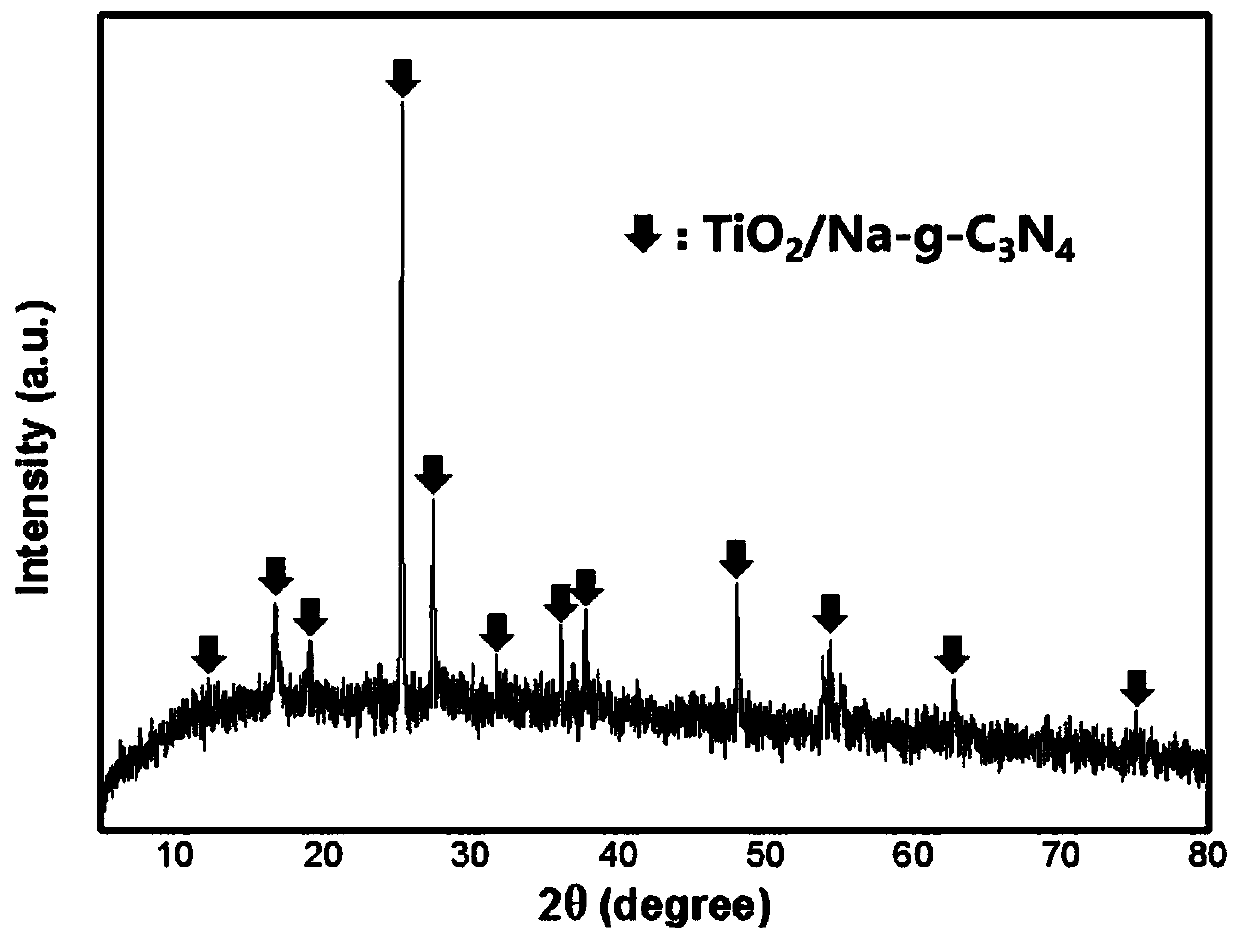

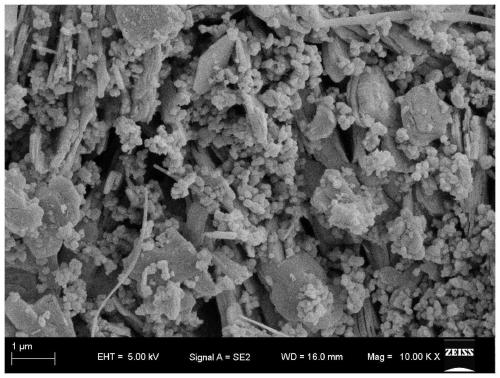

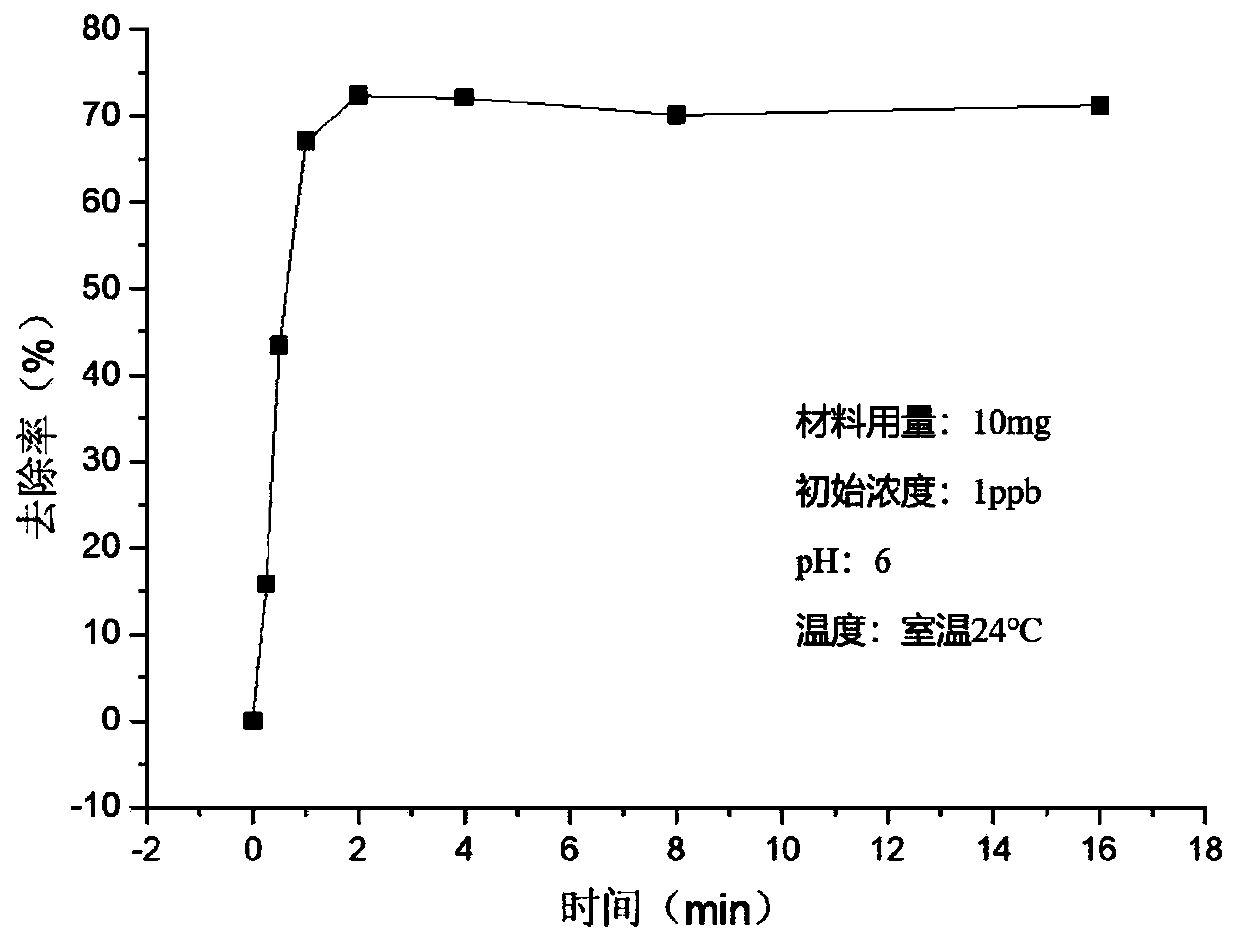

[0037] figure 1 It is the XRD pattern of the graphite phase carbon nitride composite material obtained in the present embodiment...

Embodiment 2

[0039] First take by weighing 1.2g melamine solid powder, 4.8g titanium dioxide solid powder and 3.6g sodium bicarbonate solid powder, place them in a 200mL beaker at room temperature, add an appropriate amount of absolute ethanol, and the amount of absolute ethanol is controlled at just enough to mix it Stir continuously for 30 minutes during the ultrasonic process to make it evenly mixed, then put the mixture in a blast drying oven, dry at 60°C for 3 hours, take it out, grind it into a fine powder in an agate crucible, and cover it evenly on the Put it in a 103mm×40mm×21mm alumina crucible, place it in a vacuum tube type high-temperature sintering furnace tube, raise the temperature to 550℃ at a rate of 3℃ / min, keep it at this temperature for 3 hours, cool it down to room temperature, take it out and grind it into powder shape, the desired product is obtained.

Embodiment 3

[0041] First take by weighing 2.4g of melamine solid powder, 9.6g of titanium dioxide solid powder and 7.2g of sodium bicarbonate solid powder, place them in a 200mL beaker at room temperature, add an appropriate amount of absolute ethanol, the amount of absolute ethanol is controlled at just enough to mix it Stir continuously for 30 minutes during the ultrasonic process to make it evenly mixed, then put the mixture in a blast drying oven, dry at 60°C for 3 hours, take it out, grind it into a fine powder in an agate crucible, and cover it evenly on the Put it in a 103mm×40mm×21mm alumina crucible, place it in a vacuum tube type high-temperature sintering furnace tube, raise the temperature to 550℃ at a rate of 3℃ / min, keep it at this temperature for 3 hours, cool it down to room temperature, take it out and grind it into powder shape, the desired product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com