Method for preparing sodium-doped blue tungsten oxide nano-powder and dispersion liquid thereof

A technology of blue tungsten oxide and nanopowder, which is applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., which can solve the problems of poor performance batch stability, long reaction cycle, and efficiency Low and other problems, to achieve the effect of improving uniformity, increasing uniformity and fineness, and improving particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

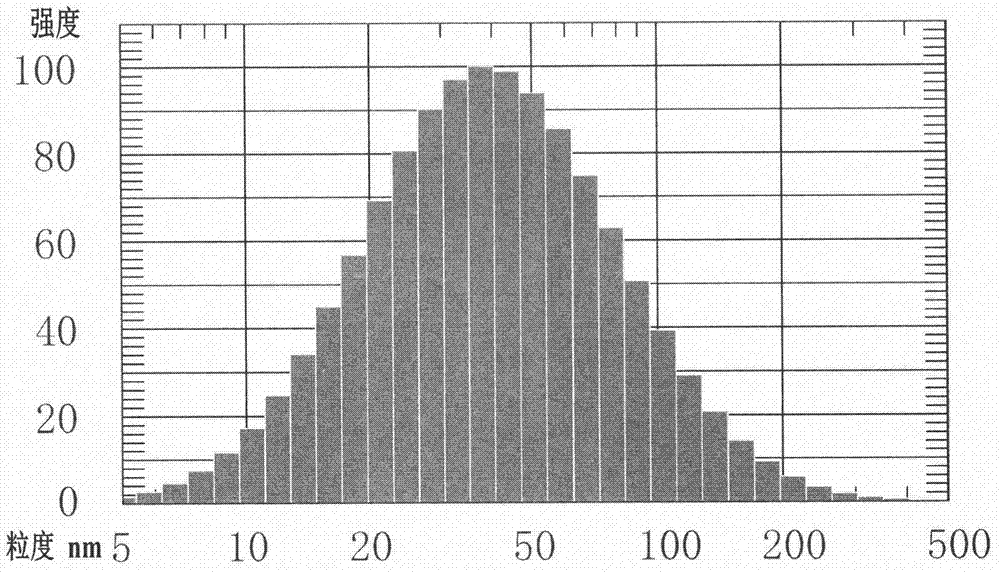

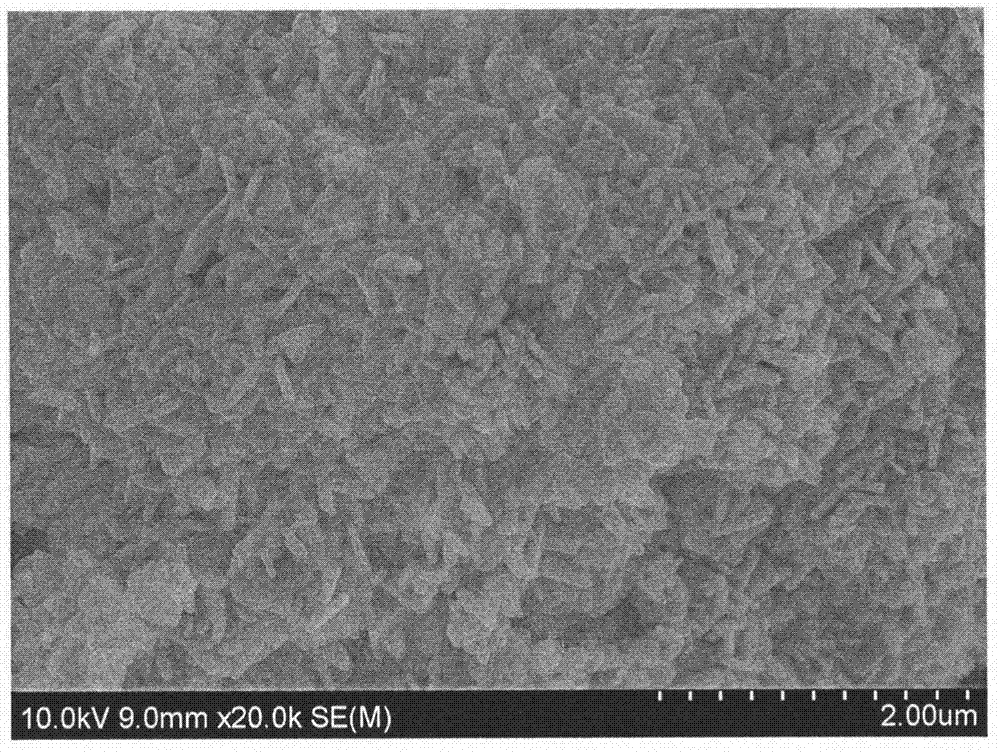

[0023] Example 1: According to the volume ratio of 1:0.01, 300ml of ethanol and 3ml of alcoholysis inhibitor nitric acid were premixed to form a mixed solution; the compound of sodium and tungsten was dosed according to the molar ratio of Na:W=0.01:1, and 5g was weighed Add sodium nitrate to the above mixed solution, stir evenly to form a suspension of sodium nitrate, then weigh 233.29g of tungsten chloride, add it to the suspension of sodium nitrate, stir at room temperature with a magnetic heating stirrer, and then put it into the planetary Grinding in a ball mill for 1 hour, after the alcoholysis of the tungsten compound is completed, take it out and dry it to obtain a solid-phase precursor; roast the solid-phase precursor in a hydrogen-argon reducing atmosphere at 400°C for 10 hours, and finally obtain a sodium-doped blue Tungsten oxide nanopowder Na 0.01 WO 3-δ ; The mixed slurry of 100g sodium-doped blue tungsten oxide, 5g organic polyphosphate dispersant and 895g deion...

Embodiment 2

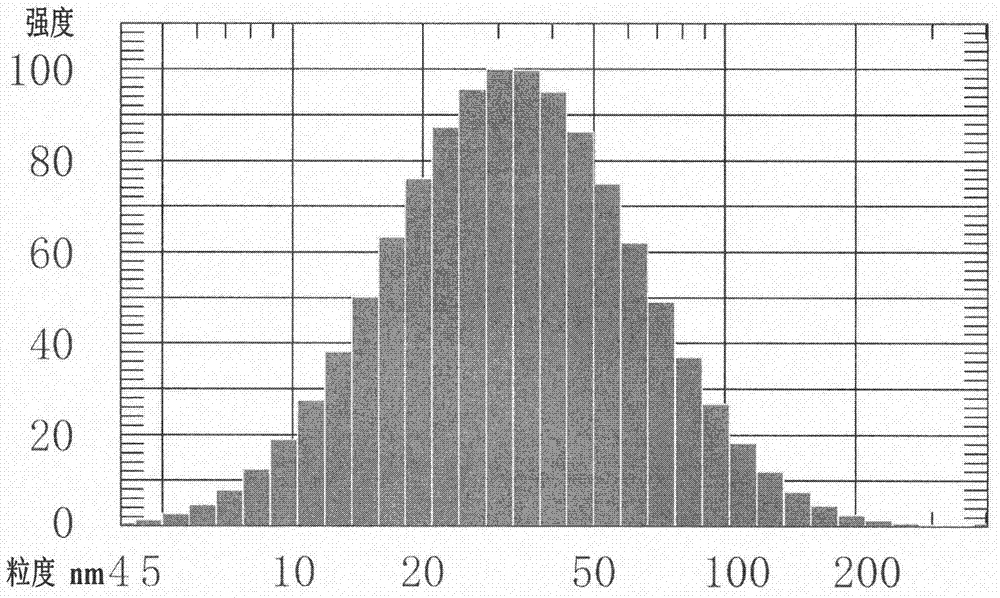

[0024] Example 2: According to the volume ratio of 1:0.05, 300ml of ethanol and 15ml of alcoholysis inhibitor hydrochloric acid were premixed to form a mixed solution; the compound of sodium and tungsten was dosed according to the molar ratio of Na:W=0.5:1, and 2g was weighed Add sodium nitrate to the above mixed solution, stir evenly to form a suspension of sodium nitrate, then weigh 16.08g of tungsten oxychloride, add it to the suspension of sodium nitrate, stir at room temperature with a magnetic heating stirrer, and then put Grinding in a planetary ball mill for 5 hours, after the alcoholysis of the tungsten compound was completed, it was taken out and dried to obtain a solid-phase precursor; the solid-phase precursor was roasted in a hydrogen-argon reducing atmosphere at 500°C for 5 hours, and finally a sodium-doped blue Color tungsten oxide nanopowder Na 0.5 WO 3-δ The mixed slurry of 300g sodium-doped blue tungsten oxide, 30g propylene glycol block polyester dispersant...

Embodiment 3

[0025] Example 3: According to the volume ratio of 1:0.1, 300ml of ethanol and 30ml of alcoholysis inhibitor oxalic acid are premixed to form a mixed solution; the compound of sodium and tungsten is dosed according to the molar ratio of Na:W=1:1, and 20g is weighed Add sodium nitrate into the above mixed solution, stir evenly to form a suspension of sodium nitrate, then weigh 67.47g of tungsten dioxide dichloride, add it to the suspension of sodium nitrate, stir at room temperature with a magnetic heating stirrer, and then Put it into a planetary ball mill for grinding for 8 hours. After the alcoholysis of the tungsten compound is completed, take it out and dry it to obtain a solid-phase precursor; roast the solid-phase precursor in a hydrogen-argon reducing atmosphere at 650°C for 2 hours, and finally obtain a sodium-doped Blue tungsten oxide nanopowder NaWO 3-δ ;The mixed slurry of 600g sodium-doped blue tungsten oxide, 100g polyoxypropylene polyoxyethylene copolymer dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com