Preparation method of high-performance aluminum and potassium co-doped sodium vanadium fluorophosphates/carbon composite material

A technology of sodium vanadium fluorophosphate and carbon composite material, which is used in electrical components, electrochemical generators, battery electrodes and other directions to achieve the effects of excellent electrochemical performance, improved electronic conductivity, improved sodium ion conductivity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0018] Implementation Case 1: Weigh 0.01455mol of vanadium pentoxide, 0.03mol of ammonium dihydrogen phosphate, 0.0009mol of aluminum nitrate and 0.0075mol of sucrose, and transfer them all to a ball mill jar, and add about 20% polyethylene glycol by weight of the solid mixture (molecular weight is 200), start the ball mill, mix the mixture evenly, and dry the mixture in an oven at 180°C, transfer the dried mixture to a tube furnace, and under the protection of an argon atmosphere, heat at 2°C / min The heating rate is heated to 700°C, kept at a constant temperature for 8 hours, and cooled to room temperature with the furnace, then V 0.97 Al 0.03 PO 4 / C Composite. The prepared V 0.97 Al 0.03 PO 4 / C Mix all the materials with 0.0291mol sodium fluoride and 0.0009mol potassium fluoride evenly, then transfer the mixture to a tube furnace, and heat it to 700°C at a heating rate of 2°C / min under the protection of an argon atmosphere. 1h, cool to room temperature with the furna...

Embodiment example 2

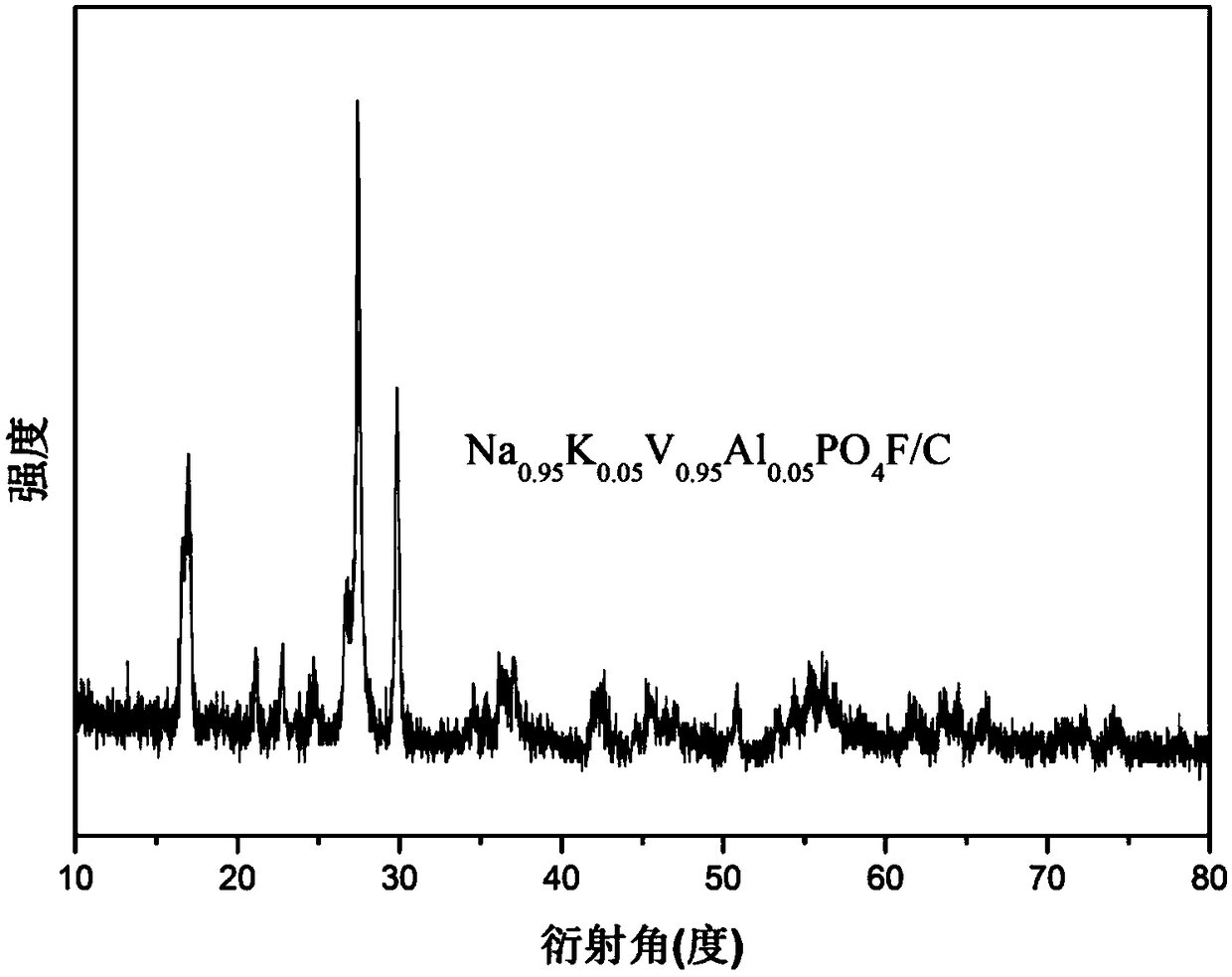

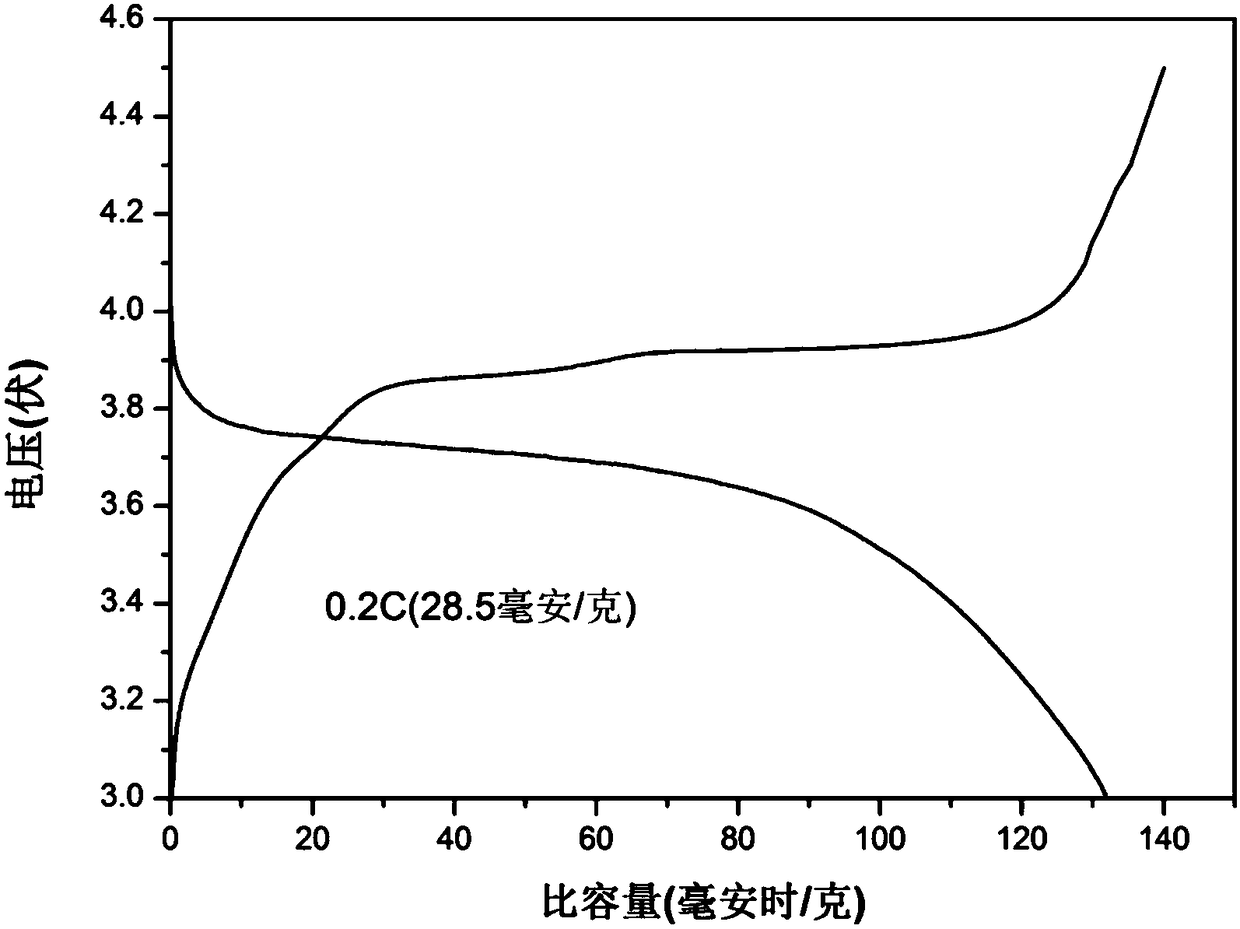

[0020] Implementation case 2: Weigh 0.01425mol vanadium pentoxide, 0.03mol diammonium phosphate, 0.0015mol aluminum nitrate and 0.015mol glucose, and transfer to the ball mill jar, and add about 20% Polyethylene Glycol ( The molecular weight is 400), start the ball mill, mix the mixture evenly, and dry the mixture in an oven at 180°C, transfer the dried mixture to a tube furnace, and under the protection of an argon atmosphere, heat at 5°C / min Heating rate to 750°C, constant temperature for 6 hours, and cooling to room temperature with the furnace, then V 0.95 Al 0.05 PO 4 / C Composite. The prepared V 0.95 Al0.05 PO 4 / C All materials are mixed evenly with 0.0285mol sodium fluoride and 0.0015mol potassium fluoride, then the mixture is transferred to a tube furnace, and heated to 750°C at a heating rate of 5°C / min under the protection of an argon atmosphere. Constant temperature for 1h, then cool down to room temperature with the furnace, then Na 0.95 K 0.05 V 0.95 al ...

Embodiment example 3

[0022] Implementation Case 3: Weigh 0.0135mol vanadium pentoxide, 0.03mol diammonium hydrogen phosphate, 0.003mol aluminum nitrate and 0.015mol fructose, and transfer them all to a ball mill jar, and add about 10% polyethylene glycol by weight of the solid mixture (molecular weight is 600), start the ball mill, mix the mixture evenly, and dry the mixture in an oven at 160°C, transfer the dried mixture to a tube furnace, and under the protection of an argon atmosphere, heat at 5°C / min The heating rate is heated to 800°C, kept at a constant temperature for 4 hours, and cooled to room temperature with the furnace, then V 0.9 al 0.1 PO 4 / C Composite. The prepared V 0.9 al 0.1 PO 4 / C Mix all the materials with 0.0285mol sodium acetate, 0.0015mol potassium acetate, and 0.03mol ammonium fluoride, then transfer the mixture to a tube furnace, and heat it at a heating rate of 5°C / min under the protection of an argon atmosphere to 750°C, keep the temperature constant for 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com