Sodium-doped lithium-rich manganese-based solid solution anode material and preparation method thereof

A lithium-rich manganese-based, cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of rapid capacity decay, poor cycle performance, low capacity, etc., to avoid poor doping consistency, improve Effects on capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

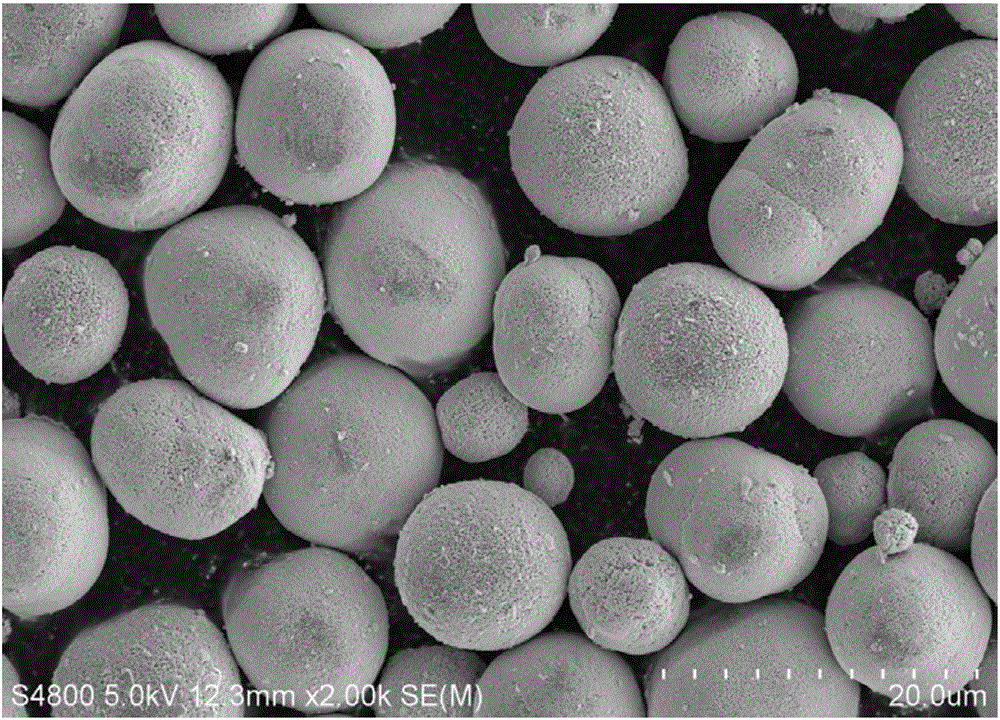

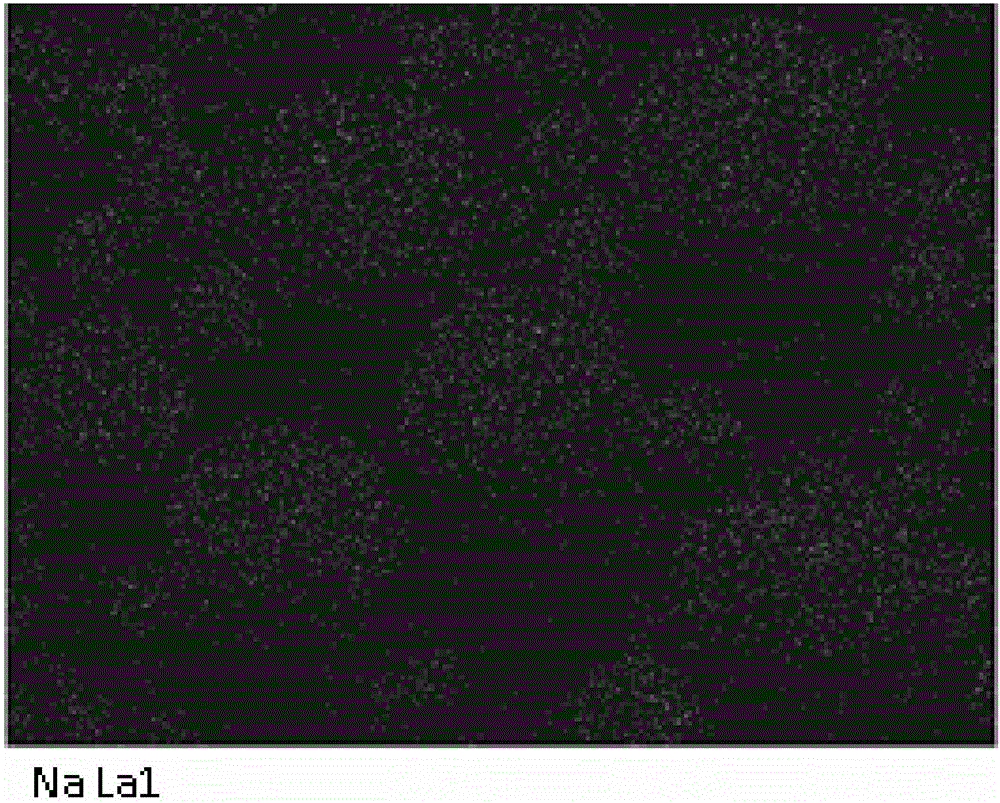

[0027] Specifically, the preparation method of the sodium-doped lithium-rich manganese-based solid solution positive electrode material comprises the following steps:

[0028] Step A, according to the general chemical formula xLi of the lithium-rich manganese-based solid solution cathode material 2 MnO 3 ·(1-x)LiNi a co b mn c o 2 Manganese, nickel and cobalt molar ratio in the manganese, nickel and cobalt salts are mixed together to prepare a metal salt mixed solution with a total concentration of metal ions of 0.5 to 3 mol / L; wherein, 0.2≤x≤0.7, a +b+c=1, 0.3≤a≤0.7, 0.2≤c≤0.5. In practical application, the anion of the metal salt mixed solution is at least one of sulfate ion, hydrochloride ion, nitrate ion, acetate ion, that is to say, these metal salts can be sulfate, hydrochloride , nitrate, acetate at least one.

[0029]Step B, using a sodium carbonate solution with a concentration of 0.5-2.5 mol / L as a precipitating agent, adding the metal salt mixed solution and ...

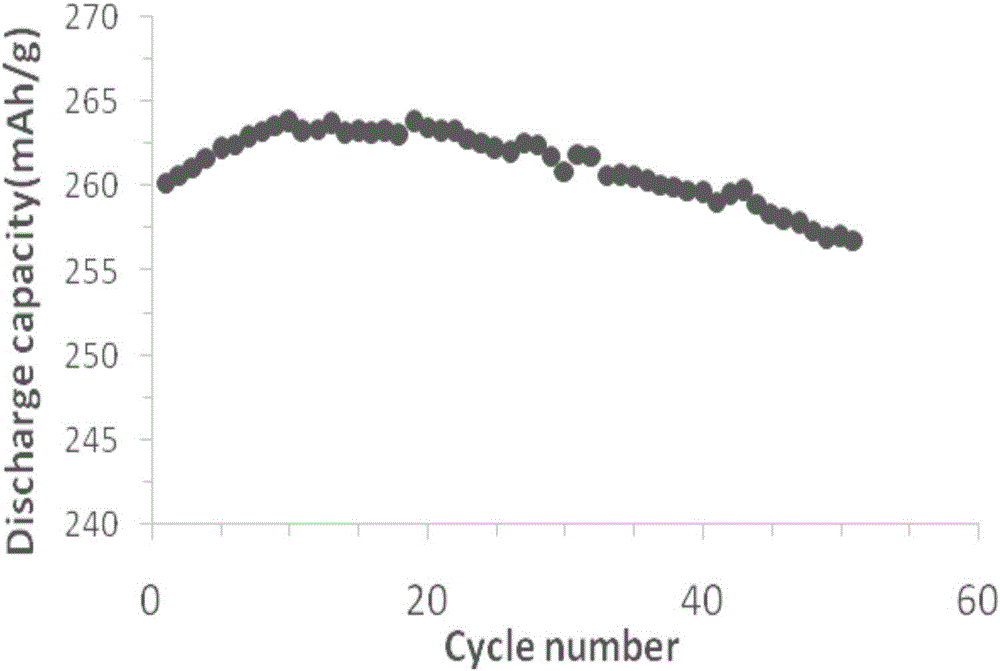

Embodiment 1

[0039] A sodium-doped lithium-rich manganese-based solid solution positive electrode material, the preparation method of which comprises the following steps:

[0040] Step a1, according to the general chemical formula of lithium-rich manganese-based solid solution positive electrode material 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The molar ratio of manganese, nickel and cobalt in the mixture is mixed together with manganese chloride, nickel sulfate and cobalt chloride to prepare a metal salt mixed solution with a total concentration of metal ions of 3mol / L.

[0041] Step b1, using a sodium carbonate solution with a concentration of 0.5mol / L as a precipitating agent, adding deionized water in a reactor with a stirring paddle, so that the ionized water in the reactor has not passed the paddle of the stirring paddle, and then at 800rpm Under the stirring speed, the metal salt mixed solution and the precipitating agent are continuously added to the reaction kettle in p...

Embodiment 2

[0050] A sodium-doped lithium-rich manganese-based solid solution positive electrode material, the preparation method of which comprises the following steps:

[0051] Step a2, according to the general chemical formula of lithium-rich manganese-based solid solution positive electrode material 0.2Li 2 MnO 3 0.8LiNi 0.5 co 0.2 mn 0.3 o 2 The molar ratio of manganese, nickel and cobalt in the solution is mixed together with manganese sulfate, nickel sulfate and cobalt sulfate to prepare a metal salt mixed solution with a total concentration of metal ions of 2mol / L.

[0052] Step b2, using the sodium carbonate solution with a concentration of 1.5mol / L as a precipitant, adding deionized water in a reactor with a stirring paddle, so that the ionized water in the reactor has not passed the paddle of the stirring paddle, and then at 700rpm Under the stirring speed, the metal salt mixed solution and the precipitating agent are continuously added to the reactor in parallel flow, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com