Cu-containing high-conductivity and high-electromagnetic-shielding-property wrought magnesium alloy and preparation method thereof

A deformation magnesium alloy, electromagnetic shielding technology, applied in the field of magnesium alloys, to achieve the effect of increased electrical conductivity, excellent electrical conductivity, good electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

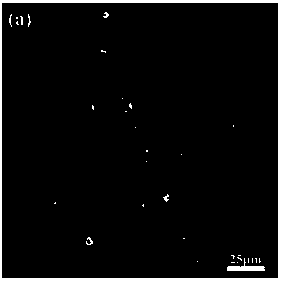

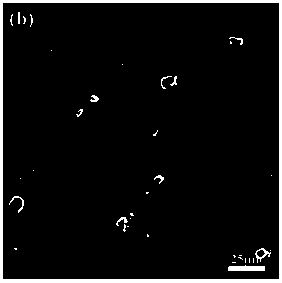

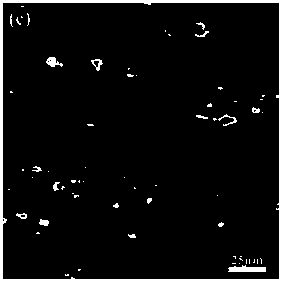

Image

Examples

preparation example Construction

[0038] A method for preparing a Cu-containing deformed magnesium alloy with high electrical conductivity and high electromagnetic shielding performance, the method comprises the steps of:

[0039] a) Melting ingot: in SF 6 +CO 2 Under the protection of gas, put the Mg ingot into the crucible and heat up to 740~760°C after melting, then add pure Zn ingot, Mg-30%Cu, Mg-28.54%Zr master alloy according to the ratio of the above-mentioned magnesium alloy composition; add The method is: preheat the pure Zn ingot, Mg-30%Cu, Mg-28.54%Zr master alloy at 140~220°C for 15~30 minutes, quickly press it into the molten Mg ingot below the liquid level, and after melting Stir, and start refining for 5-10 minutes when the temperature of the melt rises to 750°C. The stirred alloy melt is left to stand at 730-750°C for 10-30 minutes. Casting is carried out in an iron mold, and the casting temperature is 710~730°C;

[0040] b) Homogenization: surface turning the ingot obtained in step a) to re...

Embodiment 1

[0042] Embodiment 1: the Mg-Zn-Zr magnesium alloy containing Cu of the present embodiment, its composition is by weight percentage:

[0043] Zn: 4.96 wt.%;

[0044] Zr: 0.71 wt.%;

[0045] Cu: 0.37 wt.%

[0046] The balance is Mg and unavoidable impurities, the total amount of which is less than 0.06 wt.%.

[0047] According to above-mentioned proportioning and following preparation method, just can obtain the magnesium alloy of the present embodiment:

[0048] a) Smelting ingot: in SF 6 +CO 2Under gas protection, put the Mg ingot into the crucible and heat up to 740°C (or 750°C, 760°C) after melting, and add pure Zn ingot according to the composition ratio of Example 1, Mg-30%Cu, Mg-28.54% Zr master alloy; adding method: preheat the pure Zn ingot, Mg-30%Cu, Mg-28.54%Zr master alloy at 170°C (or 140°C, 210°C) for 25 minutes, and quickly press it into the Mg ingot to melt Below the liquid level after melting, stir after melting, start refining for 5-10 minutes when the me...

Embodiment 2

[0051] Embodiment 2: the Mg-Zn-Zr magnesium alloy containing Cu of the present embodiment, its composition is by weight percentage:

[0052] Zn: 5.01 wt.%,

[0053] Zr: 0.78 wt.%;

[0054] Cu: 0.82 wt.%;

[0055] %。 The balance is Mg and unavoidable impurities, the total amount of impurities is less than 0.06 wt.%.

[0056] The method of smelting ingot-homogenization-hot extrusion to obtain the magnesium alloy of this example is the same as that of Example 1, except that the composition ratio of the smelting alloy is different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com