Novel materials including elements of group 14

A technology of family elements and element cycles, applied in the direction of electrical components, active material electrodes, structural parts, etc., can solve problems such as mechanical and electrical contact damage, achieve good unit mass capacity, and overcome mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0037] According to a first embodiment, the method for preparing a material comprising at least one group 14 element comprises at least one step of thermally decomposing a material represented by the following chemical formula (II) under vacuum conditions:

[0038] wxya

[0039] in:

[0040] - A denotes an alkali metal, especially an alkali metal selected among lithium, sodium and potassium,

[0041] -x represents an integer from 1 to 20, especially an integer from 2 to 15, especially 3 to 12, or even 4 to 10,

[0042] -G means silicon,

[0043] -y represents an integer from 1 to 10, especially an integer from 1 to 6, or even 1 to 4,

[0044] - M denotes a noble or semi-precious metal, especially a noble or semi-precious metal selected among aluminum, cobalt, nickel, copper, zinc, silver, and

[0045] -z represents an integer from 1 to 5, especially an integer from 1 to 3, even 1 to 2.

[0046] This method may be called "thermal decomposition method" or "solid state metho...

no. 2 approach

[0064] According to a second embodiment, the method for preparing a material comprising at least one group 14 element comprises at least the following steps:

[0065] - contacting an oxidizing solvent with a material represented by the following chemical formula (III):

[0066] wxya

[0067] in:

[0068] - A represents at least one alkali metal or alkaline earth metal, especially at least one alkali metal or alkaline earth metal selected among lithium, sodium, potassium, rubidium, magnesium and calcium,

[0069] -x represents an integer from 1 to 12, especially from 1 to 10, especially from 1 to 8,

[0070] - G represents at least one group 14 element, especially at least one group 14 element selected among silicon, germanium, tin and lead, and

[0071] - y represents an integer from 1 to 17, especially from 1 to 15, especially from 1 to 13, and even from 1 to 10, and

[0072] -z is 0,

[0073] - Recovery of A-poor or A-free material.

[0074] As previously stated, when ...

example 1

[0156] Example 1: Alloy Li 13 Ag 5 Si6 preparation of

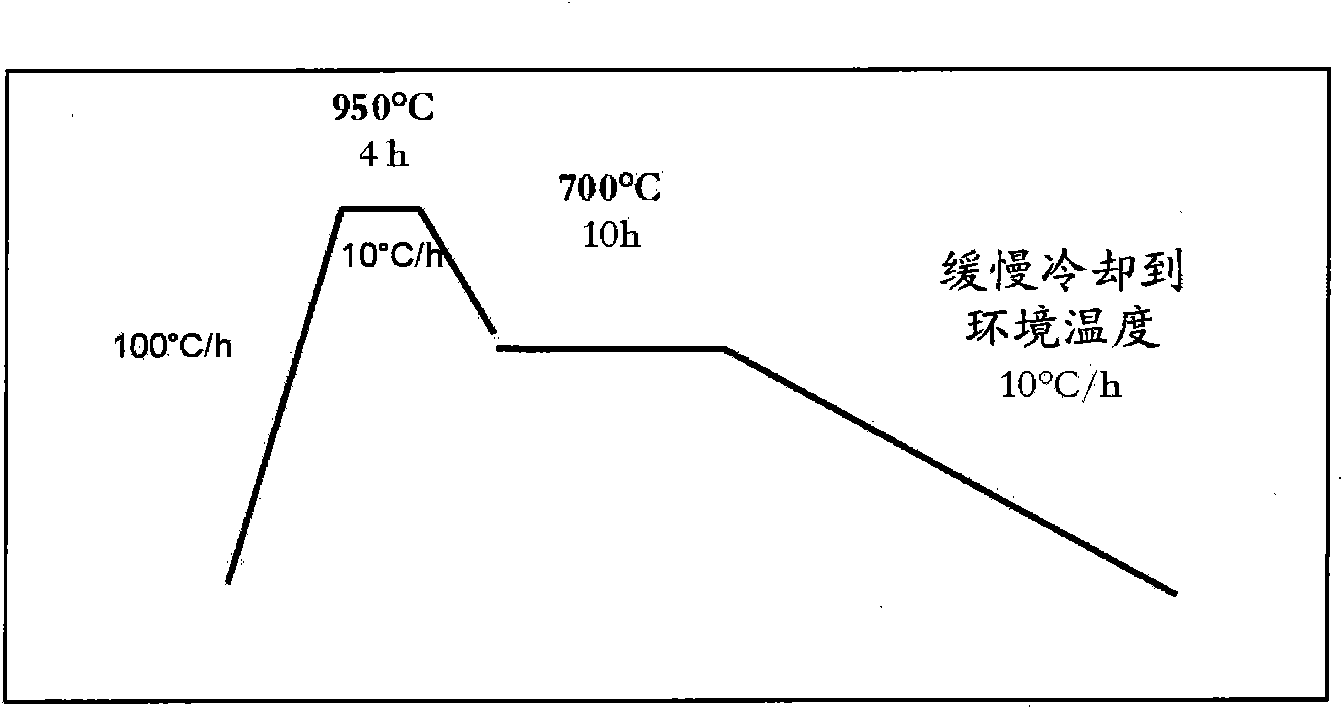

[0157] A mixture of 0.117 grams of lithium (ingot form, 99.54% purity, from Cogema), 0.913 grams of silver (needle form, 99.999% purity, from Strem Chemicals) and 0.237 grams of silicon (powder form, 99.998% purity from Goodfellow) was placed in In a tantalum reactor sealed by arc welding, the tantalum reactor is placed in a quartz tube which is then sealed under vacuum. The reactor was then placed in a furnace, the temperature was raised from ambient temperature to 950°C at a rate of 100°C / h, then maintained at 950°C for 4 hours, cooled to 700°C at a rate of 10°C / h, and at 700°C Heat for 10 hours, then cool to ambient temperature at a rate of 10°C / h. figure 1 Thermal curves are shown graphically.

[0158] A stoichiometric Li 13 Ag 5 Si 6 compound of.

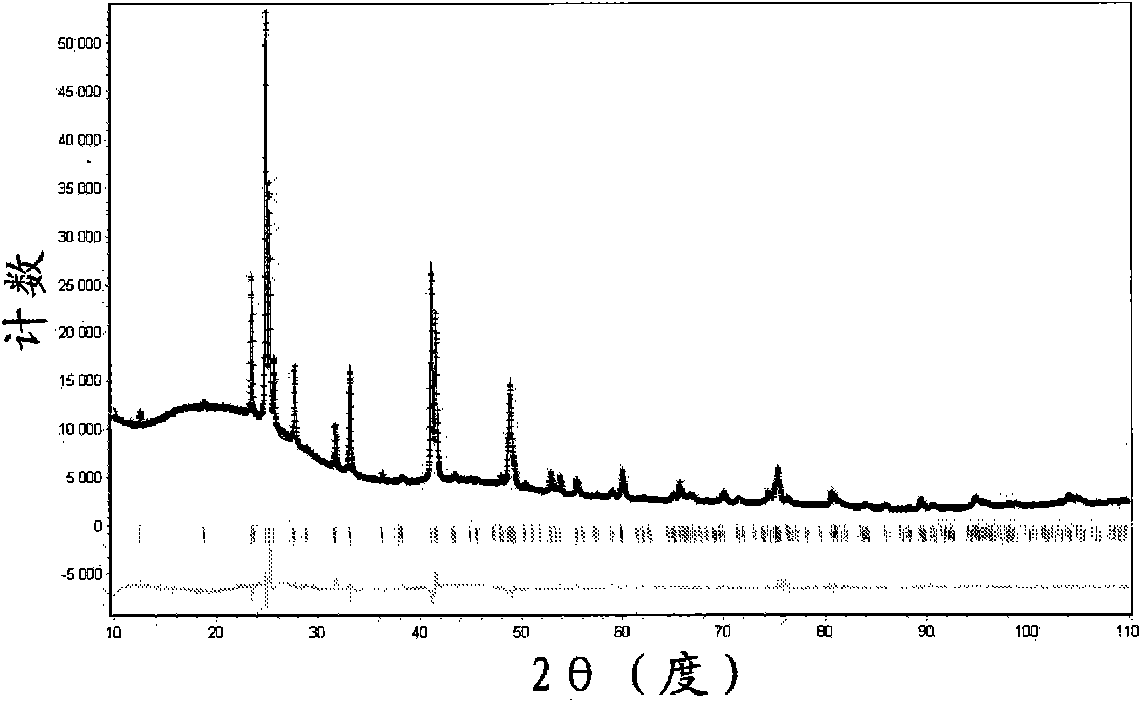

[0159] The compound was studied by X-ray powder diffraction and single crystal diffraction. figure 2 The diffraction pattern of the powder is shown. All peaks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com