In-Sb-Te ternary phase change nanotube and preparation method of array thereof

An in-sb-te, nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve problems such as rare synthesis, achieve high repeatability, low synthesis temperature, and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A pulse cycle parameter is: first deposit at -1.6V for 50ms, then at -1.4V for 50ms, then choose to deposit at -1.3V for 50ms, and finally at -0.4V for 50ms, continue to deposit 30 according to the pulse cycle parameters Minutes, black-gray precipitation can be seen; take out the template with deposits, then dissolve the template with sodium hydroxide solution, and centrifuge repeatedly to completely remove the template. Get the target product.

[0029] The SEM picture of the prepared 200nm In-Sb-Te nanotube array is as follows figure 1 with 2 As shown, it can be seen that the output of the In-Sb-Te nanotube array is large, the length is uniform, up to several microns, and the diameter distribution of the In-Sb-Te nanotube array is very uniform. Example 2:

Embodiment 2

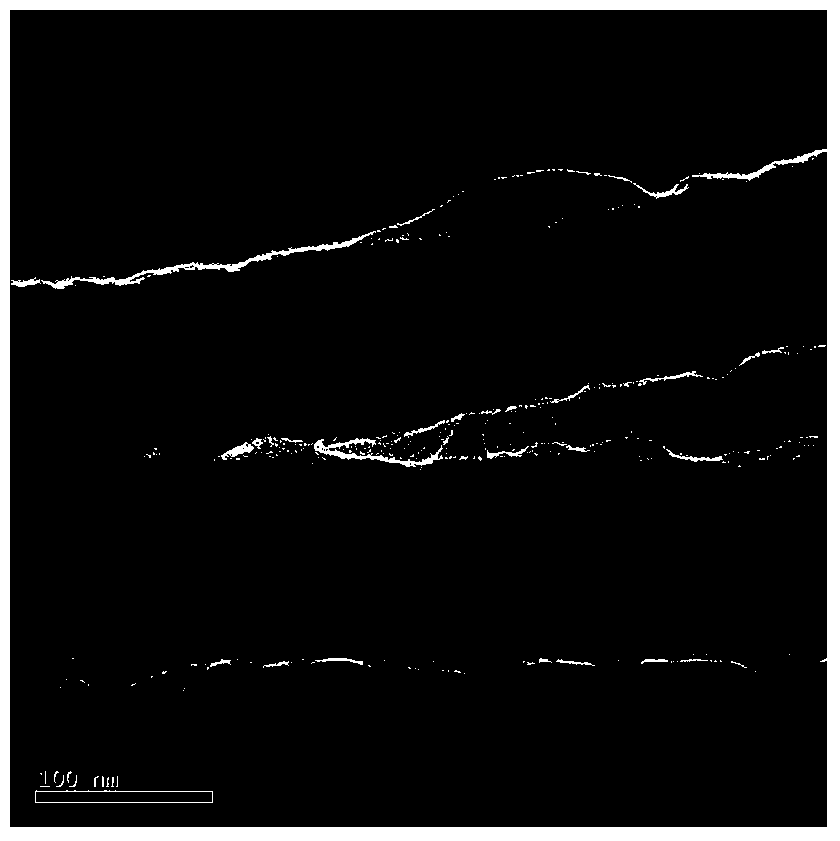

[0030] The steps are the same as in Example 1, except that the alumina template with a pore size of 200 nm is replaced with a polycarbonate (PC) template with a pore size of 100 nm, and other reaction conditions are kept unchanged, and the product is 100 nm In-Sb-Te nanotubes. TEM photos such as image 3 As shown, it is a nanotube structure with a tube wall of about 25nm.

Embodiment 3

[0032] The steps are the same as in Example 1, the difference is that the alumina template with a pore size of 200 nm is replaced with a polycarbonate (PC) template with a pore size of 400 nm, and the deposition time is extended to 1 hour. The other reaction conditions are kept unchanged.

[0033] In-Sb-Te nanotubes.

[0034] Perform energy spectrum eds analysis, the results are shown in the following table, the atomic content ratio of the three elements is 1.91:1.49:1, In 1.91 Sb 1.49 Te, the three elements in the prepared In-Sb-Te nanotubes are uniformly distributed along the axial direction at about 1:1:1, and indeed the tubular structure is distributed along the radial direction at 20-30nm. The content of In, Sb and Te Both decrease and rise again at 70-80nm, and the tube wall is about 25nm.

[0035] Element

[0036] From the reference "SynthesisandCharacterizationofGe2Sb2Te5NanowireswithMemory SwitchingEffect" YeonwoongJung,Se-HoLee,Dong-KyunKo,andRiteshAgarwal*J.AM.CHEM.SOC....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com