Method for determining slag type of molten pool smelting electronic waste and slag type

A technology for e-waste and molten pool smelting, which is applied to the improvement of process efficiency, the use of wave/particle radiation for material analysis, instruments, etc. Simple steps, maintain normal production, and produce clear slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The invention provides a method for determining the slag type of electronic waste smelted in a melting pool, the method comprising the following steps:

[0034] (1) The raw materials come from various types of copper-containing electronic waste collected in the market. After crushing, mixing, and roasting at 650°C, the remaining residue components are analyzed by chemical quantitative analysis and X-ray fluorescence spectroscopy, as shown in Table 1.

[0035] Table 1 The main components of the roasting residue (unit: g / t)

[0036]

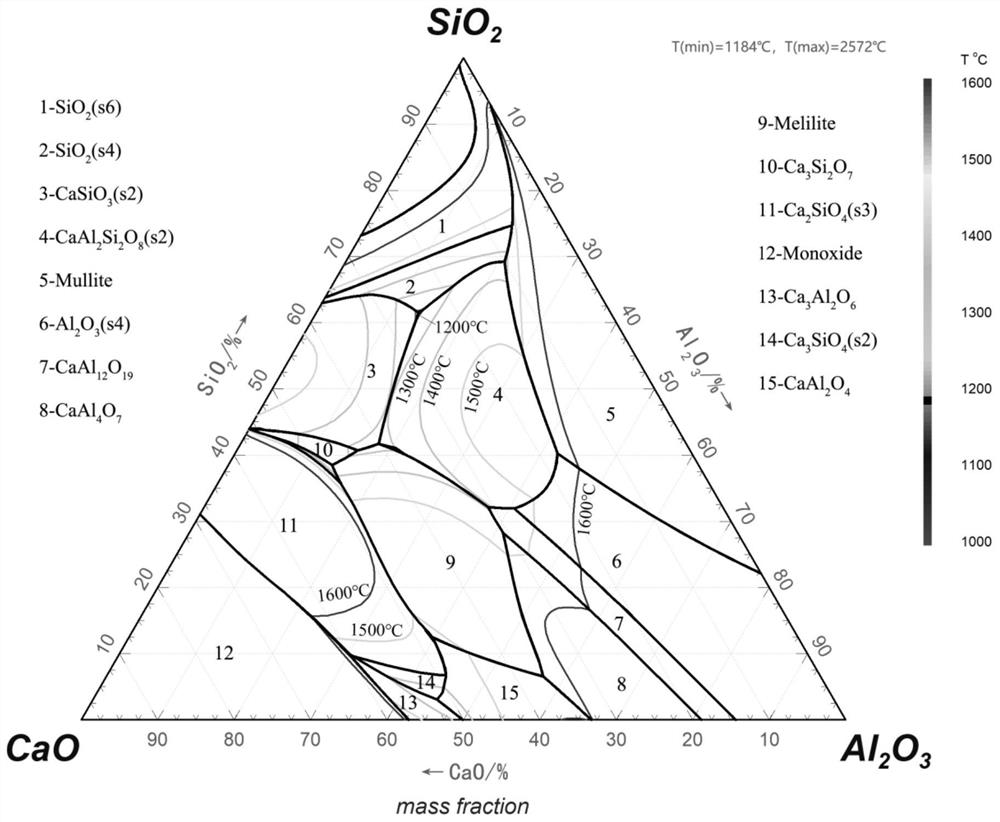

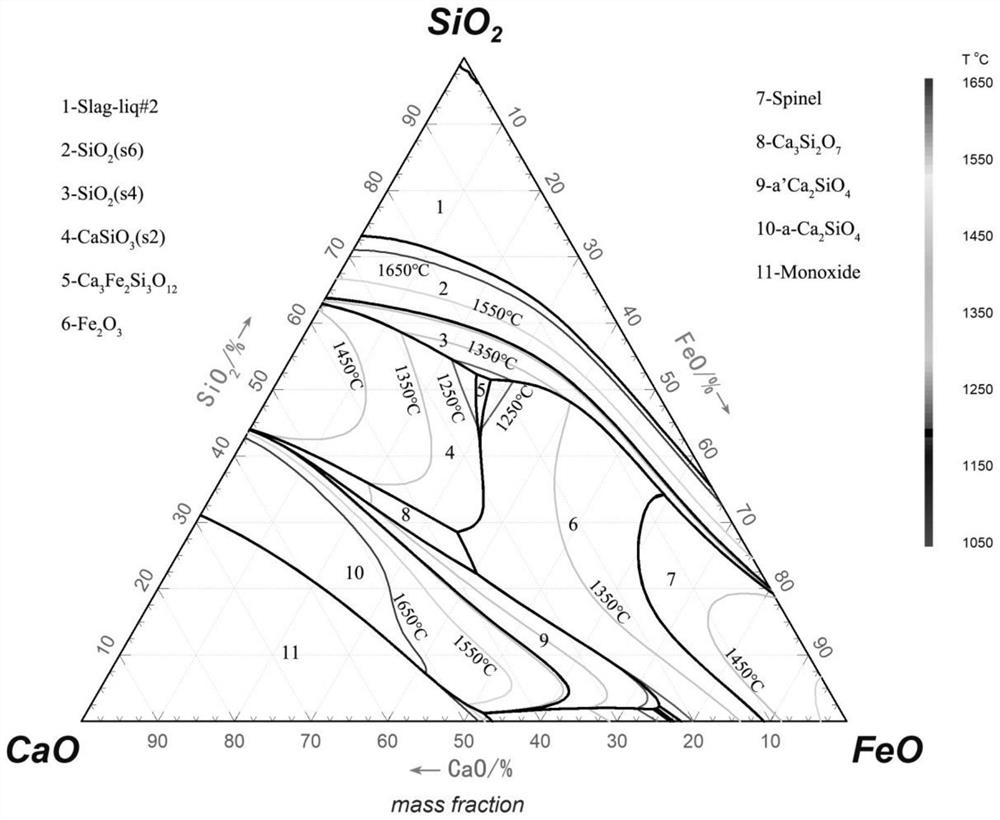

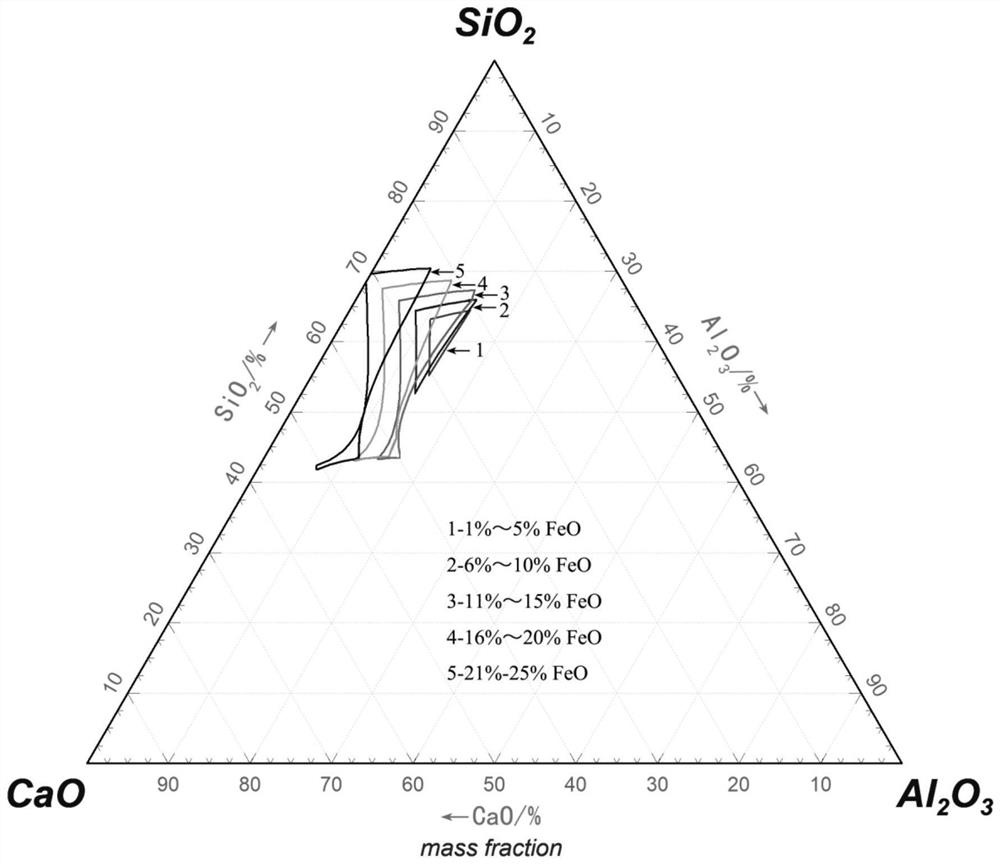

[0037] It can be seen from Table 1 that Al in the waste circuit board roasting residue 2 o 3 Content > 15%, Al 2 o 3 Amphoteric oxide, Al 2 o 3 The presence of Al has a great influence on the viscosity of slag, and Al 2 o 3 The higher the content, the higher the slag melting point and the greater the viscosity. Combined with the phase diagram theory, consider that at 1300 °C, by increasing the solvent, balancing the composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com