Normal temperature cured self-assembly composite nano oxide anti-corrosive paint

A technology of anti-corrosion coatings and oxides, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of increased energy consumption, unstable film formation, poor anti-corrosion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

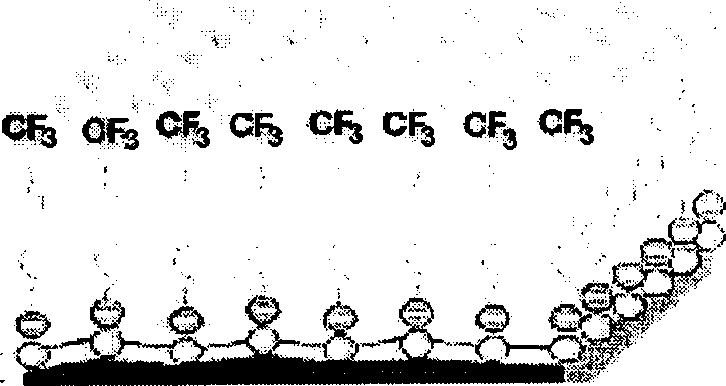

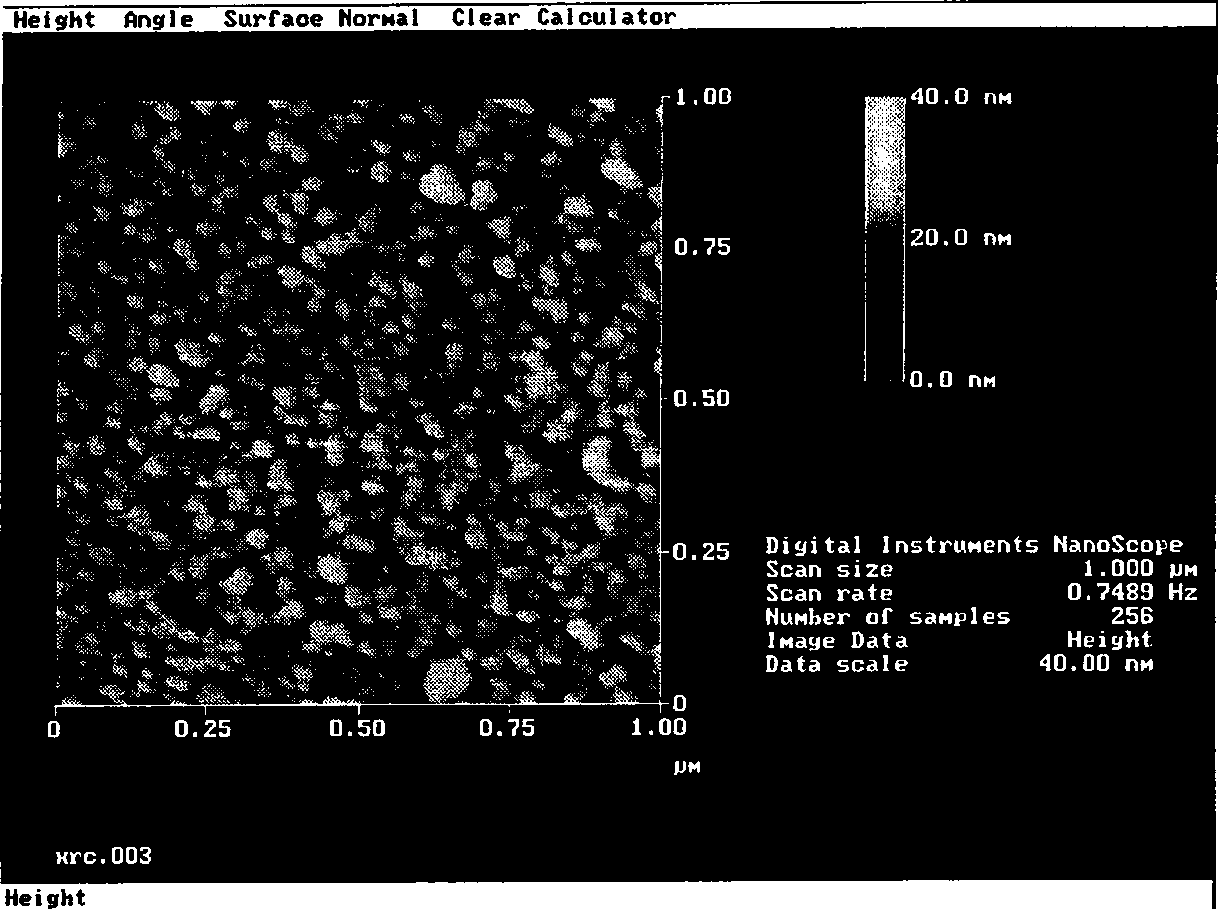

[0037] Dissolve 10 grams of ethyl orthosilicate in 100 grams of absolute ethanol, add 5 grams of 0.5% acetic acid solution, stir at room temperature for 5 hours, add 1 gram of dodecafluoroheptylpropyltrimethoxysilane, N-( β-aminoethyl)-γ-aminopropyltrimethoxysilane 1 gram, continue to stir at normal temperature for 1 hour, because these two silane coupling agents modify the surface of the corresponding nanoparticles, the nanoparticles are self-assembled. A dense coating is formed on the surface of the metal material. The simulated structure and atomic force microscope photos of the nano-anti-corrosion coating are shown in figure 1 , 2 , Nano-particles with uniform particle size self-assembled to form a dense coating. After the sample was cured at room temperature for three days, the salt spray test of the coating on aluminum alloy was up to 70 hours.

Embodiment 2

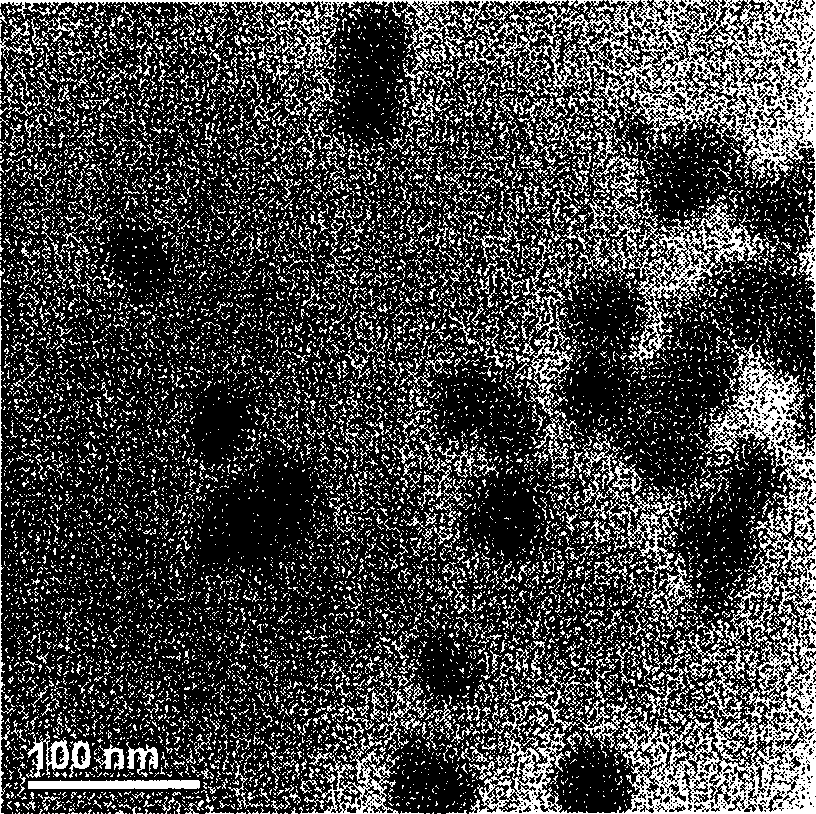

[0039] Dissolve 10 grams of ethyl orthosilicate in 100 grams of absolute ethanol, add 5 grams of 0.5% acetic acid solution, and stir for 5 hours at room temperature. Obtain nano-silica sol. Dissolve 0.6 g of acetylacetone in 10 g of alcohol, then add 2 g of n-butyl titanate, stir for 5 minutes, add 0.2 g of deionized water, and stir for 1 hour to obtain transparent and stable nano titanium dioxide particles uniformly dispersed in the solvent. After mixing the above two sols, add 3 grams of dodecafluoroheptylpropyltrimethoxysilane and 2 grams of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, and continue stirring at room temperature After 1 hour, due to the modification of the surface of the corresponding nanoparticles by the two silane coupling agents, the nanoparticles self-assemble and a dense coating is formed on the surface of the metal material. SEM photo of titanium dioxide nanoparticles image 3 . After the sample was cured at room temperature for three days, the sa...

Embodiment 3

[0041] Dissolve 10 grams of ethyl orthosilicate in 100 grams of absolute ethanol, add 3 grams of 0.5% acetic acid solution, stir at room temperature for 10 hours, add 1 gram of dodecafluoroheptylpropyltrimethoxysilane, N-( 2 grams of β-aminoethyl)-γ-aminopropyltrimethoxysilane, 1 gram of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, because these two silane coupling agents are in the corresponding The modification of the surface of the nanoparticles allows the nanoparticles to self-assemble and form a dense coating on the surface of the metal material. In order to further increase the thickness of the coating, add 2 grams of hydroxyl silicone oil. The scanning electron microscope photo of the nano anti-corrosion coating is shown in Figure 4 . After the sample was cured at room temperature for three days, the salt spray test of the coating on the magnesium alloy material lasted for 50 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com