Material feeding device for drier

A feeding device and drying machine technology, applied in the direction of drying solid materials, dry cargo handling, drying, etc., can solve the problems that wet materials are easy to stick to the stirring rod, and the design of the stirring rod is unreasonable, so as to reduce adhesion and reduce The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

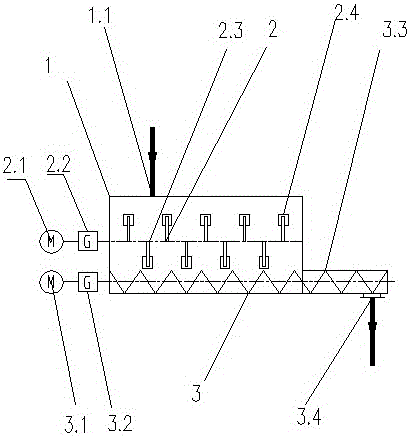

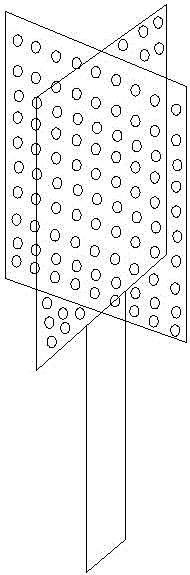

[0014] A feeding device for a dryer, comprising a tank body 1, a stirring device 2 and a feeding device 3, the top of the tank body 1 is provided with a feeding port 1.1, and the stirring device 2 and the feeding device 3 are placed in the tank body 1 Inside, the stirring device 2 is located in the middle of the tank body 1, and the feeding device 3 is located at the bottom of the tank body 1; the stirring device 2 includes a motor A2.1, a reducer A2.2, a transmission shaft 2.3 and a stirring rod 2.4, and the transmission shaft 2.3 One end is connected to the reducer A2.2, and the other end is connected to the bearing on the side wall of the tank body 1. The stirring rod 2.4 is fixed on the transmission shaft 2.3 at an equal distance from top to bottom, and the head of the stirring rod 2.4 is a cross plate; The feeding device 3 includes a motor B3.1, a reducer B3.2 and a feeding screw 3.3, one end of the feeding screw 3.3 is connected to the reducer B3.2, the other end is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com