Excavating type one-time recovery residue film recycling machine

A recycling machine, a one-time technology, applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problems of high cost, low recovery rate, fertility decline, etc., to achieve suitable size plots, high operating efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037] In the present invention, the front end, the rear end and the left and right sides are defined according to the traveling direction of the forward blade 1. Parallel means that the long side of the forward blade 1 is compared with the axes or long sides of other parts. It is only used as a reference, not for reference. to limit the scope of the present invention.

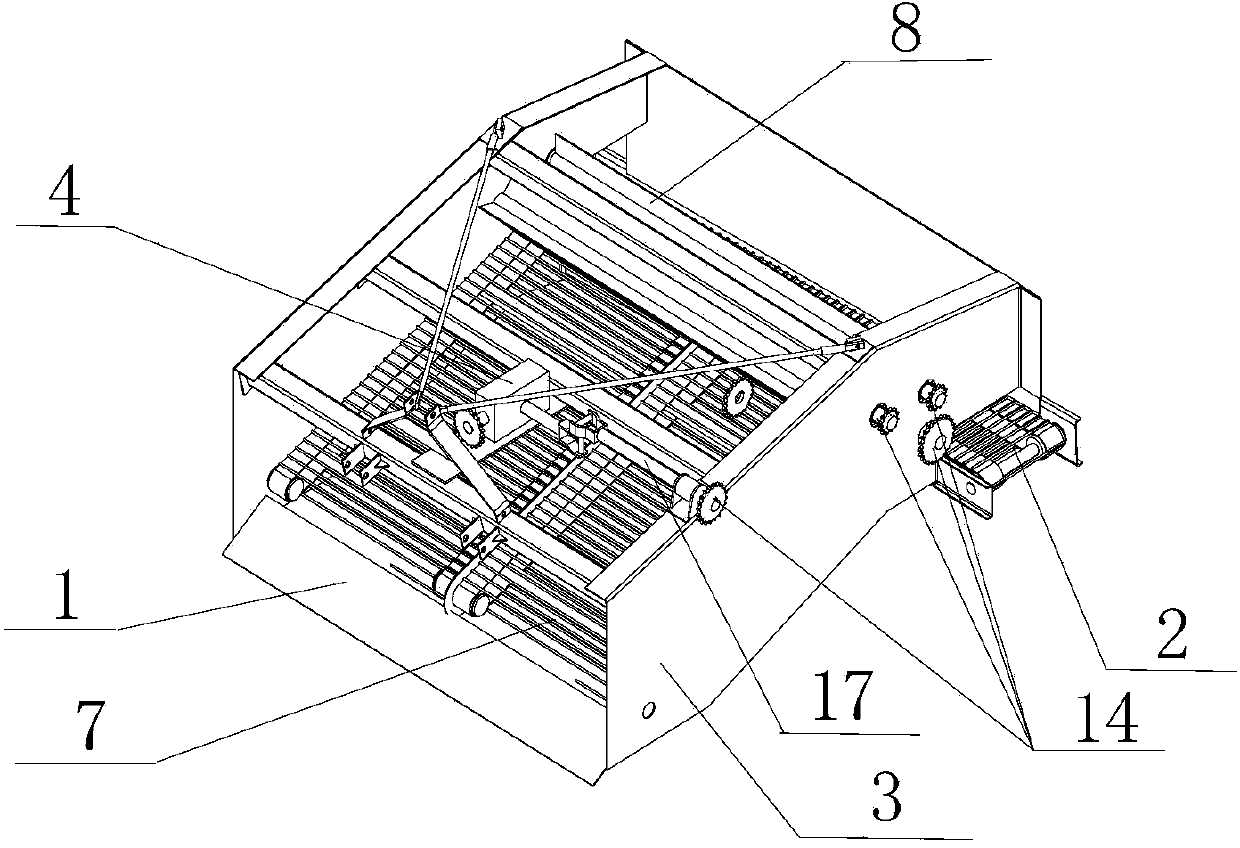

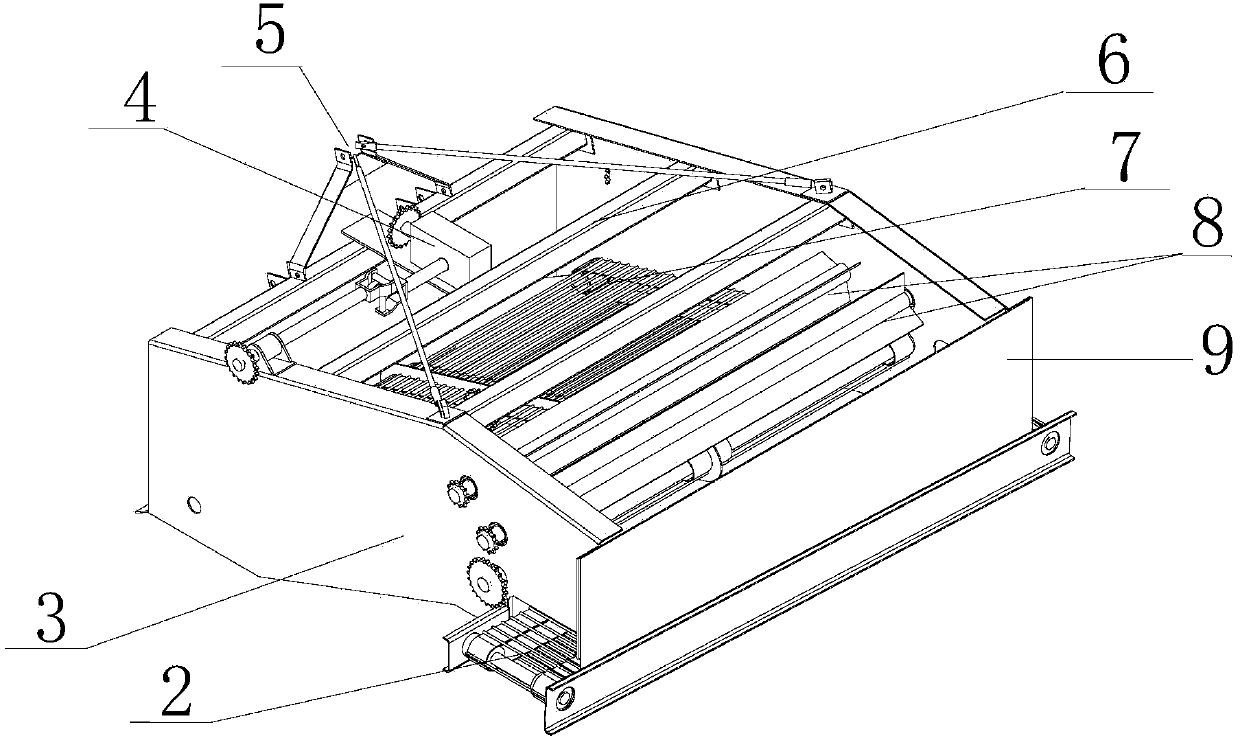

[0038] refer to figure 1 with figure 2 , The present invention includes excavation system, screening system, vibration system, crushing system, separation system, transmission system and leveling system.

[0039] The excavation system includes a forward blade 1 whose blade is a rectangle with a length of 220 cm and a width of 30 cm, and the material is carbon steel.

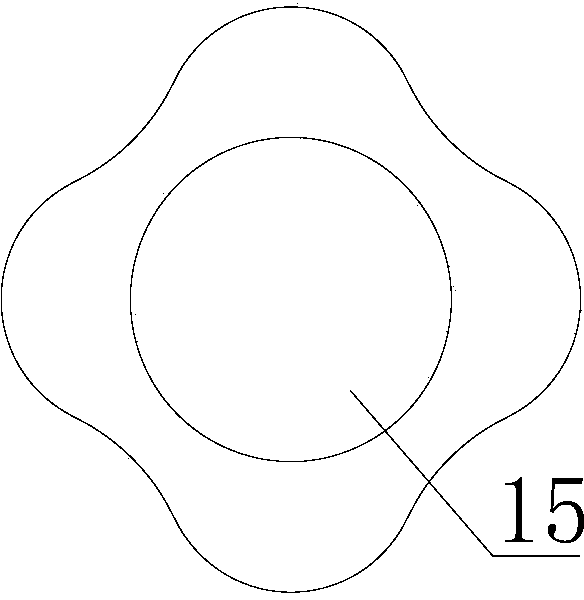

[0040] refer to Figure 9 , The screening system includes two sets of main transfer screens 7 that receive and initially screen wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com