Cleanable demister for oil-gas separator

A technology of demister and demister plate, which is applied in the field of demister, can solve the problems such as not easy to clean, and achieve the effects of easy oil and gas separation, difficult condensation, and simple device principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

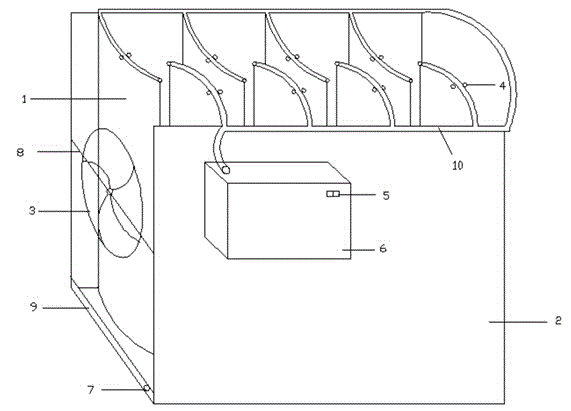

[0010] It is composed of arc-shaped defogging plate (1), structural plate (2), deceleration fan (3), nozzle (4), nozzle control switch (5), cleaning fluid storage tank (6), and drain port (7) , a support rod (8), an oil collection tank (9) and an infusion tube (10), and the deceleration fan (3) installed on the support rod (8) at the front end of the structural plate (2) can effectively reduce the flow rate of the oil mist and reduce the The impact of the oil mist on the arc-shaped defogging plate (1), and the deceleration fan (3) can effectively disperse the oil mist, which is beneficial to the separation of oil and gas. When the oil mist passes through the arc-shaped defogging plate (1), the oil will continuously form small droplets and flow into the oil collection tank (9) along the arc-shaped defogging plate (1), and finally lead out from the drain port (7). When the device needs to be cleaned, turn on the nozzle control switch (5), and the cleaning liquid will be sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com