Method for purifying carbamide polluted water

A technology for polluting water and urea, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

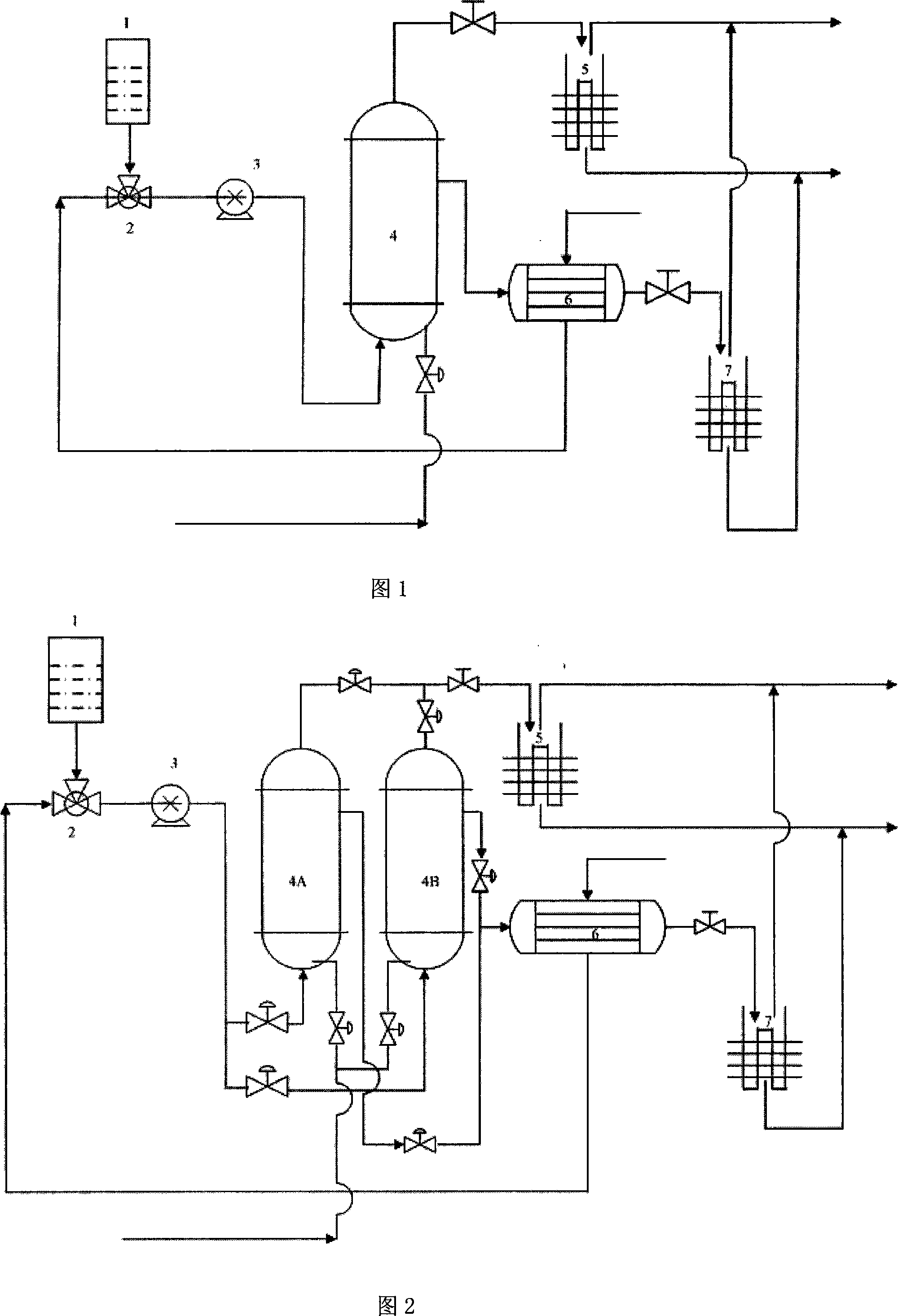

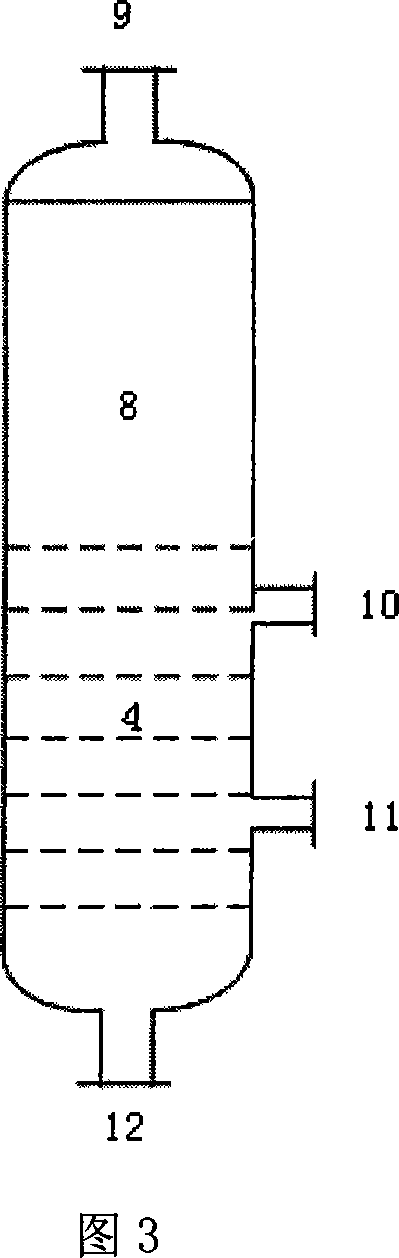

Method used

Image

Examples

example

[0029] The rate of urea-catalyzed hydrolysis is the key to the design of urea desorption water purification process. The following examples further reveal the effectiveness of effective catalysts and their concentrations for water purification by urea hydrolysis.

[0030]Example: Under different reaction conditions, the results of the measured urea hydrolysis rate are listed in Table 1. The urea analysis water is mixed with an appropriate catalyst solution, and the pH value of the reaction solution is adjusted to 14. The hydrolysis reaction is carried out in a high-pressure reactor, and the final reaction temperature is controlled between 100-170°C. The aqueous solution containing the catalyst and urea started to react and was heated for about 12 minutes. The temperature rose from 20°C to 100°C, and then rose to 170°C after 30 minutes. Samples were taken for analysis 30 minutes after the reaction started. For example, the hydrolysis rate at the final reaction temperature of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com