Novel process for producing ammonium tertiary phosphate by using waste ammonia and waste phosphoric acid

A technology of waste phosphoric acid and ammonium phosphate, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of waste ammonia water, waste phosphoric acid, high production cost of ammonium phosphate, polluted water source, environment, etc., to achieve low production cost, Ease of promotion and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

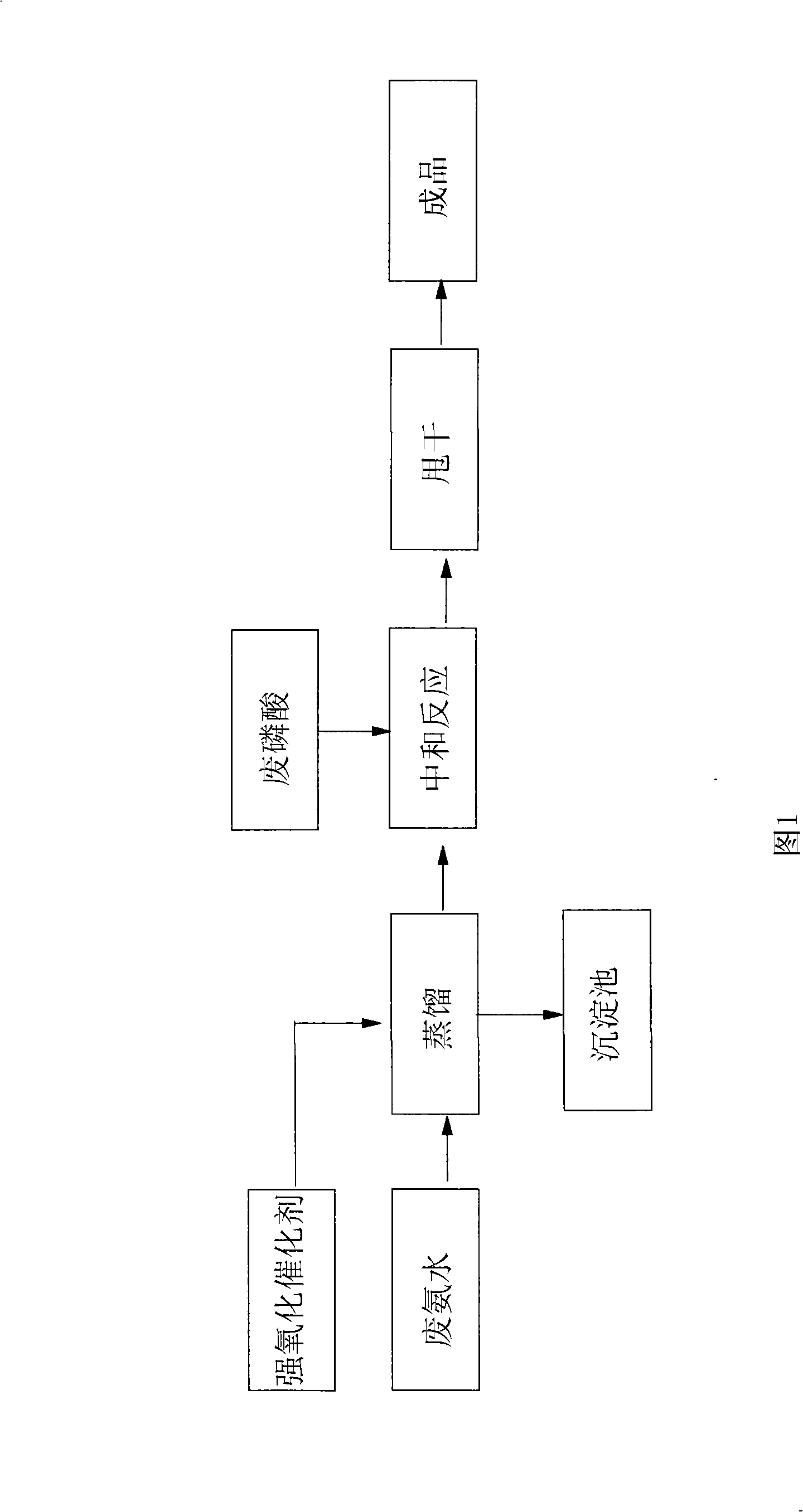

[0013] Process Description

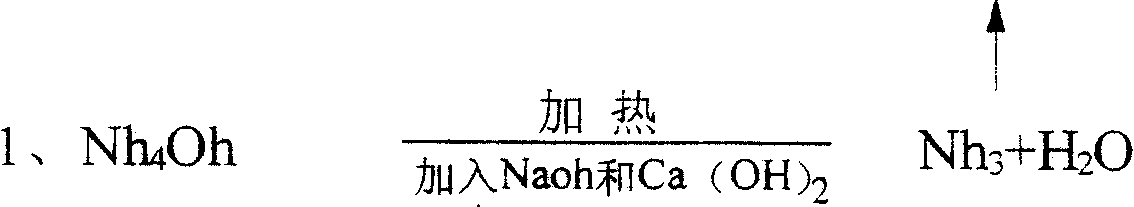

[0014] 1. Raw materials: Waste ammonia water from coking plants, chemical fertilizer plants and chemical plants containing more than 7% of effective ammonia is used. Waste phosphoric acid is waste phosphoric acid containing 25-92% phosphorus from pharmaceutical, electronic and feed processing industries. Strong oxidation catalysts are used. Naoh and Ca(oh) 2 .

[0015] 2. Distillation. Put the waste ammonia water into the distillation axe, add a strong oxidation catalyst, and then heat it to 55-93°C. The ammonia can be decomposed from the waste ammonia water. Stop when the ammonia concentration drops below 0.5%. The waste residue in the distillation ax is discharged into the sedimentation tank, and then new waste ammonia and catalyst are added, and then heated and distilled.

[0016] 3. Neutralization reaction: Pour the waste phosphoric acid into the reaction tank, and pass the distilled ammonia gas directly into the reaction tank for neutralizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com