Sludge treatment device and method

A sludge treatment and sludge technology, applied in dehydration/drying/concentration sludge treatment, fertilization equipment, oxidation treatment sludge, etc., can solve the problems of high cost and energy consumption, high incineration cost, failure to recover available resources, etc. , to reduce costs and improve soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

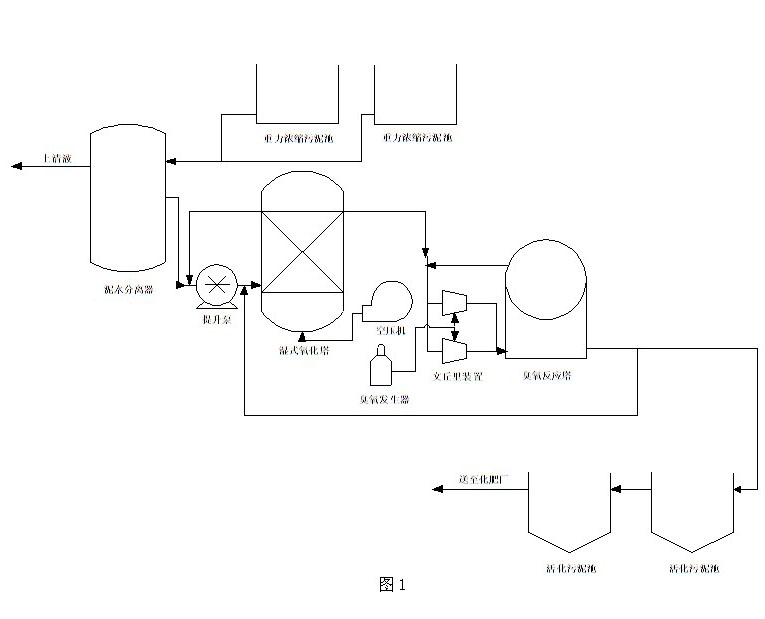

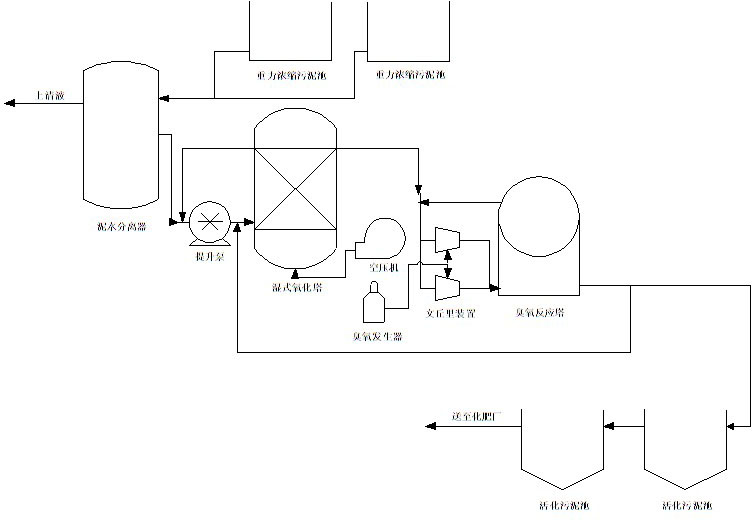

[0017] In this example, refer to figure 1 , The treatment system consists of a wet oxidation system and an ozone oxidation system, two gravity thickened sludge tanks, a common pipe diameter of DN30 (PE material), a return sludge pump power of 1.5kw, and an effective volume of a wet oxidation tower of 4.5 m3.

[0018] The sludge after gravity concentration enters the mud-water separator, and the supernatant enters the sewage treatment system; the sludge is sent into the wet oxidation tower through the lift pump, and the mixer in the wet oxidation tower stirs the sludge, and at the same time, the air compressor sends it into the Preheated air, the preheated air temperature is 150°C (can be 135-165°C), and the residence time is 1 hour (can be stayed for 1-2 hours); heated by electric heating, the wet oxidation tower reaches a temperature of 200°C ( It can be between 150-350°C), the pressure is 4 Mpa (it can be 1-8 Mpa), and it is kept for 60 minutes (it can be 60-80 minutes), int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com