Composite microbial fertilizer for reducing soil pests and diseases of tobacco, and preparation method thereof

A technology of compounding microorganisms, diseases and insect pests, applied in the preparation of organic fertilizers, fertilizers made of biological waste, urea compound fertilizers, etc., can solve the deterioration of farmland ecological environment, unbalanced enrichment of soil nutrients, and decline in production efficiency in tobacco planting areas and other issues to achieve the effect of expelling soil insect pests, enhancing synergistic effects, and reducing insect pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

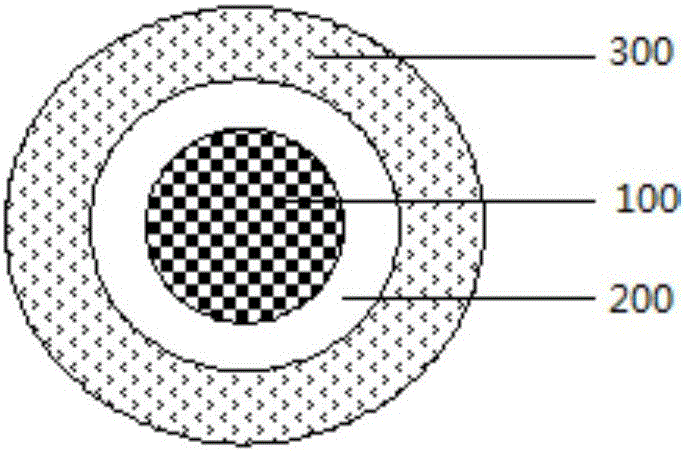

Image

Examples

preparation example Construction

[0020] The preparation method of the above-mentioned compound microbial fertilizer for reducing tobacco underground diseases and insect pests comprises the following steps:

[0021] Step S1 of preparing the inner core: mixing and granulating nitrogen fertilizer, phosphorus fertilizer, potash fertilizer, mineral powder and binder to obtain the first fertilizer granule. That is, the first raw material is mixed and granulated.

[0022] Based on the above, the first raw material includes 8-12 parts by weight of nitrogen fertilizer; 5-9 parts by weight of phosphate fertilizer; 10-14 parts by weight of potassium fertilizer; 4-8 parts by weight of mineral powder; 0.2-0.3 parts by weight of binder.

[0023] Preferably, the nitrogen fertilizer can be urea, the phosphate fertilizer can be monoammonium phosphate, the potash fertilizer can be potassium sulfate, the mineral powder can be bentonite, and the binder can be sodium silicate. These nitrogen fertilizers, phosphorus fertilizers, ...

Embodiment 1

[0045] A method for preparing a compound microbial fertilizer for reducing tobacco underground diseases and insect pests, comprising the steps of:

[0046] S1 prepares the inner core step: Adopt drum granulation equipment to mix and granulate the urea of 8 parts by weight, the monoammonium phosphate of 5 parts by weight, the potassium sulfate of 10 parts by weight, the mineral powder of 4 parts by weight, spray 0.2 parts evenly in the granulation process A sodium silicate solution with a concentration of 15wt% by weight to obtain the first fertilizer granules with a water content of 2wt%;

[0047] S2 Step of preparing the middle layer: using disc granulation equipment to attach 2.5 parts by weight of fly ash and 2 parts by weight of humic acid to the surface of the first fertilizer granule to obtain the second fertilizer granule. The second fertilizer granules are cooled by natural wind, and the moisture content is 8wt%;

[0048] S3 prepares the outer layer step: mix 22 par...

Embodiment 2

[0061] A method for preparing a compound microbial fertilizer for reducing tobacco underground diseases and insect pests, comprising the steps of:

[0062] S1 prepares the inner core step: adopts drum granulation equipment to mix and granulate 12 weight parts of urea, 9 weight parts of monoammonium phosphate, 14 weight parts of potassium sulfate, and 8 weight parts of mineral powder, and evenly spray 0.3 A sodium silicate solution with a concentration of 15wt% by weight to obtain the first fertilizer granules with a water content of 2wt%;

[0063] S2 The step of preparing the middle layer: using disc granulation equipment to attach 4 parts by weight of fly ash and 3 parts by weight of humic acid to the surface of the first fertilizer granule to obtain the second fertilizer granule. The second fertilizer granules are cooled by natural wind, and the moisture content is 8wt%;

[0064] S3 prepares the outer layer step: mixes 30 parts by weight of cow dung and 20 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com