Method of treating oil field waste water by electric-multiphase catalytic reaction and its special equipment

A technology for heterogeneous catalysis and oilfield wastewater, applied in electrochemical water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., to achieve mild reaction conditions, high treatment effect, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

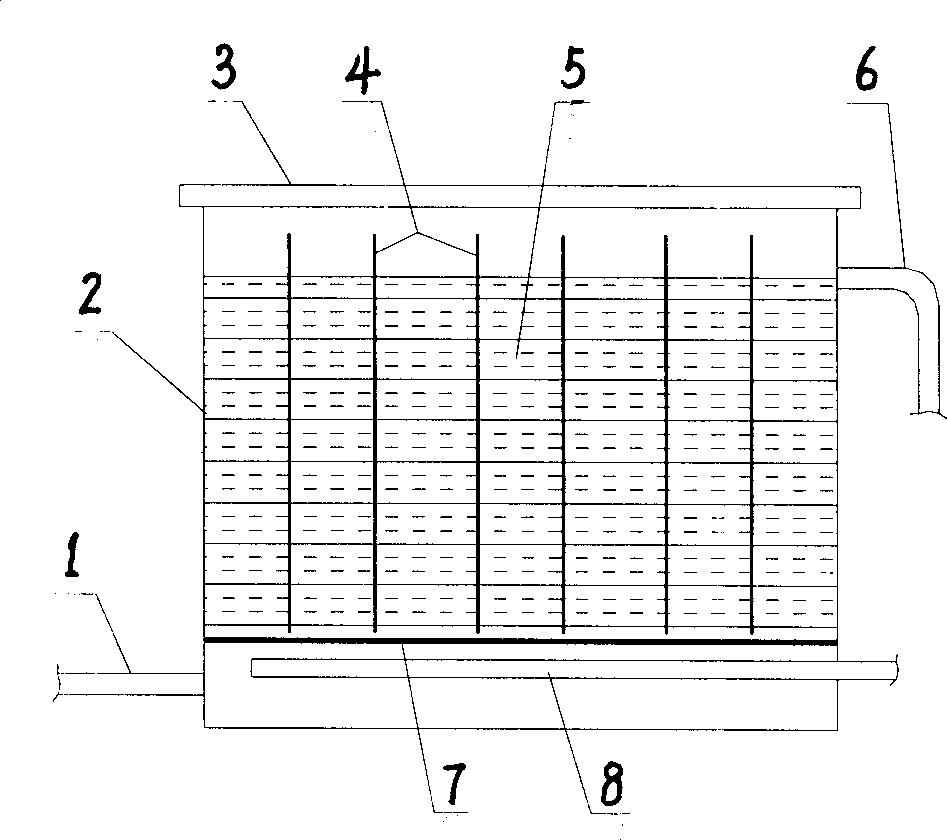

Image

Examples

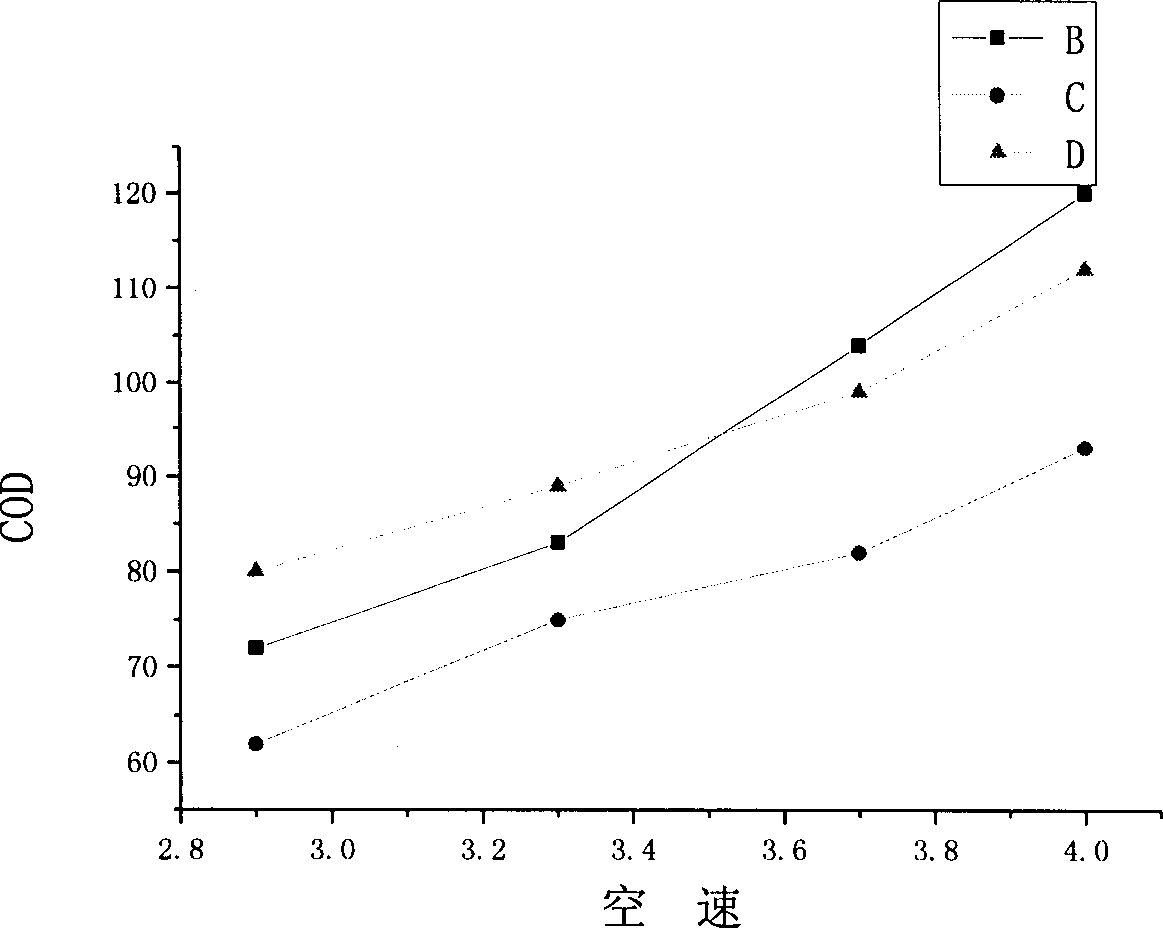

Embodiment 1

[0019] M / SiO 2 Catalyst preparation:

[0020] Take 0.18mol / L of Fe(NO 3 ) 3 Solution 100ml, 100 grams of 40 ~ 60 mesh SiO 2 The particles were poured into the impregnating solution and stirred, left to stand for 10 hours, dried at 110°C for 2 hours, then calcined at 400°C for 3 hours, and naturally cooled to room temperature to prepare Catalyst A. The weight of metal components in catalyst A is: Fe: 1%, the rest is carrier SiO 2 .

Embodiment 2

[0022] M / Al 2 o 3 and preparation of M / zeolite catalyst:

[0023] Take Al 2 o 3 Or molecular sieve zeolite replaces SiO in embodiment 1 2 Particle, all the other are identical with embodiment 1, are prepared to contain Fe: 1% M / Al 2 o 3 Catalyst B or M / zeolite type catalyst C containing Fe: 1%.

Embodiment 3

[0025] Preparation of M / activated carbon catalyst:

[0026] ①Replace SiO in Example 1 with mesoporous activated carbon 2 Powder, and roasting under nitrogen atmosphere, all the other are identical with embodiment 1, are prepared into containing Fe: 1% M / activated carbon type catalyst D1.

[0027] ②Replace SiO in Example 1 with mesoporous activated carbon 2 Powder, and in the impregnating solution in embodiment 1, add the lanthanum nitrate solution 10ml of 0.18mol / L, and in N 2 Roasting under atmosphere, all the other conditions and steps are with embodiment 1. The M / activated carbon catalyst D2 was prepared as La0.2%-Fe1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com