Ground steam power station or chemical and fertilizer plant using underground gas

A technology for thermal power plants and chemical fertilizer plants, which is applied in coal gasification, underground mining, construction, etc. It can solve the problems of wasting chemical raw materials, ground subsidence, and polluting the environment, and achieves the effect of occupying a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

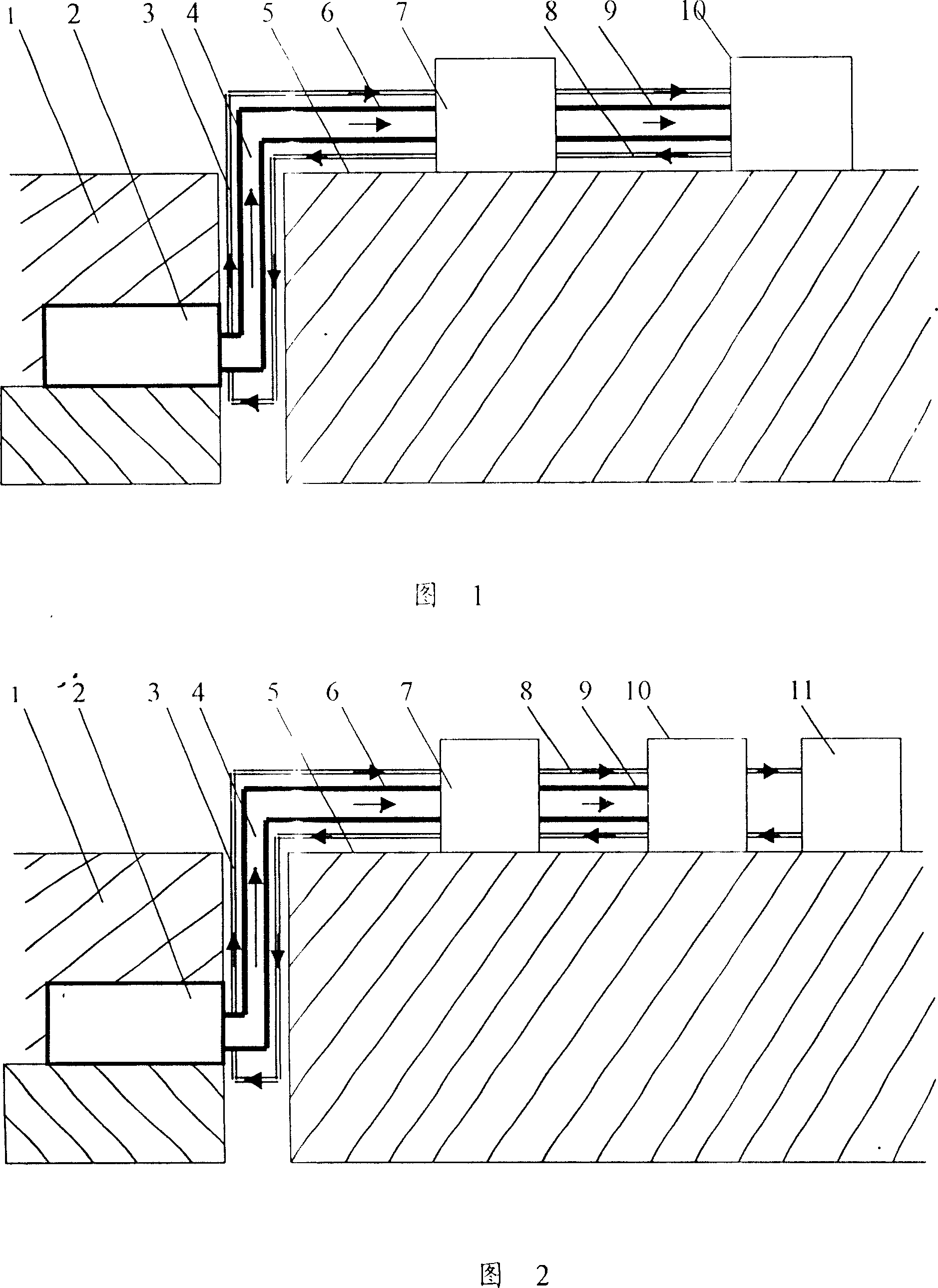

[0011] In Figure 1, the coal gas produced by the underground coal gasification plant is sent to the surface gas treatment plant through pipelines; after desulfurization, dust removal and extraction of coal tar, phenol, ammonia and other chemical raw materials in the gas treatment plant, it is sent to the ground thermal power plant as Fuel; because the gas treatment plant needs to produce coal tar, phenol, ammonia and other raw materials at low temperatures, it is necessary to cool down the gas before it is sent to the gas treatment plant, and arrange a cooling wall composed of cooling water pipes around the hot gas pipeline. After being heated, the cooling Water enters the boiler for power generation.

[0012] In Figure 2, the coal gas produced by the underground coal gasification plant is sent to the surface gas treatment plant through pipelines; after desulfurization, dust removal and extraction of coal tar, phenol, ammonia and other chemical raw materials in the gas treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com