Preparation method for foaming type nutrient composite water-retaining agent

A water-retaining agent and foaming technology, applied in chemical instruments and methods, fertilizer mixtures, organic fertilizers, etc., can solve the problems of industrial production, consumption, and non-use, and achieve good water absorption performance and gel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

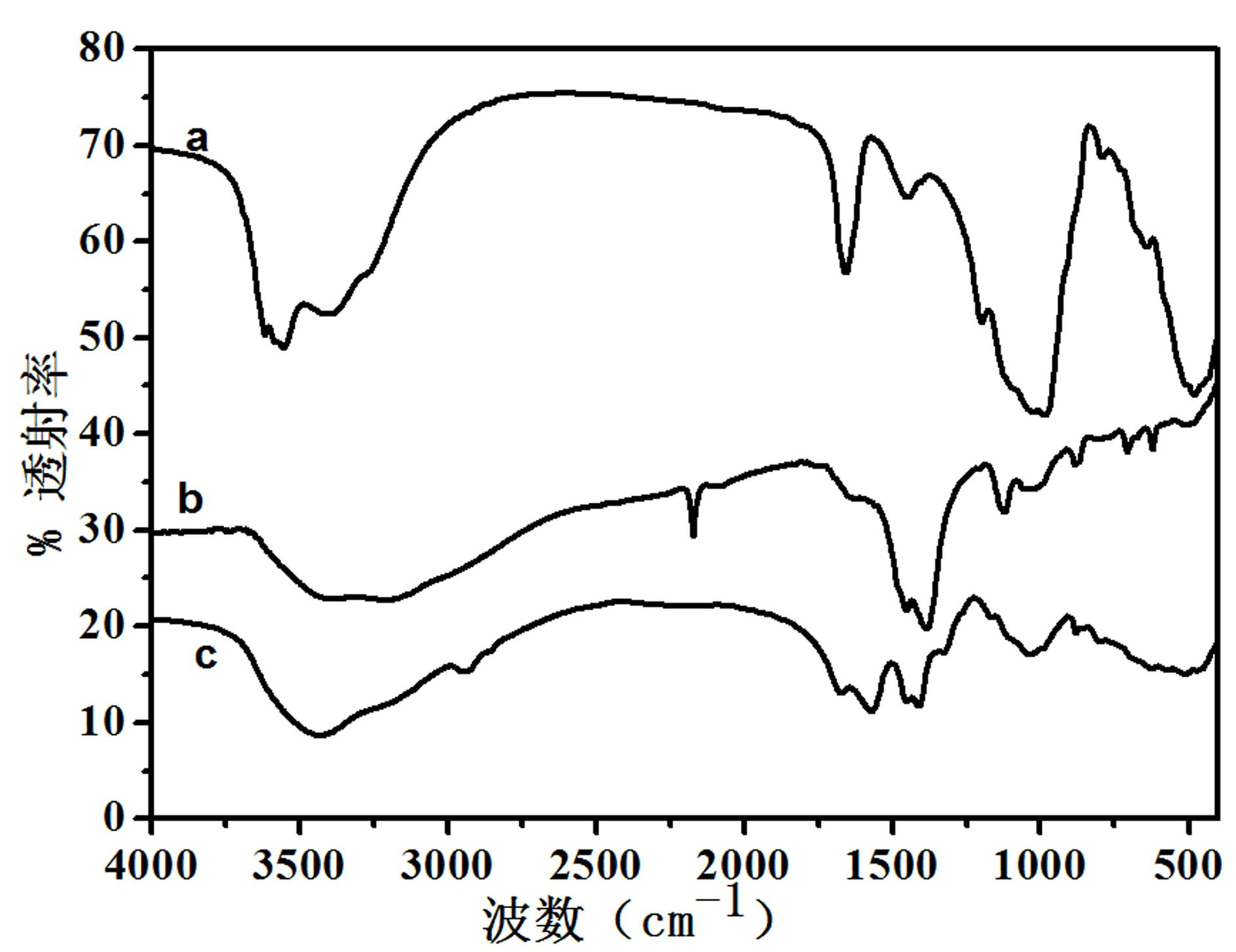

Embodiment 1

[0050] Accurately weigh 5 g of plant ash and add it to a three-necked flask containing 100 ml of distilled water. Under the protection of nitrogen, heat the oil bath to 65℃ for gelatinization for 20 min, then cool to 55℃, add 0.15g initiator potassium peroxodisulfate, and stir for 10 After min, adjust the reaction temperature to 95℃, add 10g acrylamide, 2.5g palygorskite clay ore (montmorillonite-type palygorskite) and 0.035g crosslinking agent (N,N′-methylenebisacrylamide) After reacting for about 30 minutes, 0.25 g of ammonium bicarbonate was added to the reaction system for foaming polymerization, 150ml of 1mol / L mixed solution (sodium hydroxide and potassium hydroxide) was saponified at 75°C for 40 minutes, and then the crosslinked product was taken out. Washing with anhydrous methanol, drying, and pulverizing to obtain a foaming nutritional composite water retaining agent.

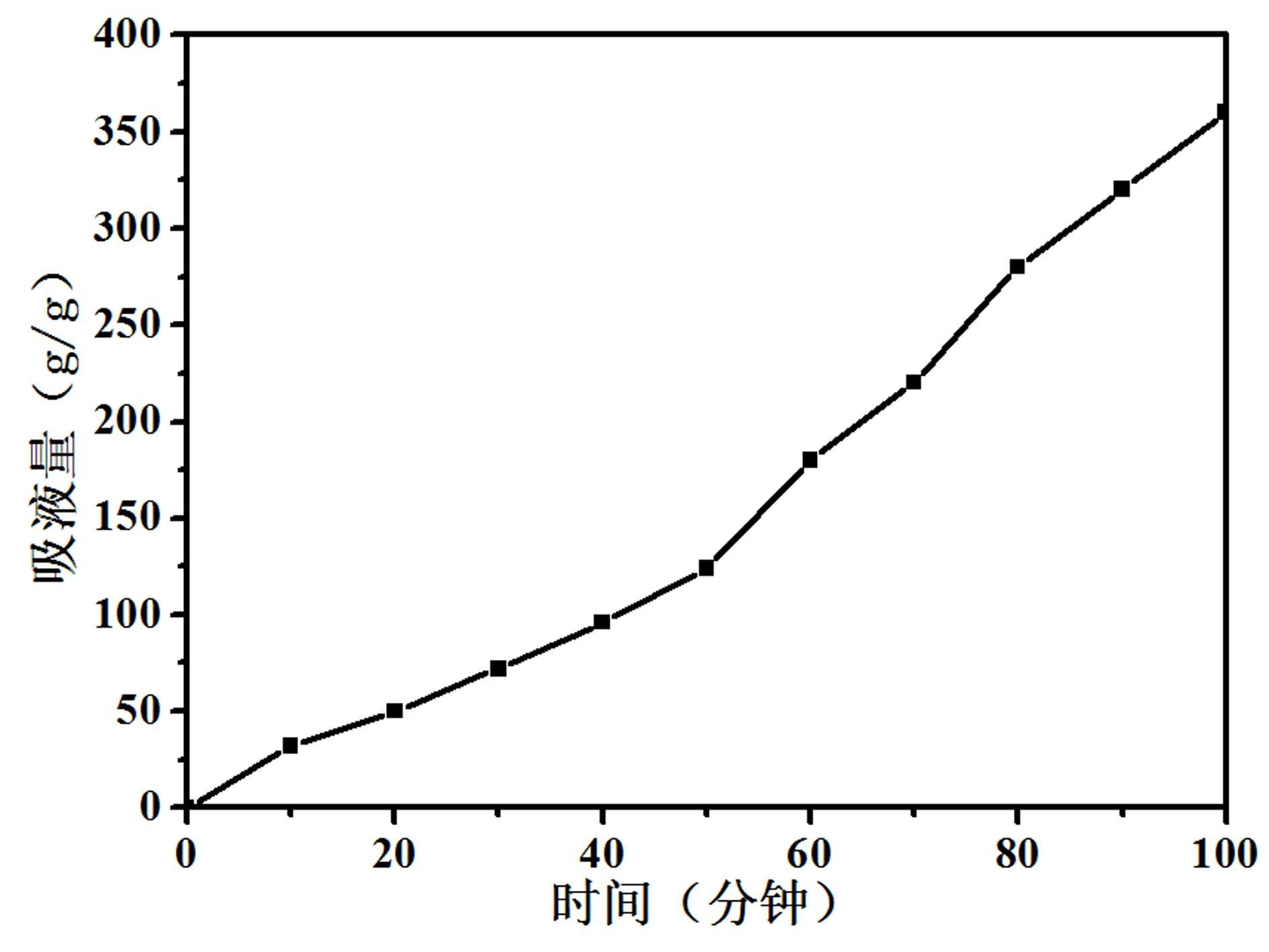

[0051] The composite material obtained by this formula: absorbent distilled water 720 g / g; tap water ...

Embodiment 2

[0053] Accurately weigh 5 g of plant ash and add it to a three-necked flask containing 100 ml of distilled water. Under the protection of nitrogen, heat the oil bath to 70 ℃ for gelatinization for 30 min, then cool to 60 ℃, add 0.20 g of initiator potassium peroxodisulfate, and stir for 10 After min, adjust the reaction temperature to 95℃, add 15 g acrylamide, 3.5 g palygorskite clay ore (dolomite-type palygorskite clay ore) and 0.040 g crosslinking agent (polyethylene glycol bismaleate), After reacting for about 40 minutes, 0.35 g of azoformamide was added to the reaction system for foaming polymerization, 150ml of 1mol / L mixed solution (sodium hydroxide and potassium hydroxide) was saponified at 80 ℃ for 45 minutes, and then the crosslinked product was taken out. Washing with anhydrous methanol, drying, and pulverizing to obtain a foaming nutritional composite water retaining agent.

[0054] The composite material obtained by this formula: water-absorbent distilled water 725 g / ...

Embodiment 3

[0056] Accurately weigh 5 g of plant ash and add it to a three-necked flask containing 100 ml of distilled water. Under the protection of nitrogen, heat the oil bath to 75 ℃ for gelatinization for 40 min, then cool to 65 ℃, add 0.25 g of initiator potassium peroxodisulfate, and stir for 12 After min, adjust the reaction temperature to 95℃, add 20g acrylamide, 4.5g palygorskite clay ore (siliceous palygorskite clay ore) and 0.045g crosslinking agent (N,N′-methylenebisacrylamide), After reacting for about 35 minutes, 0.45 g of ammonium bicarbonate was added to the reaction system for foaming polymerization, 150ml of 1mol / L mixed solution (sodium hydroxide and potassium hydroxide) was saponified at 85 ℃ for 50 minutes, and then the crosslinked product was taken out. Washing with methanol, drying and pulverizing to obtain a foaming nutritional composite water retaining agent.

[0057] The composite material obtained by this formula: absorbent distilled water 734 g / g; tap water 190g / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com