Warehouse type aging preparation method for microbial organic fertilizer

An organic fertilizer and storage-type technology, applied in the field of preparation of microbial organic fertilizers, can solve the problems of incomplete fermentation of organic materials, difficulty in inhibiting the growth of spoilage bacteria, etc., and achieve the effects of simple preparation method, short production cycle and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

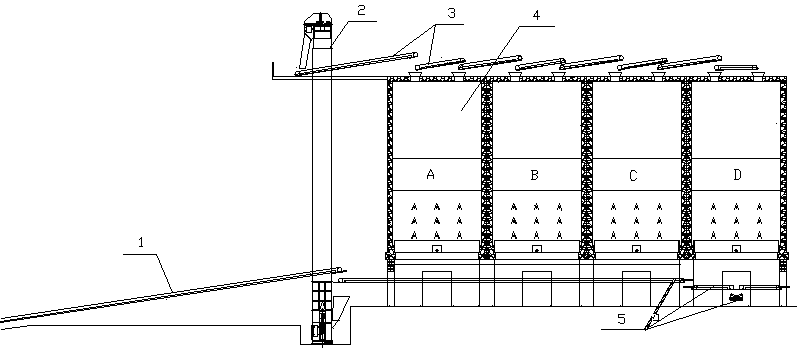

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

[0014] The storage type aging preparation method of this microbial organic fertilizer described in this embodiment is carried out according to the following steps:

[0015] Step 1, organic material pretreatment: pile fresh cow dung in the farm together, and spray microbial deodorant to suppress the odor. After the moisture content is reduced to below 70%, it is transported by vehicle to the fertilizer factory for one time fermentation.

[0016] Step 2, primary fermentation in the fermentation workshop of the fertilizer factory: using a tank-type high-temperature aerobic fermentation process, feeding and discharging materials continuously every day, and feeding 160m3 per day 3 (about 100 tons), cow dung is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com