Testing mould system and its operating method for triaxial experimental disturbed soil testing piece

A triaxial test and test piece technology, which is applied in the direction of basic structure test, material inspection product, construction, etc., can solve the problems of uncontrollable dry density, low preparation efficiency, narrow application range, etc., to reduce manual workload, prepare High efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

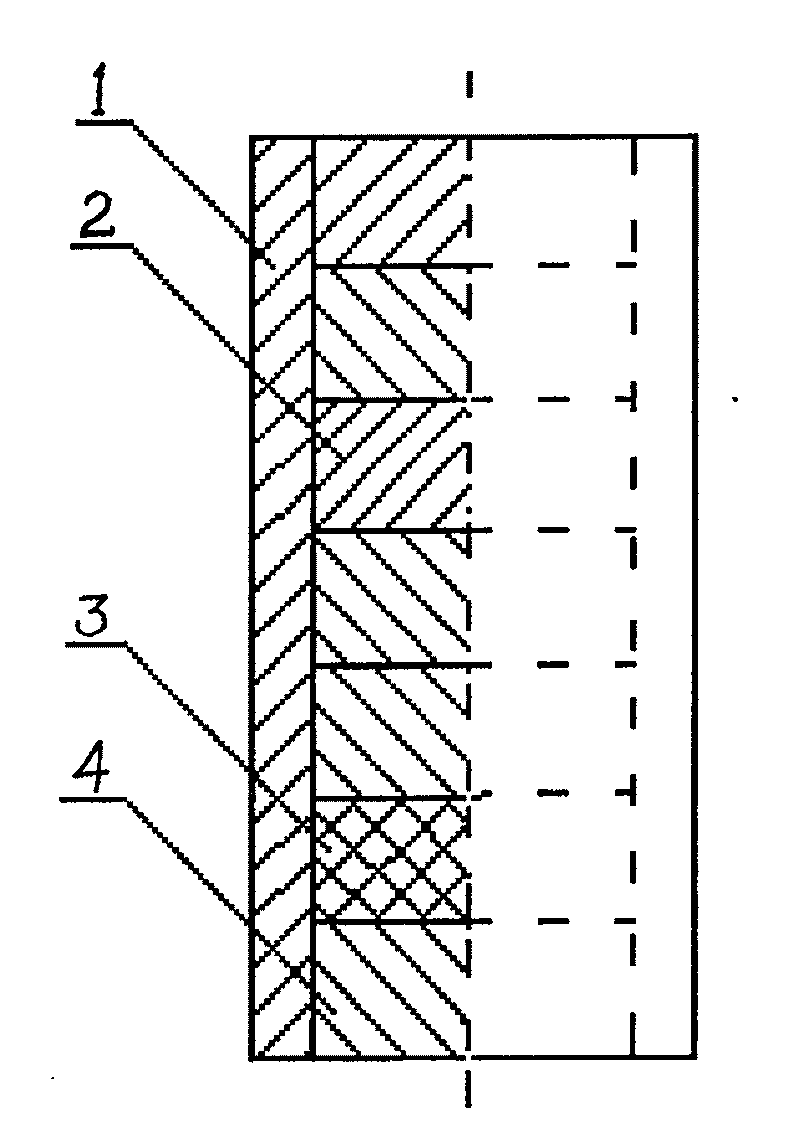

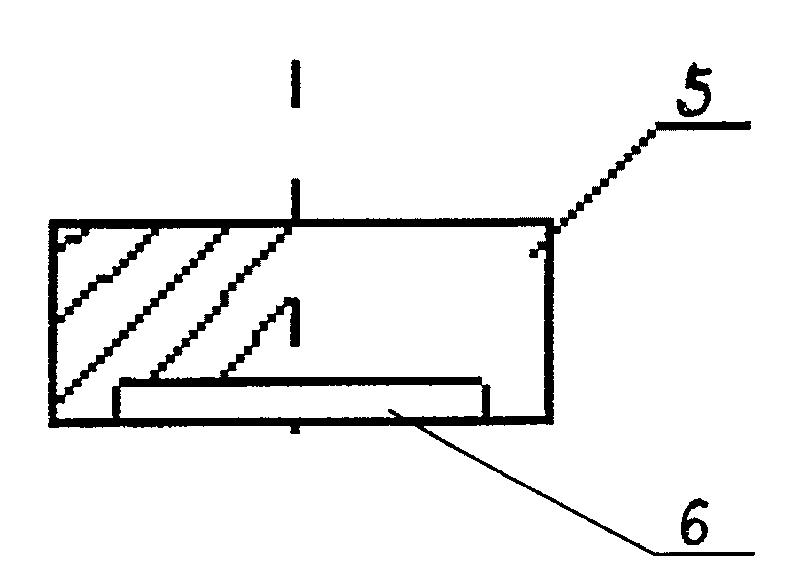

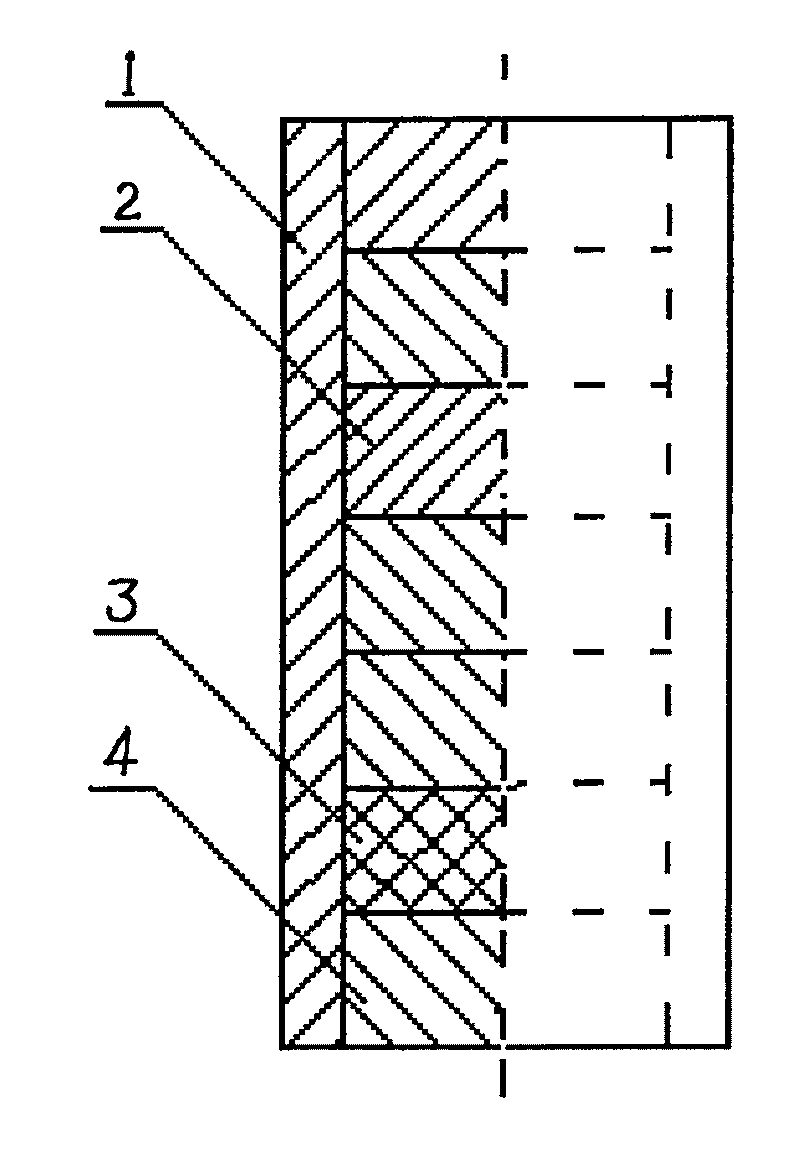

[0039] Example 2, the test mold is composed of a cylinder and a compacting block, wherein the inner diameter of the cylinder is 61.8mm, and the height is 205mm, and there are six compacting blocks, all of which are 61.8mm in diameter, of which there are four The height is 25mm (the same as the height of each layer of the formed sample), and the other two are 40mm, one of which is used as the bottom plate. The total height of the six compacted blocks plus the height of the single-layer soil sample is just equal to the height of the cylinder . The specific operation method of sample preparation is as follows:

[0040] 1. Select the test soil sample, air-dry, crush, and sieve (pass through a 5mm sieve), measure the air-dried moisture content, and calculate the required water amount according to the optimal moisture content of the soil sample.

[0041]2. Spray the amount of water to be added on the soil and mix well, put it in a plastic bag after standing still for a while, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com