A kind of high-capacity cobalt ion intercalation porous manganese dioxide electrode material and preparation method thereof

A technology of manganese dioxide electrode and manganese dioxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve problems such as insignificant effects, unsatisfactory electrochemical properties, and large interface resistance, and achieve production costs The effect of low temperature, short time and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 100mL 0.2mol / L hexaamminecobalt trichloride solution into 3.48mL 5mg / mL manganese dioxide nanosheet dispersion, and stir at room temperature for 6h to obtain hexaamminecobalt ion-intercalated manganese dioxide nanomaterials, Wash, redisperse. Heat the obtained dispersion to 100°C, adjust the pH of the reaction system to 1 with hydrochloric acid, heat to reflux for 2 hours under this condition, cool naturally to room temperature, filter under reduced pressure, wash with deionized water until the filtrate is neutral, freeze-dry, Porous manganese dioxide nanomaterials prepared as cobalt ion intercalation.

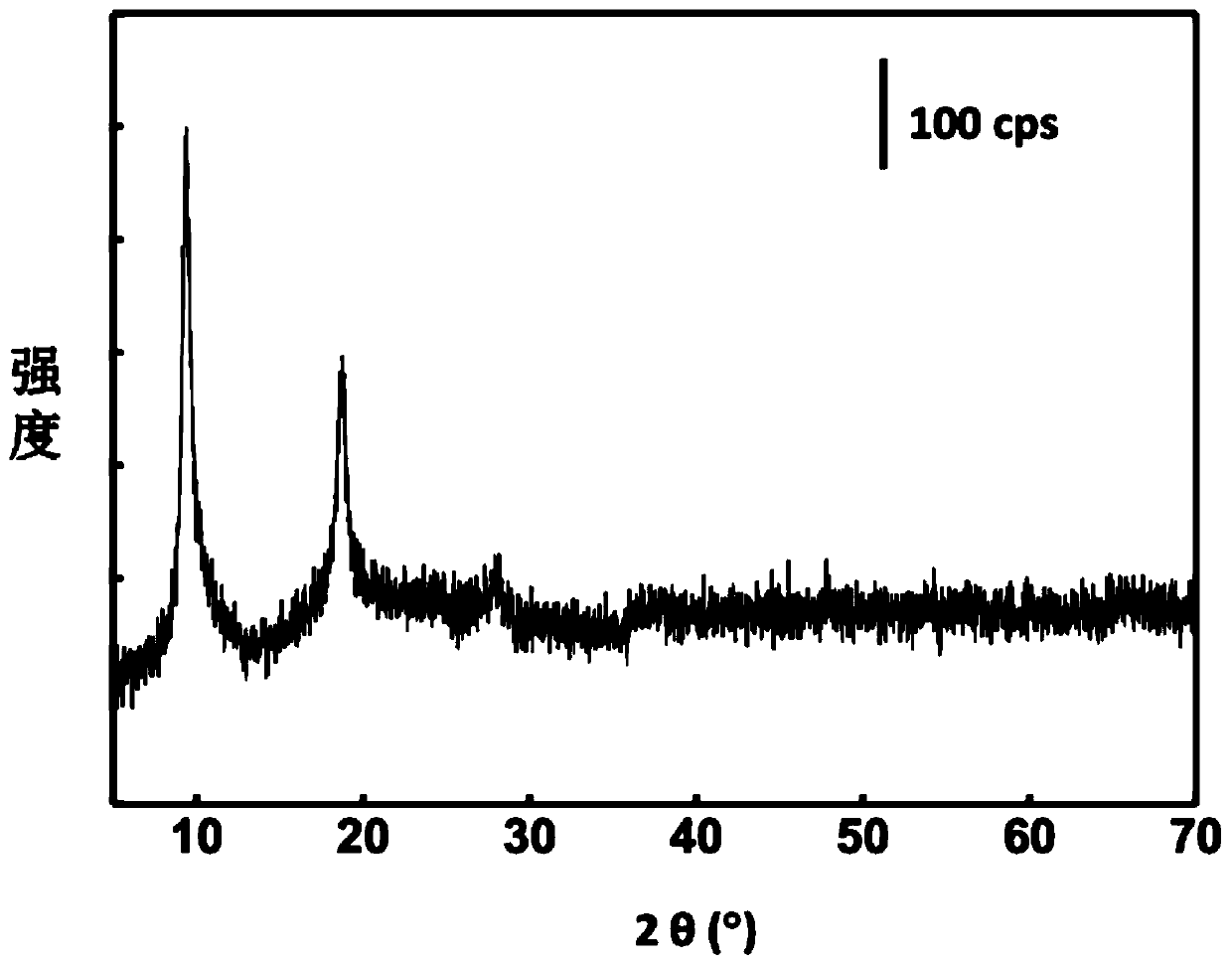

[0036]The obtained product is characterized and tested by X-ray diffractometer, transmission electron microscope and electrochemical workstation, the results are shown in Figure 1~3 . Depend on figure 1 It can be seen from the X-ray diffraction pattern that the resulting product is layered manganese dioxide. From figure 2 It can be seen that the manganese di...

Embodiment 2

[0039] Add 100mL 0.04mol / L cobalt hexammine trichloride solution to the manganese dioxide nanosheet dispersion, and other steps are the same as in Example 1, and the porous manganese dioxide nanomaterial that obtains cobalt ion intercalation is prepared as Figure 5 As shown, tested at a current density of 0.25A·g -1 , its mass specific capacity is 368F·g -1 .

Embodiment 3

[0041] Add 100mL 0.1mol / L cobalt hexammine trichloride solution to the manganese dioxide nanosheet dispersion, and other steps are the same as in Example 1, and prepare the porous manganese dioxide nanomaterials intercalated with cobalt ions such as Figure 6 As shown, tested at a current density of 0.25A·g -1 , its mass specific capacity is 418F·g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com