Method for processing acidity ammonium nitrogen wastewater in fertilizer plant by using membrane separation

A fertilizer plant, acid ammonium technology, applied in the field of high-concentration ammonium-nitrogen wastewater treatment, can solve problems such as increasing treatment costs, secondary air pollution, secondary pollution, etc., and achieve recycling, low operating costs, and floor space. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

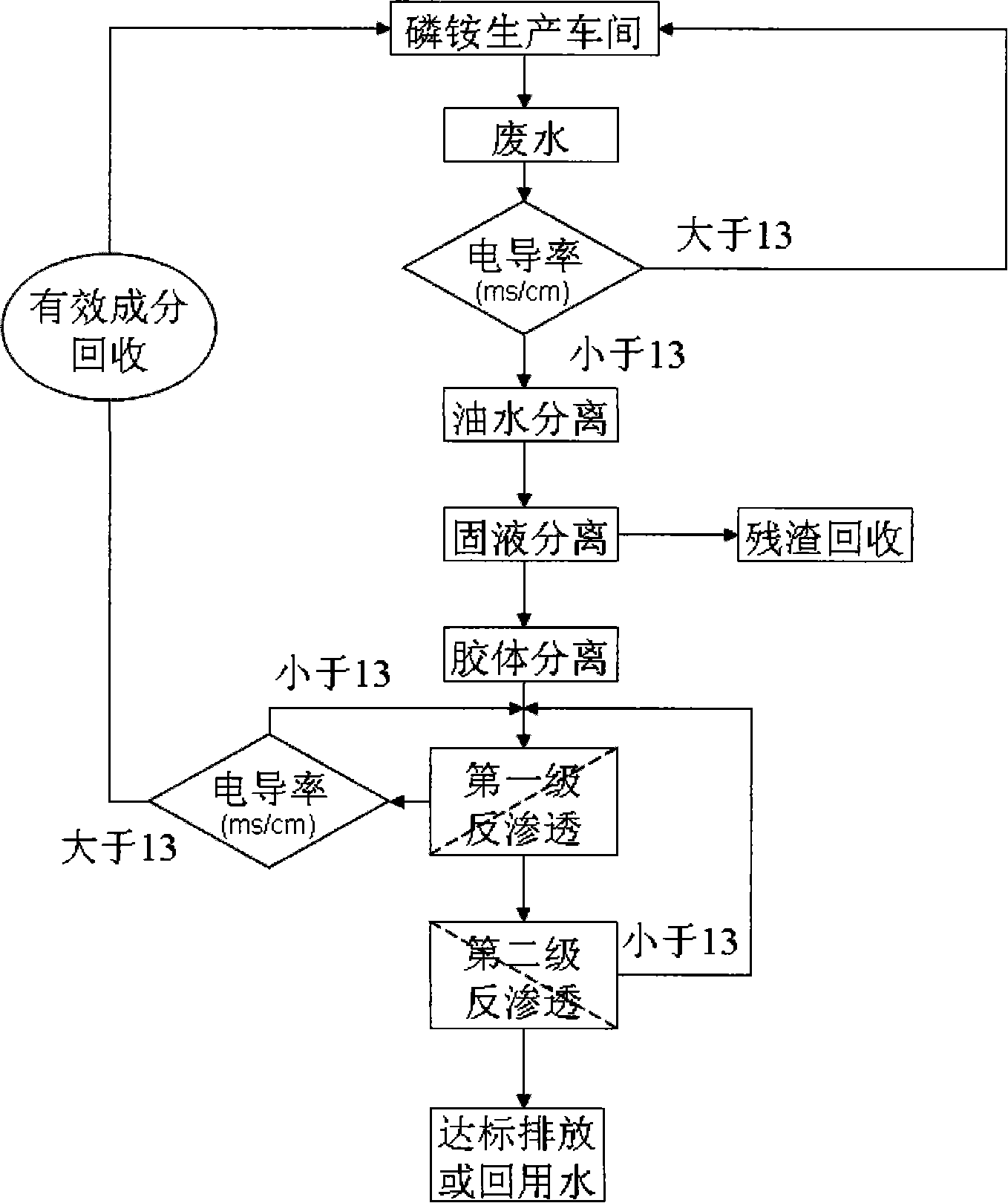

[0028] See accompanying drawing: Utilize the method for membrane separation treatment acid ammonium nitrogen waste water of chemical fertilizer plant, comprise the following steps:

[0029] a. Monitor the conductivity of wastewater (the water quality conditions of wastewater are water temperature: 5-45°C, turbidity (FUT): 50-500, pH value: 2.0-6.0, water-insoluble solid particles: 0-10g / L), if the conductivity If the conductivity is greater than 13ms / cm, it will be pumped back to the ammonium phosphate production workshop for recycling; if the conductivity is less than 13ms / cm, the waste water will be sent to the oil-water separation device with a booster pump, and the waste water after oil separation will be introduced into the 800-mesh The above solid-liquid separation device for filter cloth. The separated solid residue is reused; the waste water after solid residue separation is introduced into the colloidal separation device for microfiltration and ultrafiltration treatme...

Embodiment 2

[0032] See accompanying drawing: Utilize the method for membrane separation treatment acid ammonium nitrogen waste water of chemical fertilizer plant, comprise the following steps:

[0033]a. Monitor the conductivity of wastewater (the water quality conditions of wastewater are water temperature: 5-45°C, turbidity (FUT): 50-500, pH value: 2.0-6.0, water-insoluble solid particles: 0-10g / L), if the conductivity If the conductivity is greater than 13ms / cm, it will be pumped back to the ammonium phosphate production workshop for recycling; if the conductivity is less than 13ms / cm, the waste water will be sent to the oil-water separation device with a booster pump, and the waste water after oil separation will be introduced into a hydrophobic membrane solid-liquid separation device. The separated solid residue is reused; the waste water after solid residue separation is introduced into the colloidal separation device for microfiltration and ultrafiltration treatment. The water qual...

Embodiment 3

[0036] See accompanying drawing: Utilize the method for membrane separation treatment acid ammonium nitrogen waste water of chemical fertilizer plant, comprise the following steps:

[0037] a. Monitor the conductivity of wastewater (the water quality conditions of wastewater are water temperature: 5-45°C, turbidity (FUT): 50-500, pH value: 2.0-6.0, water-insoluble solid particles: 0-10g / L), if the conductivity If the conductivity is greater than 13ms / cm, it will be pumped back to the ammonium phosphate production workshop for recycling; if the conductivity is less than 13ms / cm, the waste water will be sent to the oil-water separation device with a booster pump, and the waste water after oil separation will be introduced into the stack filter install the device. The separated solid residue is reused; the waste water after solid residue separation is introduced into the colloidal separation device for microfiltration and ultrafiltration treatment. The water quality of the treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com