Pretreatment process for oily watewater of cold rolling mill

A pretreatment and wastewater technology, applied in flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Analyzed and other problems to achieve the effect of promoting energy saving, emission reduction and sustainable development, high waste oil recovery rate and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

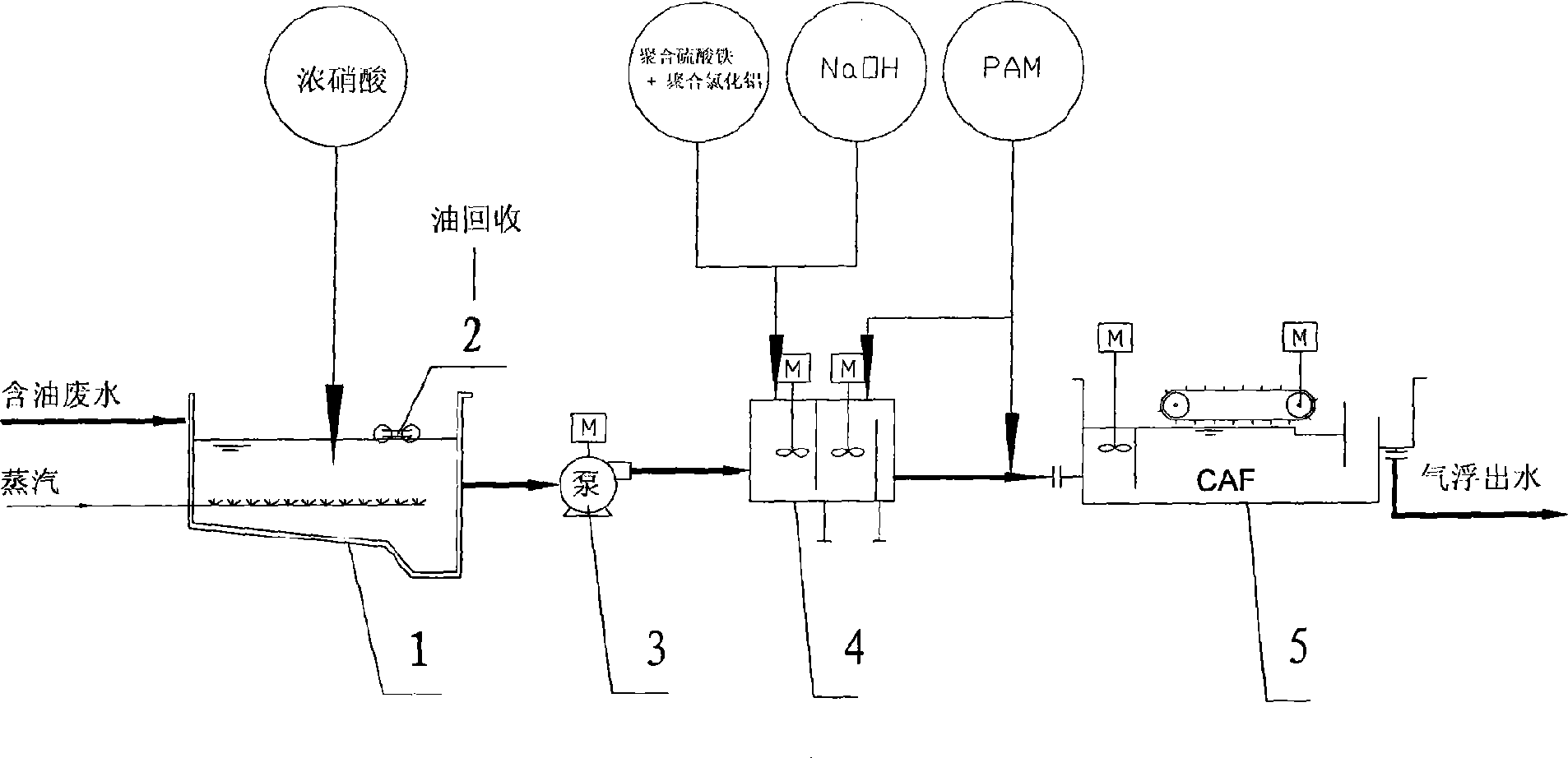

[0025] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0026] refer to figure 1 , the pretreatment process of oily wastewater from cold rolling mills is specifically the following steps:

[0027] (1) oil recovery treatment; feed steam into the regulating tank 1, heat the oily waste water temperature to 60°C-70°C, and add concentrated nitric acid (more than 30% by mass) to adjust the pH between 3.0-4.0, and react 3- 5 hours, collect the oil that floats on the surface of the waste water by the floating oil collection device 2 (oil skimmer);

[0028] (2) Demulsification treatment: pump the waste water after oil recovery treatment into the flocculation tank 4, add sodium hydroxide to adjust the pH at 7.0-8.5, add a composite demulsifier of polyferric sulfate and polyaluminum chloride for demulsification treatment , the mass ratio of the two is 8-12:1, the concentration in the wastewater is 400-800mg / L, and the reaction is stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com