Method and system for treating industrial wastewater of photovoltaic solar cell plates

A technology of solar cells and wastewater treatment system, which is applied in the fields of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect is not ideal and other problems, to achieve the effect of eliminating the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

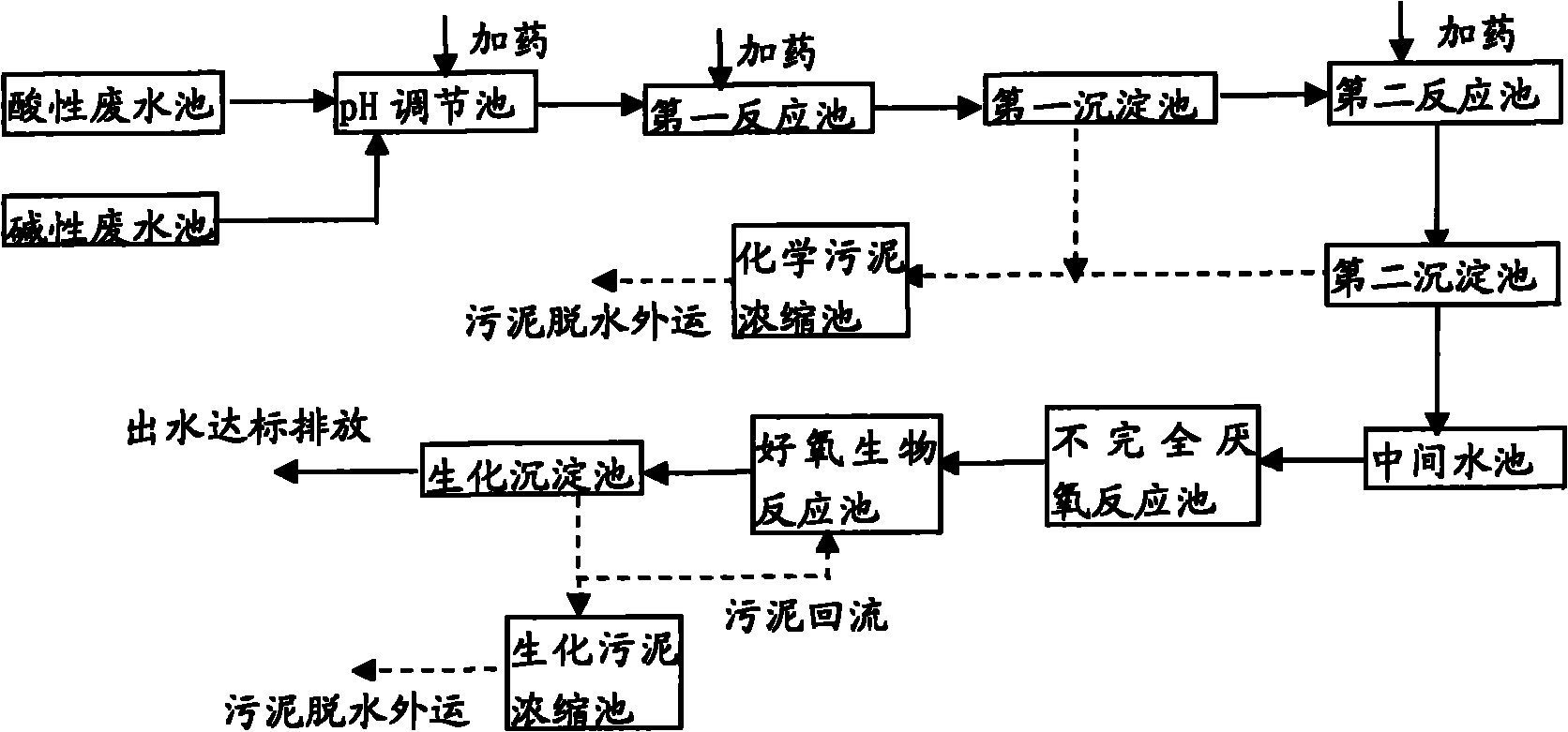

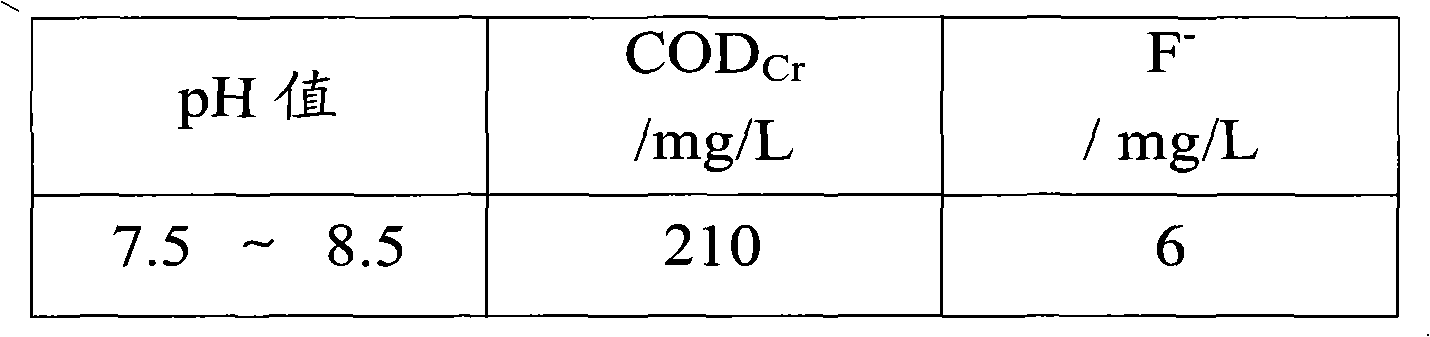

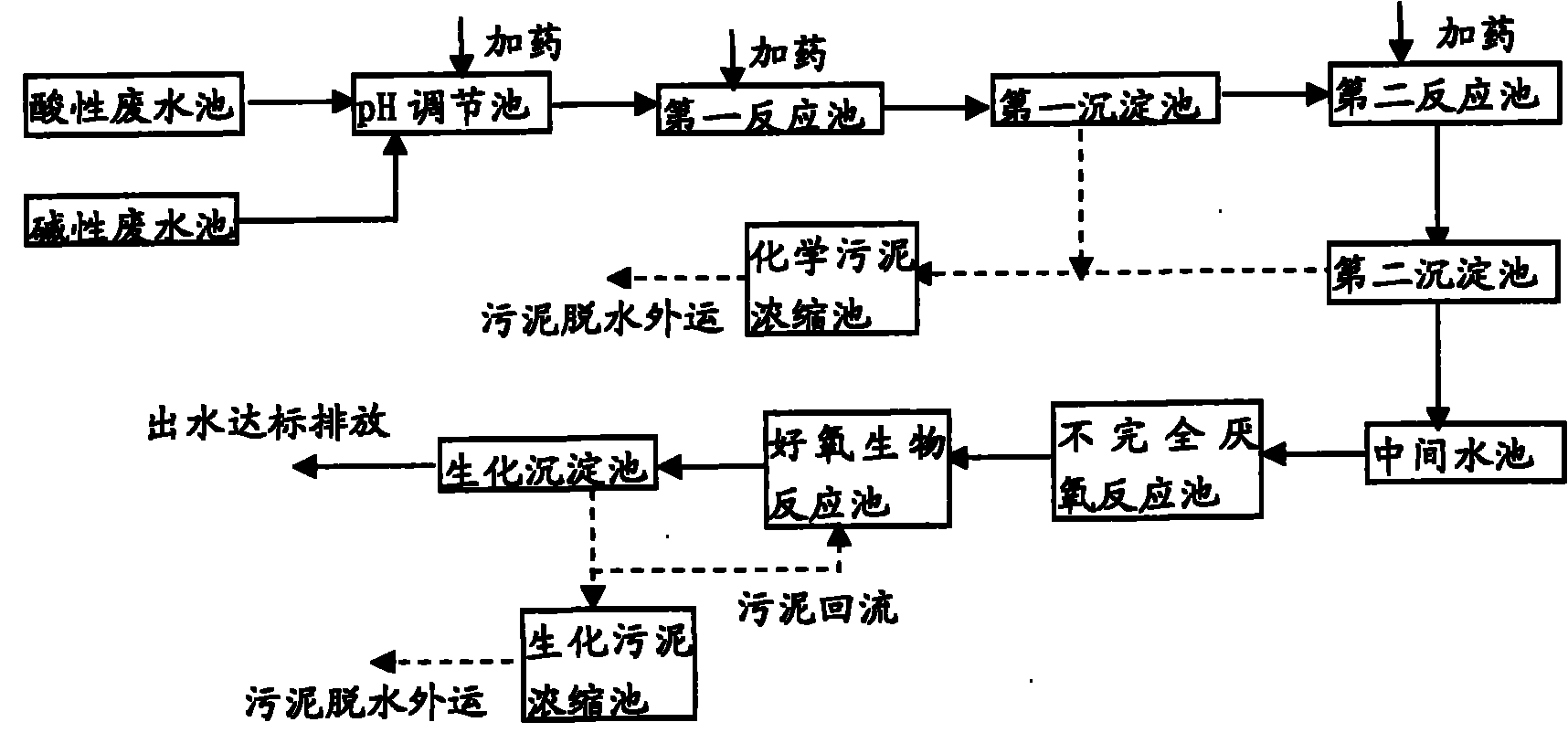

[0052] In a photovoltaic solar cell manufacturer, the acidic wastewater and alkaline wastewater generated during the production process were collected separately, and the acidic wastewater and alkaline wastewater were tested. The pH value of the acidic wastewater was 1.5, and the fluoride ion content was 4700mg / L. ; The pH value of alkaline wastewater is 13.1, COD Cr The concentration value is 5800mg / L.

[0053] The hydraulic retention time of the acid wastewater pool and the alkaline wastewater pool is about 8 hours respectively, and they are lifted to the pH adjustment pool by the lift pump for mixing. The pH adjustment pool has a built-in mixer. The on-line pH meter shows that the pH value after mixing is 4.9. Use the online pH meter to control the alkali-adding pump, and use the metering pump to add NaOH solution to adjust the pH of the mixed wastewater to between 8.0 and 8.5. The hydraulic retention time of the pH adjustment tank is 30 minutes.

[0054] After adjusting t...

Embodiment 2

[0063] Discharge of alkaline wastewater COD during the production of solar cells Cr 5000mg / L, pH12.3, acidic wastewater pH 1.2, fluoride ion concentration 5800mg / L. Acidic wastewater and alkaline wastewater are treated separately. The hydraulic retention time of the acid wastewater pool is 10h, and the hydraulic retention time of the alkaline wastewater pool is 8h.

[0064] The acidic wastewater is raised to the pH adjustment tank, and NaOH solution is added to adjust the pH to 8.0-8.5, and the effluent flows into the first reaction tank of the first defluorination unit by itself, and CaCl is added 2 About 29g / L, react for 30min, after the reaction, the wastewater flows into the first sedimentation tank by itself, and the hydraulic retention time is 2h. The effluent flows into the second reaction tank by itself, and CaCl is added 2 1000mg / L, add Al at the same time 2 (SO 4 ) 3 The flocculant is 200mg / L and the PAM coagulant is 8mg / L, and the reaction time is 30min. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com