Waste gas treatment device

A technology of waste gas treatment device and spray device, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separating agent, etc., which can solve problems such as effect to be improved and structural limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

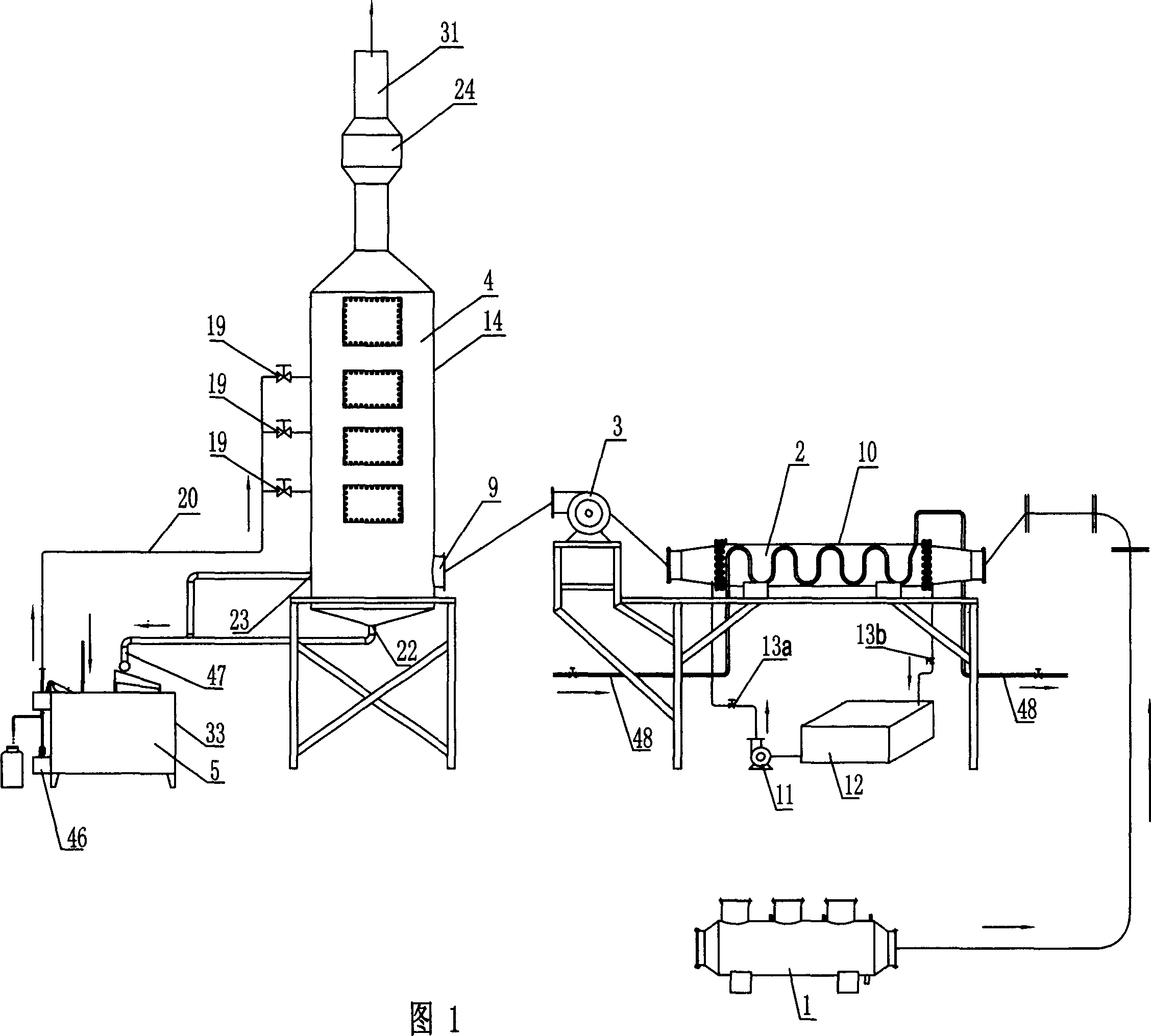

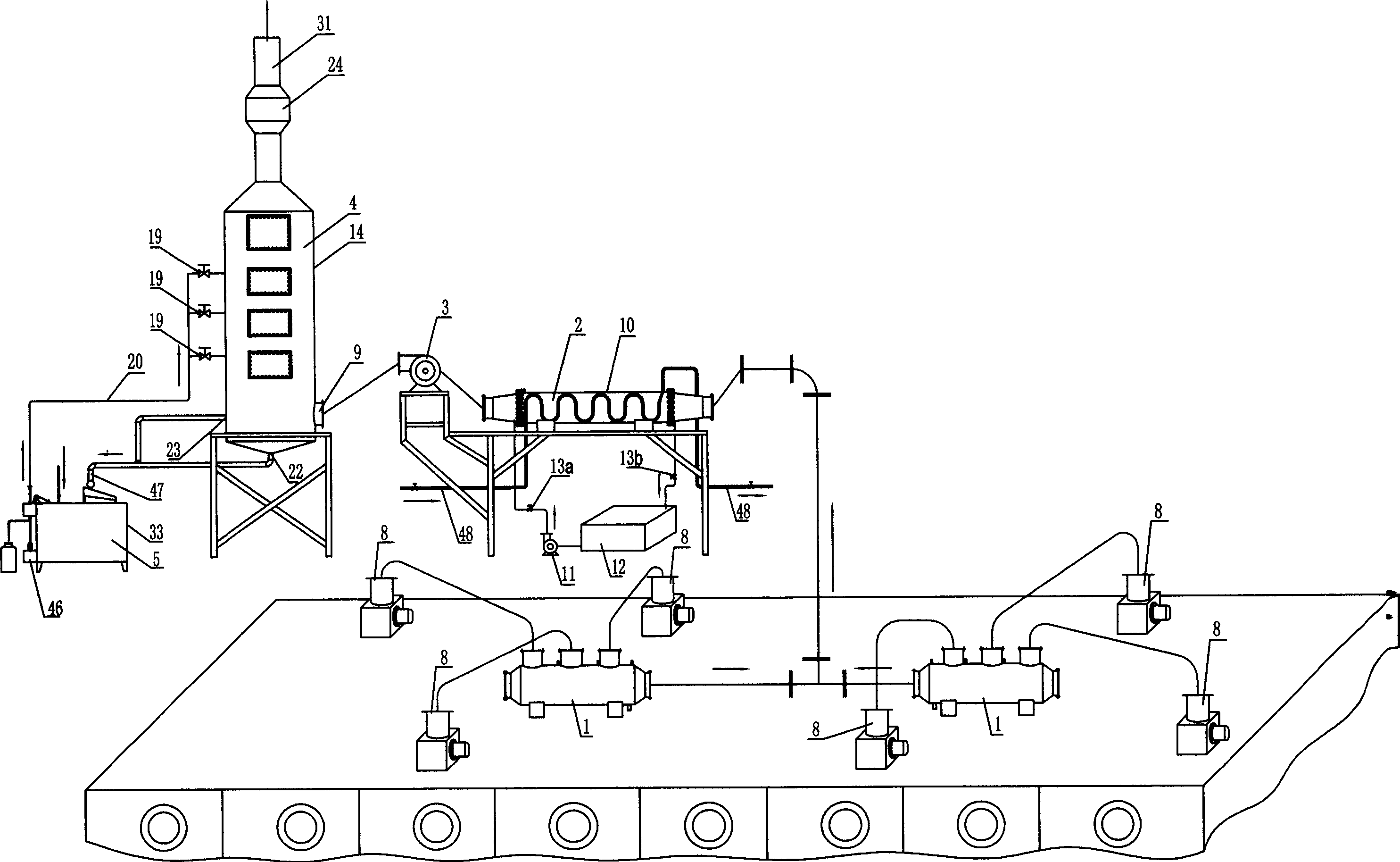

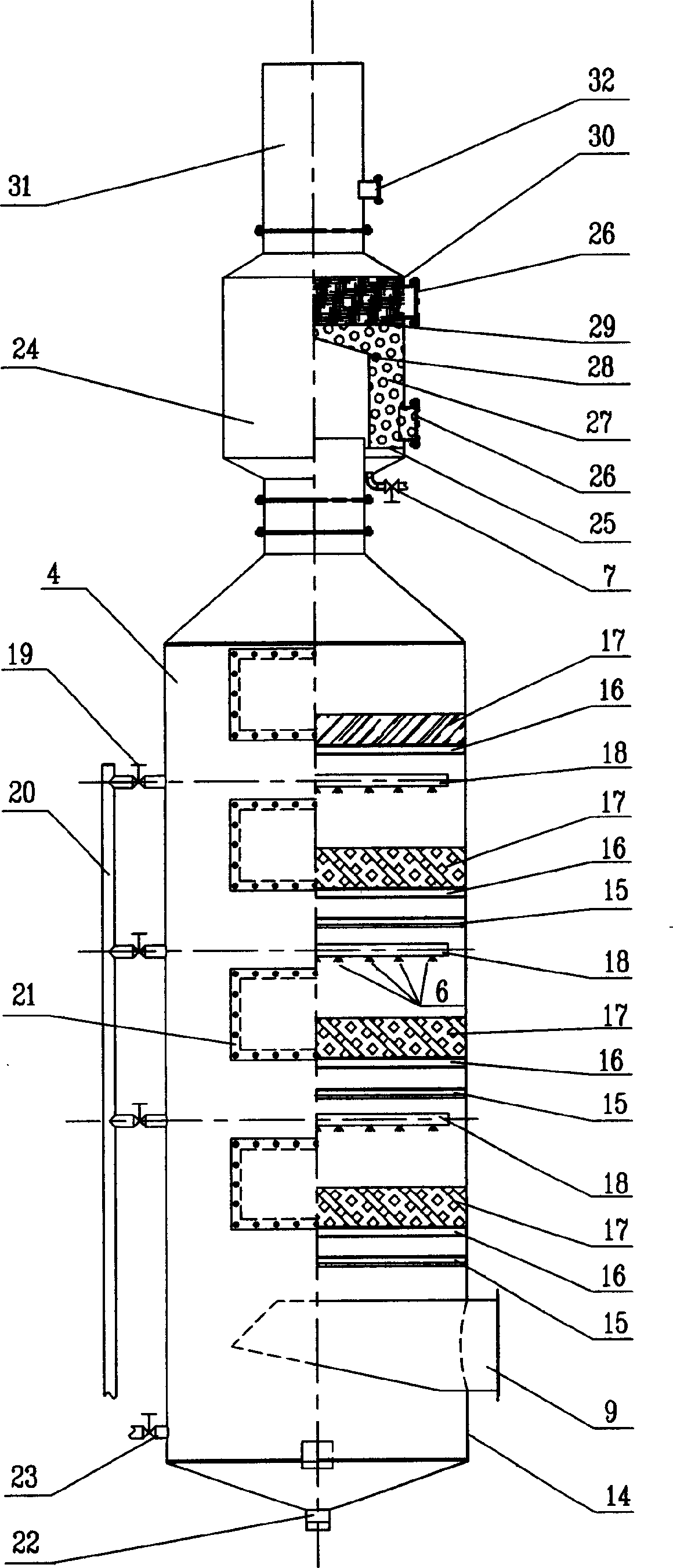

[0016] Figure 1, figure 2 As shown, the exhaust gas treatment device includes a flue gas concentrator 1, a heat exchanger 2, a spray packed tower 4, and an oil-water separator 5. One end of the heat exchanger 2 is connected to the flue gas concentrator 1 through a pipe, and the other end is connected to the flue gas concentrator 1 through a pipeline. The pipeline communicates with the air inlet 9 of the spray packed tower 4, and the oil-water separator 5 forms a circulation connection with the spray packed tower 4. image 3 Shown spray packing tower 4 comprises the tower body 14 that top is provided with mist eliminator 24, interior is provided with spraying device 18, and tower body 14 bottom and side are respectively provided with drain hole 22 and air inlet 9, tower An overflow hole 23 is also provided below the side wall of the body 14, and a water inlet distribution pipe 47 is connected between the drain hole 22 and the overflow hole 23, and the water outlet end of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com