Gas, liquid and light-weight oil triphase separating device

A three-phase separation and three-phase separator technology, applied in the directions of liquid separation, combined device, separation method, etc., can solve the problems of inability to meet production requirements, high energy consumption of separation equipment, unstable operation, etc., and achieve the solution of multi-phase mixing. problems, to achieve oil-water separation, to prevent the effect of carrying too much water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in detail, but in the description of the present invention, it should be understood that, the described embodiment of the present invention is exemplary, and the specific parameter that appears in the description is only for It is convenient to describe the present invention, but should not be construed as a limitation of the present invention.

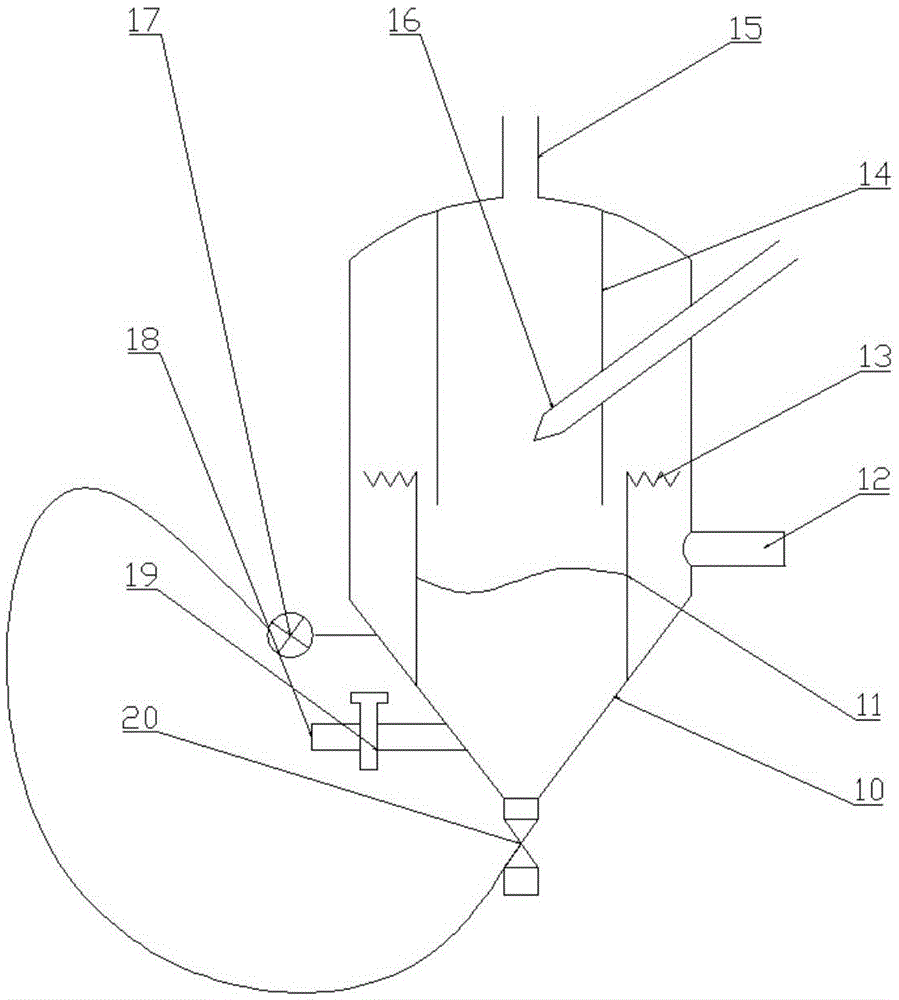

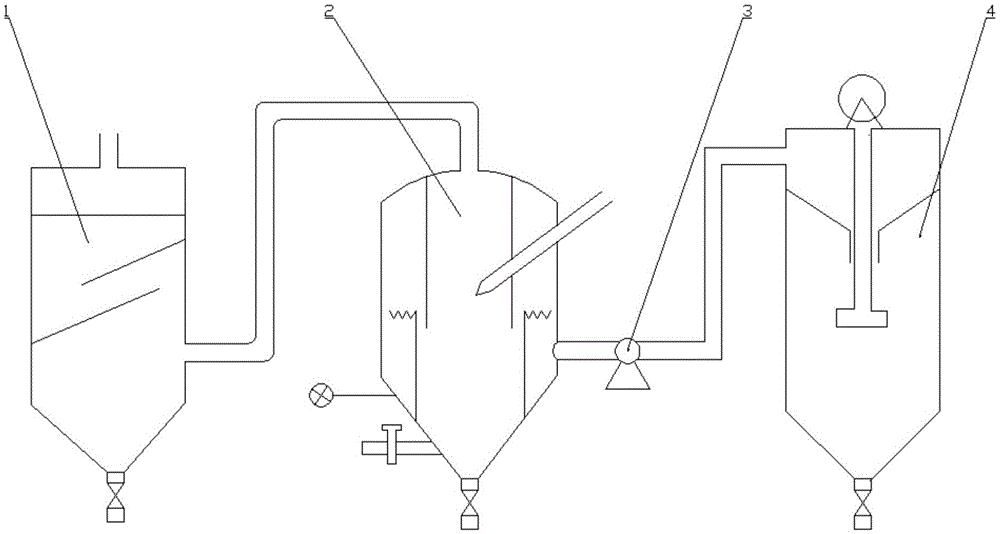

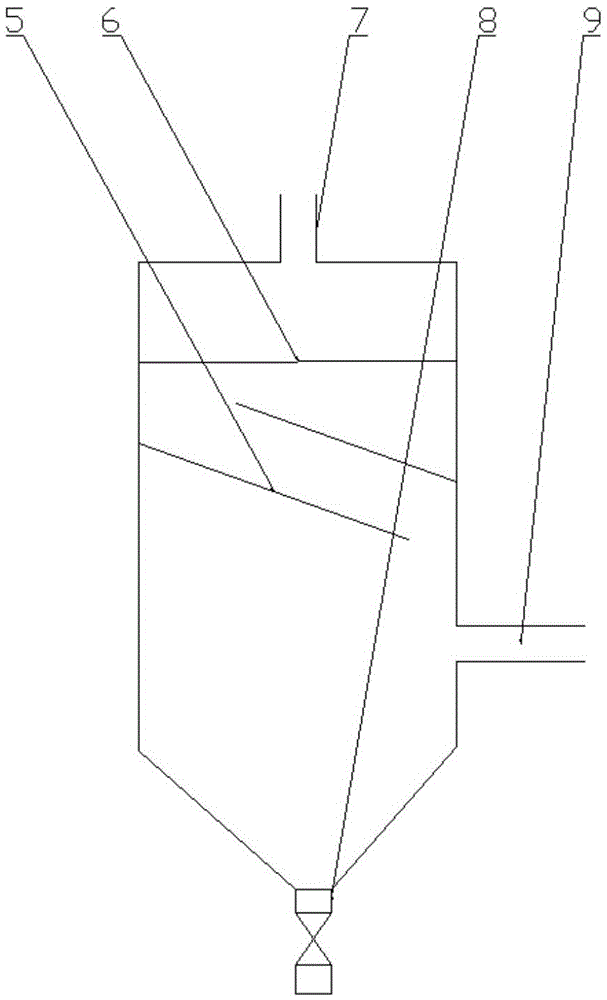

[0031] Such as figure 1 As shown, a gas-liquid light oil three-phase separation device of the present invention includes a three-phase separator 2. The middle part of the separation device is cylindrical, the lower part is conical, and the top surface is an arc surface. The structure of the three-phase separator 2 includes an external cylinder 10, an overflow cylinder 11, an oil discharge pipe 12, a corrugated overflow plate 13, an internal cylinder 14, an exhaust pipe 15, a three-phase mixture inlet pipe 16, and an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com