Method for preparing amphiphilic block copolymer modified polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride and copolymer modification technology, applied in the field of material science, can solve problems such as adsorption, achieve high filtration accuracy, improve hydrophilic properties, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

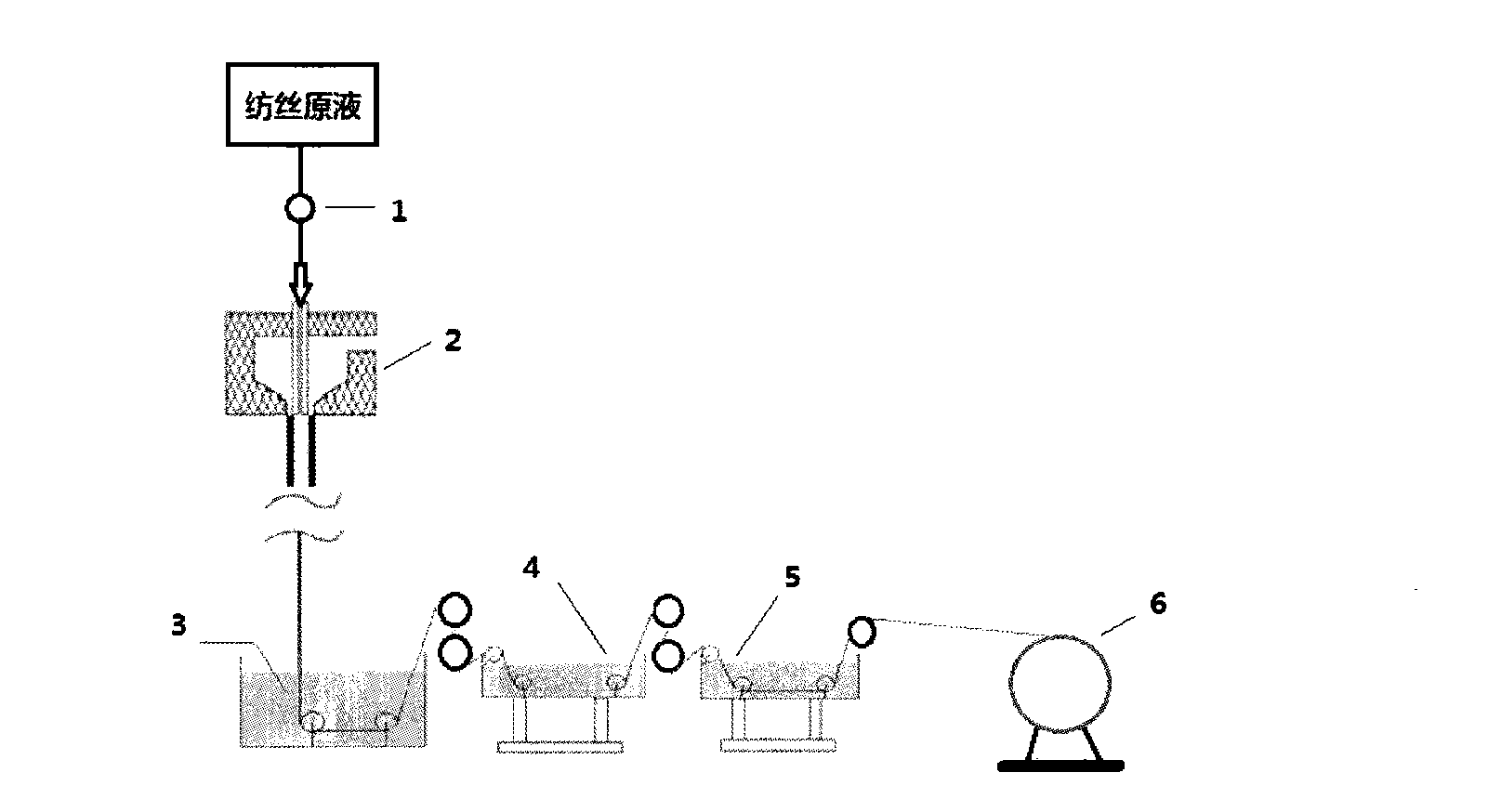

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of polyvinylpyrrolidone homopolymer:

[0043] Dissolve 2 parts of N-vinylpyrrolidone in 98 parts of 1,4-dioxane to make a 2% N-vinylpyrrolidone solution, and add 0.2 parts of S, S'-bis(α,α' -Methyl-α"acetic acid) trithiocarbonate, with 0.1 part of AIBN in N 2 Under protection, react at 60° C. for 4 hours to obtain a PVP homopolymer with a chain transfer agent terminal carboxyl group.

[0044] (2) Modification of polyvinylpyrrolidone homopolymer:

[0045] Dissolve 1 part of PVP homopolymer in 19 parts of dichloromethane to make a solution with a concentration of 5%, then add 2 parts of DCC and 8 parts of HOBT (based on PVP), then add 10 parts of Allylamine (based on PVP) was reacted at 0°C for 72 hours, and modified PVP was obtained after separation and treatment on a silica gel column.

[0046] (3) Modified PVP and organosiloxane polymer to generate block copolymer:

[0047] Dissolve 4 parts of modified PVP and 6 parts of vinyl polydimethylsiloxane i...

Embodiment 2

[0049] (1) Preparation of polyvinylpyrrolidone homopolymer:

[0050] Dissolve 100 parts of N-vinylpyrrolidone in 900 parts of 1,4-dioxane to make a 10% N-vinylpyrrolidone solution, and put 10 parts of S, S'-bis(α,α' -Methyl-α"acetic acid) trithiocarbonate, with 0.5 parts AIBN in N 2 Under protection, react at 80°C for 72 hours to obtain a PVP homopolymer with a chain transfer agent terminal carboxyl group.

[0051] (2) Modification of polyvinylpyrrolidone homopolymer:

[0052] Dissolve 1 part of PVP homopolymer in 1 part of dichloromethane to make a solution with a concentration of 50%, then add 8 parts of DCC and 4 parts of HOBT (based on PVP), and then add 50 parts of Allylamine (based on PVP) was reacted at 80° C. for 1 hour, and modified PVP was obtained after separation and treatment by silica gel column.

[0053] (3) Modified PVP and organosiloxane polymer to generate block copolymer:

[0054] Dissolve 3 parts of modified PVP and 7 parts of vinyl polydimethylsiloxane...

Embodiment 3

[0056] (1) Preparation of polyvinylpyrrolidone homopolymer:

[0057] Dissolve 30 parts of N-vinylpyrrolidone in 20 parts of 1,4-dioxane to make a 60% N-vinylpyrrolidone solution, and add 0.3 parts of S, S'-bis(α,α' -Methyl-α"acetic acid) trithiocarbonate, with 4.5 parts AIBN in N 2 Under protection, react at 60° C. for 72 hours to obtain a PVP homopolymer with a chain transfer agent terminal carboxyl group.

[0058] (2) Modification of polyvinylpyrrolidone homopolymer:

[0059] Dissolve 1 part of PVP homopolymer in 4 parts of dichloromethane to make a solution with a concentration of 20%, then add 4 parts of DCC and 4 parts of HOBT (based on PVP), and then add 40 parts of Styrylamine (based on PVP) was reacted at 25°C for 24 hours, and modified PVP was obtained after separation and treatment by silica gel column.

[0060] (3) Modified PVP and organosiloxane polymer to generate block copolymer:

[0061] Dissolve 6 parts of modified PVP and 4 parts of styrene-based polydimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bubble point pressure | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com