Method and facility for sorting and separating waste plastic

A technology for waste plastics and separation equipment, used in wet separation, solid separation, plastic recycling, etc., can solve the problems of low separation accuracy, difficulty in improving the separation accuracy of electrostatic separators, etc., to improve separation accuracy, prolong residence time and The effect of floating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Hereinafter, Embodiment 1 of the sorting and separating device for waste plastics of the present invention will be described with reference to the accompanying drawings.

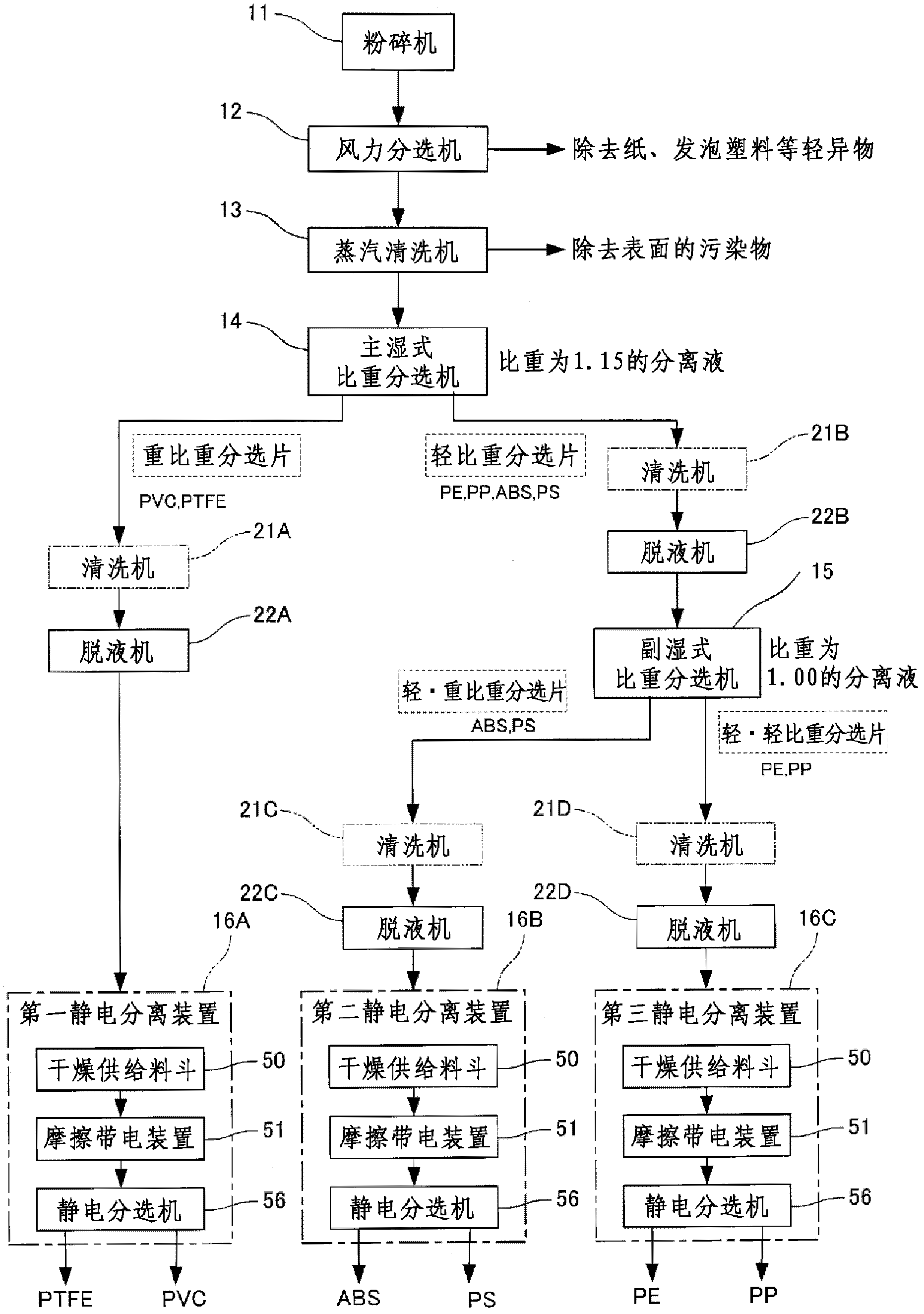

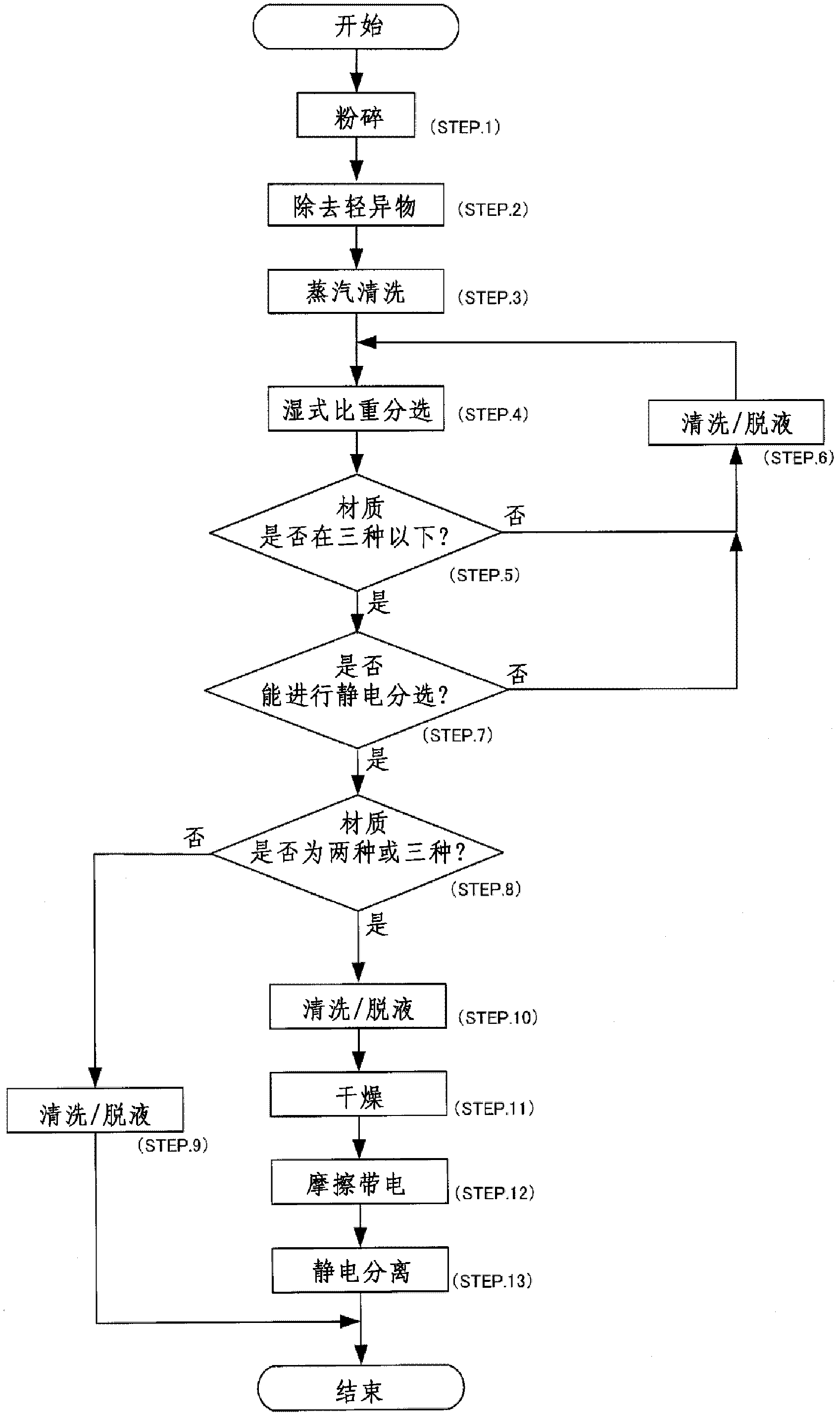

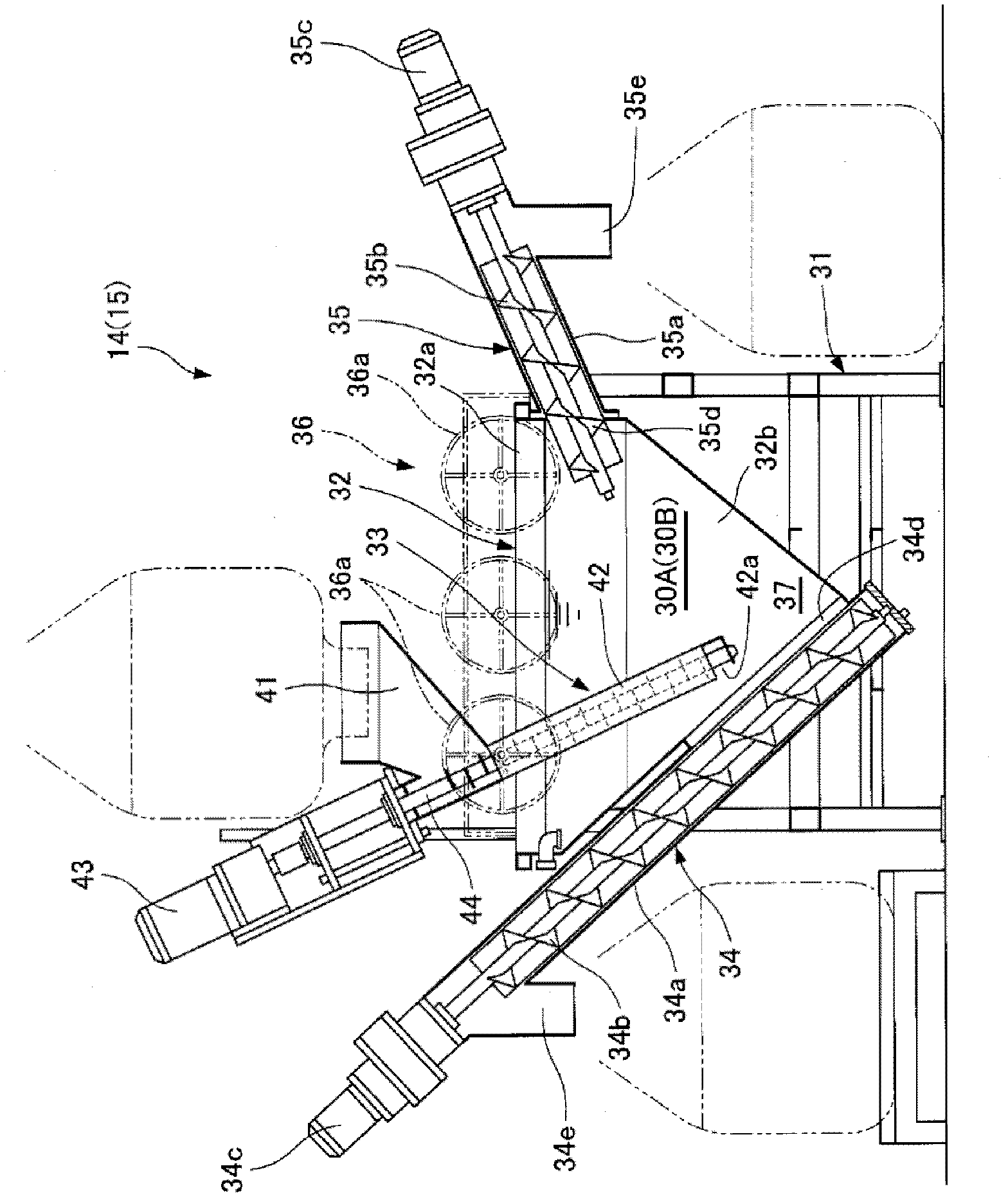

[0028] The sorting and separating equipment for waste plastics separates waste plastics such as waste household appliances and waste automobiles according to various materials contained in waste plastics, for example, six materials. like figure 1 As shown, the sorting and separating equipment for waste plastics includes a pulverizer 11, a wind separator 12, a steam cleaning machine (cleaning device) 13, a main wet specific gravity separator (wet specific gravity separator) 14, an auxiliary wet specific gravity separator machine (wet specific gravity separator) 15, cleaning machines 21A-21D, dehydrating machines 22A-22D, and first to third electrostatic separation devices 16A-16C. Furthermore, the first to third electrostatic separators 16A to 16C are respectively provided with a dry supply hopper (he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com