Single-tube interlaced inductively coupling plasma source

a plasma source and inductive coupling technology, applied in the field of plasma formation, can solve the problems of multiple defects in the structure, worsening conditions, and increasing reaction ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

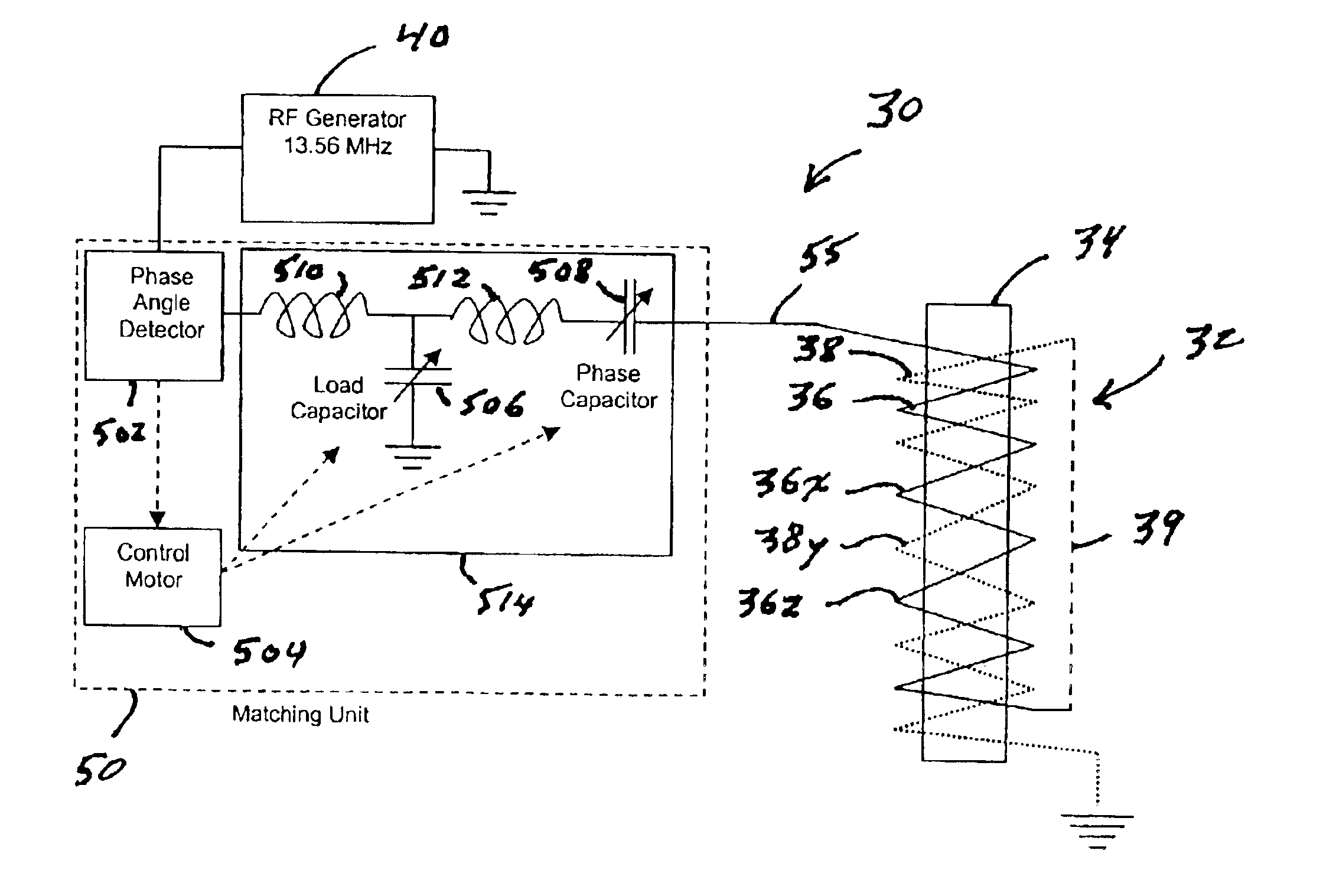

FIG. 3 is a schematic diagram of a plasma source 30 in accordance with this invention. Plasma source 30 includes a coil 32 which is wrapped around a tube 34.

Coil 32 is supplied by an RF generator 40, which operates at 13.56 MHz and which supplies a signal to coil 32 through an impedance-matching network 50. Impedance-matching network 50 includes a phase angle detector 502 and a control motor 504, which drives a load capacitor 506 and a phase capacitor 508 in an LC circuit 514. Circuit 514 also includes inductances 510 and 512, which are connected in series with phase capacitor 508. Matching network 50 is tuned to the impedance of coil 32 by minimizing the reflected power as seen by phase angle detector 502. The minimal reflected power is achieved through a tuning algorithm in which the positions of capacitors 506 and 508 are controlled by motor 504. To minimize the internal losses in matching network 50, capacitors 506 and 508 are preferably vacuum capacitors.

It should be understood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical inductance | aaaaa | aaaaa |

| Phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com