Method and device for predicting node temperature of shell and tube heat exchanger

A shell-and-tube heat exchanger and prediction method technology, applied in the field of heat transfer, can solve the problems of scattered functions, backward testing methods, low testing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

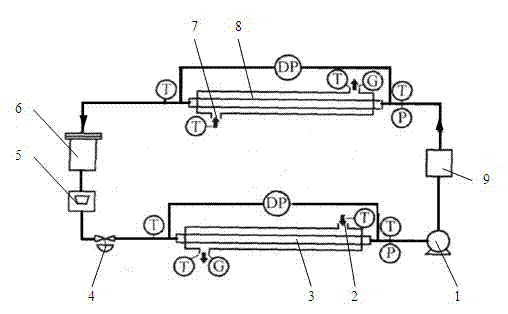

[0071] Embodiment 1: Example of single-tube heat exchange tube testing device of the present invention: as Image 6 shown

[0072] (1) Combined barrel sections 5, 7, 9, and 11 are used as the shell side shell. Each barrel section is composed of a round pipe, a flange at the end of the barrel section, and a connecting pipe at the upper and lower parts of the barrel section. The inner diameter of the circular tube is 1.5 to 2 times the outer diameter of the heat exchange tube 2 to be tested. The cylinder joints are connected by gasket bolt flange connection structure. By changing the number of cylinder sections, the axial length of the shell side can be changed to meet the test requirements of heat exchange tubes with different lengths. All parts are made of stainless steel, round pipe and connecting pipe, round pipe and flange, connecting pipe and flange are all welded.

[0073] (2) Connect a bellows barrel section 14 at one end of the barrel section. The corrugated tube...

Embodiment 2 test example

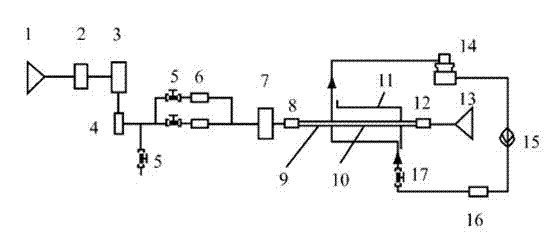

[0078] Embodiment 2: Example of the heat transfer performance test of the heat exchange tube of the present invention: as Figure 7 shown

[0079] (1) The inlet of the single-tube heat exchange tube testing device of the present invention is connected to the valve 3, and the temperature and pressure of the fluid at the inlet of the tube are measured by the temperature sensor 1 and the pressure sensor 2;

[0080] (2) The outlet of the heat exchange tube is connected to the valve 22, and the temperature and pressure of the fluid at the outlet of the tube side are measured by the temperature sensor 23 and the pressure sensor 24;

[0081] (3) The inlet pipe of the shell-side barrel section ( Image 6 Upper 6, 8, 10, 12) are connected with valves 7, 8, 9, 10 respectively. Valves 7, 8, 9, and 10 are connected to the shell-side flow distributor 6 through 4 hoses, and the lengths of the 4 hoses are the same to ensure that the fluid flowing from the shell-side flow distributor 6 fl...

Embodiment 3

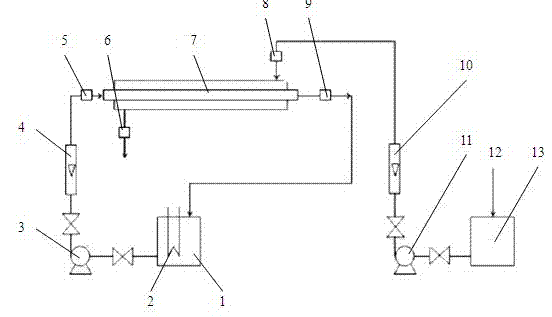

[0094] Embodiment 3. Example of node temperature prediction of the shell-and-tube heat exchanger of the present invention: as Figure 8 shown

[0095] (1) According to the geometric characteristics of the shell-and-tube heat exchanger, the heat exchange tube bundle is divided into several sections by the baffle, such as Figure 8 As shown, the flow direction of the shell-side fluid is perpendicular to the flow direction of the tube-side fluid. Neglecting the influence of the particularity of fluid flow and heat transfer in the tube layout area near the wall of the cylinder on the overall performance of shell side flow and heat transfer, the shell side fluid has periodic characteristics in the horizontal direction, so a periodic heat exchange tube bundle can be used for temperature field analysis . The number of heat exchange tubes in the vertical direction of the heat exchange tube bundle of this cycle is the same as that of the actual heat exchanger, and the number of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com